In-Situ annealing and machining restores Panamanian powerplant

Wartsila W18V46 generator

A Panamanian power plant experienced a casualty resulting from a big end bearing failure on unit #8 on diesel generator #5. As a result of the casualty, the crankpin journal surface was severely damaged and due to the rapid cooling of the crankpin post casualty, high hardness was suspected.

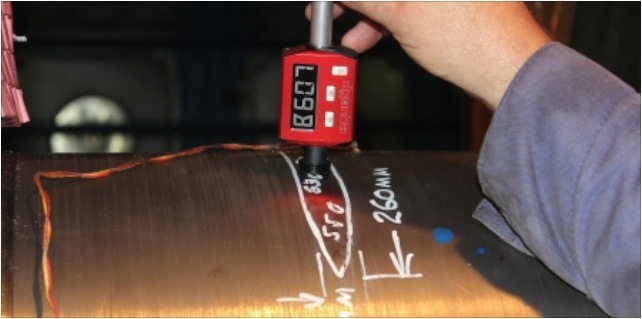

Goltens In-Situ specialists evaluated the extent of the casualty, checking the crankpin for cracks and hardness and determined that surface cracks were present and that hardness values over 600 Brinell were present. Additionally, grooves and white metal from the bearing were welded crankpin journal’s surface.

Goltens’ machinists removed 2.00mm from the diameter to eliminate the surface cracks but found the hardness was not reducing significantly. Based upon the extent of the hardness, Goltens estimated that it could extend as deep as 8.00mm or more. In order to salvage the crankshaft at the largest possible diameter Goltens recommended annealing (heat treatment) of the journal to reduce the hardness to acceptable levels and finish machine at a much larger diameter.

ANNEALING PROJECT FACTS

| Panamanian Power Plant | |

|---|---|

| Engine Make/Model: | Wartsila W18V46 |

| Engine Output: | 10,000 HP |

| Crankpin Dia. Pre machining: | 450.00mm |

| Crankpin Dia. Post machining: | 447.00mm |

| Distance between Webs: | 450.00mm |

DIESEL GENERATOR REPAIRS

- Full NDT inspection (Magnaflux and Hardness)

- Machining of crankpin #8 to -02.00mm undersize preannealing

- Annealing of crankpin #8 to reduce hardness to below 325 Brinell

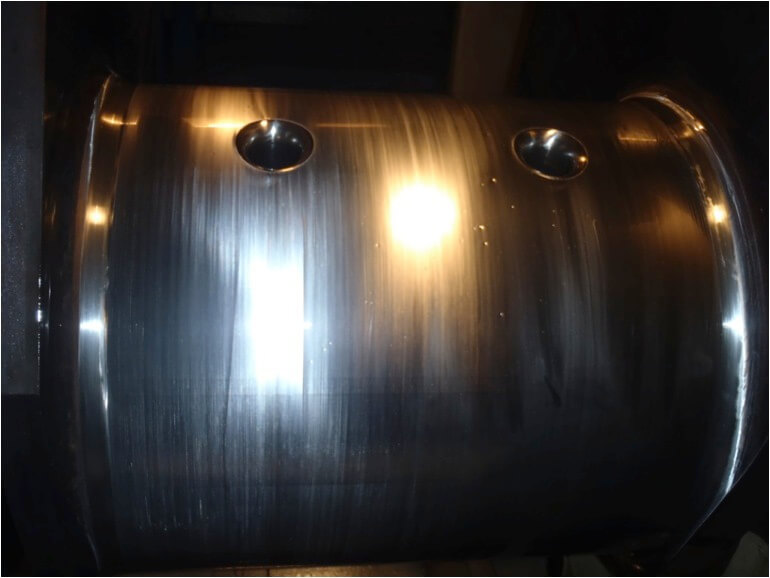

- Finish machining to -03.00mm at 447.00mm

- Superpolishing crankpin #8 to less than 0.3Ra

IN-SITU RESULTS

Goltens was able to salvage the crankshaft at a much larger diameter than would have been possible without application of Goltens’ annealing process. This eliminated the time and cost associated with machining the crankshaft to a much smaller diameter and left the engine in a much better long term condition, much to the satisfaction of the customer.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now