Exhaust gas scrubber tower installation for cruise ship in 18 days

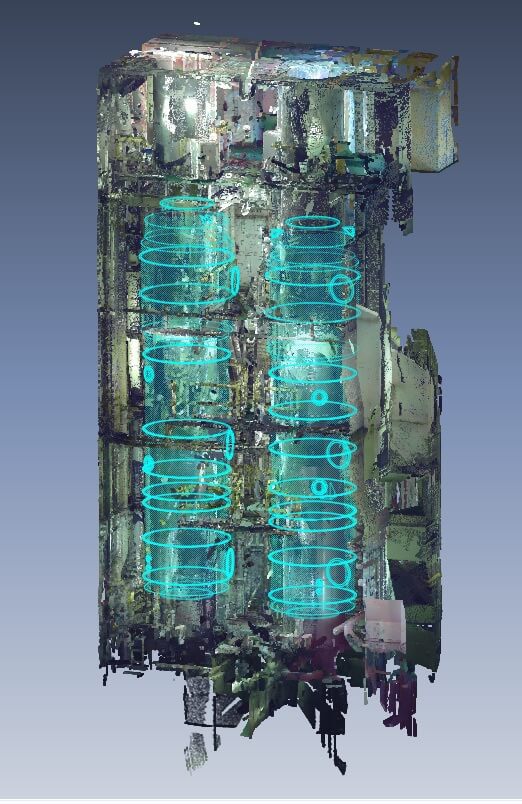

3D laser scanning , feasibility study, detailed design engineering , pre-fabrication and installation of 2 exhaust gas scrubber towers

Goltens was engaged by a large cruise vessel owner to undertake the installation of 2 exhaust gas scrubbers on one of their cruise ships to comply with Sulphur Emissions regulations. The vessel is equipped with 4 GMT/Sulzer 16ZAV40S and two GMT/Sulzer 12ZAV40S diesel electric generating sets.

The scope of the project was to perform all evaluation, planning, design and installation for two 10+ meter long exhaust gas scrubber towers on Diesel Generator #1 and #2 and complete the entire operation before the completion of its drydock period in the United States.

DETAILED PLANNING AND PREPARATION:

Goltens’ Technical Management attended the vessel to evaluate the project, determine space requirements and logistical obstacles. Additionally, leveraging the well- proven Goltens Green Technology process, undertook 3D laser scanning of the spaces to facilitate system modeling. Once 3D modeling was complete, Goltens was able to complete the detailed design and map out a definitive process, manning plan and timeline for the removal of the existing exhaust silencers and the installation of the exhaust gas scrubbers within the timeline required.

Additionally, based upon the detailed design, Goltens was able to prefabricate foundation structures in its workshop and ship the prefabricated material to the vessel in time for its arrival in the drydock.

PHASED APPROACH FOR SCRUBBER INSTALLATION:

Goltens mobilized a 10 man riding crew to perform demolition and prepare engine casing for the rigging and installation operations. Despite a 3-day delay in beginning dismantling work caused by operational demands for the engines, all preparatory work was completed during a nine day underway period prior to docking.

Once in drydock, Goltens mobilized a team of more than 40 technicians (100% American Labor) and technical managers to site to complete the project within the 10 day drydocking period. After an initial 24-hour delay due to sever weather, the team removed all 8 Exhaust Silencers and installed all Scrubber Tower sections within 22 hours, before the crane was struck due to another storm. Goltens ran two shifts with a minimum of two supervisors per shift to ensure that quality controls and safety standards were adhered to throughout the project.

PROJECT FACTS

| EXHAUST GAS SCRUBBER | |

|---|---|

| Number of Scrubber Towers: | Two |

| Engine Type: | GMT/Sulzer 16ZAV40S |

| Vessel Type: | Cruise |

| Installation Duration: | 18 Days |

EXHAUST GAS SCRUBBER INSTALLATION SCOPE

- Detailed Vessel Survey and Ship Check

- 3-D scanning & modeling used for feasibility study of access routes & precise study of final equipment locations

- Detailed engineering using Goltens generated 3D models and plans from the tower manufacturer

- Prefabrication of foundation structures

- Preparation of Access Routes while vessel was underway

- Exhaust Gas Silencer dismantling and removal

- Preparation of Casing for installation route

- Mounting and assembly of the 2 Scrubbers including necessary modification and reconnection of exhaust gas piping

- Installation of all required Insulation and Cladding

EXHAUST GAS SCRUBBER INSTALLATION RESULTS

Despite significant delays caused by severe weather conditions at the beginning of the drydocking, Goltens was able to keep the schedule working around the clock to complete the installation. Goltens worked very closely with the vessel’s technical project management to overcome schedule delays caused by weather and technical obstacles encountered. As a result, the project was completed a day ahead of schedule and the vessel was able to leave the drydock as planned.

As a result of the successful completion of the job, Goltens was awarded and completed a similar job for a sister vessel a few months later.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now