BWT Retrofit Install On Offshore Supply Vessel

3D scanning, design, fabrication and installation with zero vessel downtime

The vessel owner approached Goltens to assist them in installing an Optimarin ballast treatment installation on their offshore supply vessel. As the vessel was on a long-term contract, keeping the vessel in service was critical.

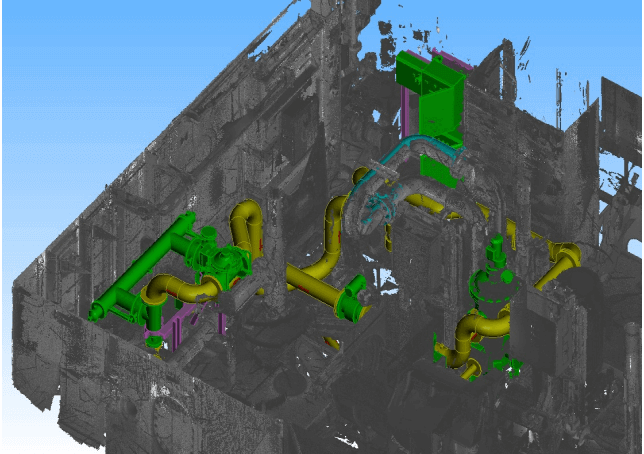

Goltens used 3D laser scanning to perform an on-board survey and create highly accurate 3D models. Once baseline modeling was completed, Goltens provided the detailed engineering for all piping, foundations and other steelwork.

With the engineering completed, it was now possible to prefabricate and stage all the necessary parts for installation. Because of the accuracy of the laser scan, engineering and the pipe fabrication (±2.00mm) components were fitted without further modifications or additional delay

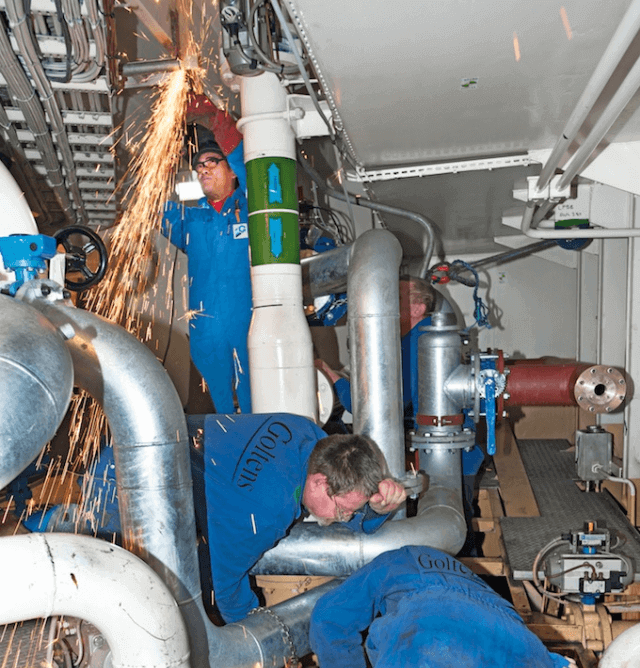

During three short port-stays, the installation was finalized and successfully commissioned afterwards by Optimarin.

PROJECT FACTS

| M/V Highland Eagle | |

|---|---|

| Ballast flowrate: | 150 m³/hr |

| Total ballast capacity: | 767 m³ |

| Ballast treatment system: | Optimarin OBS 167 m³/hr |

REPAIRS

- 3-D Scanning and Modeling

- Detailed engineering

- Prefabrication of all required components

- Installation of new ballast piping and connection to the ballast treatment equipment

- Pulling cables for the new electrical connections

- Adding new cable trays and hooking up to the vessels automation system

- Connecting deaeration piping up to the main deck

- Making a new overboard connection with the assistance of divers – no drydocking needed

- Placing extra supports to prevent vibration of existing and new piping

- Pressure testing all new piping

RESULTS

Goltens completed this installation job with zero downtime for the vessel.

The owner was very pleased with the result and engaged Goltens Green Tech for subsequent retrofit assistance on other vessels.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now