Goltens solves complex rudder stock problem for Ben Kien shipyard

M/V 9200T-03 – The rudder stock rectification

Goltens has a long history of taking on the most challenging workshop machining and rectification works and providing our customers with a full package solution.

M.V 9200T -03 is a new build vessel in Ben Kien shipyard- Hai Phong in the North of Vietnam. Prior to installation of the rudder stock on the vessel, it was found that some heavy corrosion had taken place on the shaft surface. The ship owner required that the shaft be returned to a new condition prior to installation and that the procedure had to be approved by BV class.

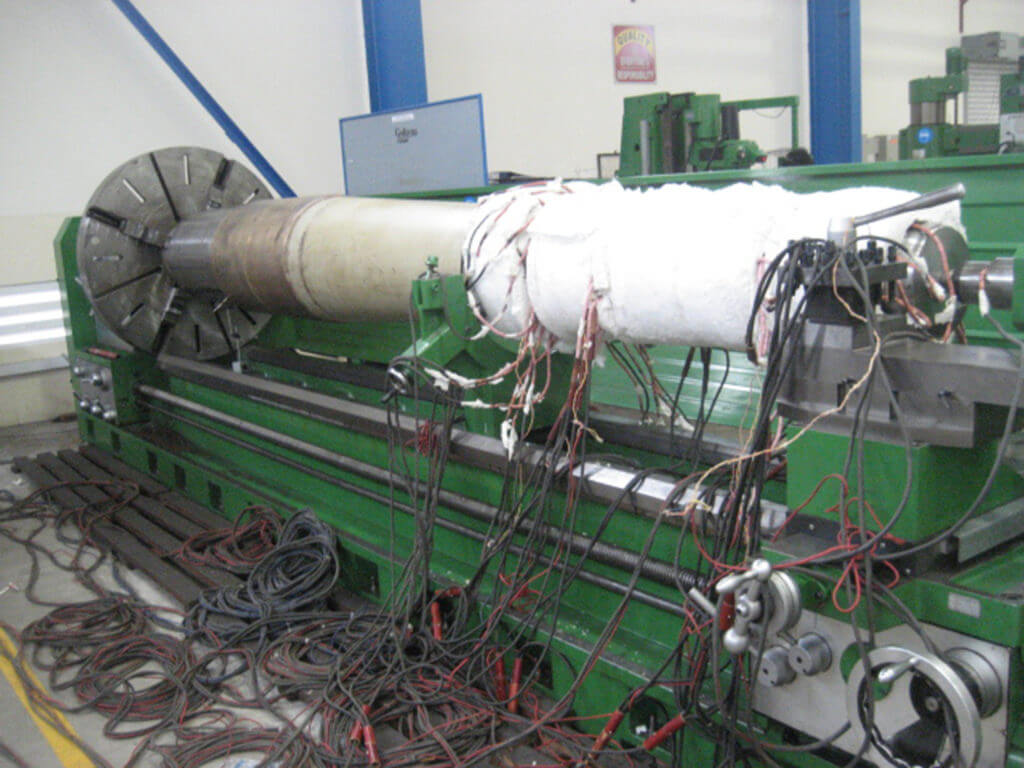

The shipyard was unable to find a local repair company to handle this work as a complete repair package with an acceptable procedure. Goltens Vietnam based in Vung Tau in the South of Vietnam was able to propose a procedure that was accepted by BV Class. This involved removal of defective material, heating the shaft using Goltens’ annealing equipment , rebuilding the defective area and machining it back to original size.

PROJECT FACTS

| BEN KIEN SHIPYARD | |

|---|---|

| Vessel: | M/V 9200T-03 |

| Rudder stock Length: | 4.610m |

| Rudder stock diameter: | 300/400/545/350mm |

| Rudder stock weight: | 9500 kg |

| Machined length of Shaft: | 770mm |

WORKSHOP REPAIRS

- Rudder stock cleaned & measured (before & after repair)

- Completed alignment check & machining on long bed lathe

- PMI inspection prior to welding

- Heating and welding following set procedure

- Heat treatment of rudder stock

- Final machining and polishing of rudder stock

- Final inspected by MPI and UT

RUDDER STOCK REPAIR RESULTS

Goltens repair package solution was presented to ship owner and completed within the expected schedule of 7 days with excellent results achieved. The vessel owner, Bureau Veritas class surveyor and the shipyard QC engineer approved the entire repair.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now