In-Situ annealing saves crankshaft condemned by the engine maker

MAN B&W 6L48/60 main engine casualty

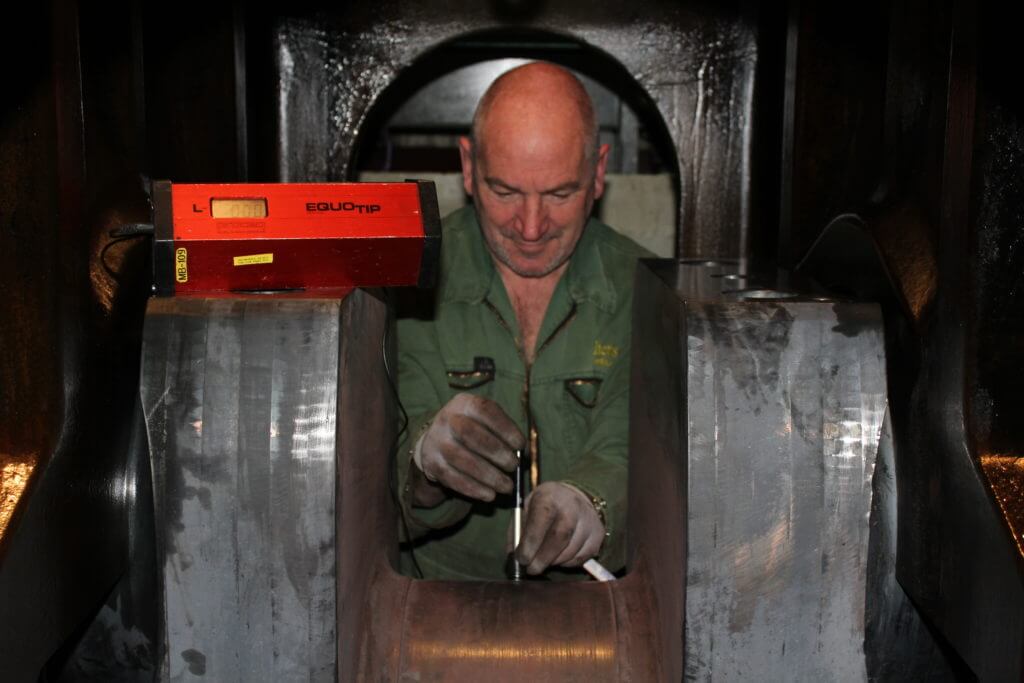

Goltens was called upon to inspect a crankpin badly damaged by a bearing failure on the containership’s MAN 6L48/60 main engine. The company inspected the 415mm- diameter journal, performing magnaflux and hardness tests and checking the run out on the shaft.

It was found that the run out on the shaft was 0.11mm versus a maximum of 0.09mm as allowed by MAN. Hardness values were also as high as 700 Brinell, which was well beyond the maker’s limits.

Local grinding was also performed, and it was determined that the cracks did not penetrate below the 5mm undersize — the smallest diameter for which standard undersized bearings were available. Goltens informed the owner that it believed the crankshaft could be saved at -5mm — despite the surface cracking, slight bend and excessive hardness resulting from the casualty — via annealing and peening of the shaft.

Subsequent inspection by the engine maker confirmed the previous findings. However, as MAN does not approve of annealing and peening to reduce hardness and straighten its crankshafts, the shaft was condemned by the maker.

THE DECISION

Goltens machined the crankshaft to -4mm and to evaluate the condition of the shaft. It was determined that the hard spots did not lessen – in fact, they became worse. All of the surface cracks were removed, with the exception of a few that could be locally ground and not exceed the -5mm target. Goltens was now confident that they could salvage the crankshaft at -5mm.

Due to the excessive hardness on the journal and the requirement to peen the shaft to straighten it, Goltens worked closely with Germanischer Lloyd (GL) to gain approval for a slight modification to its GL-approved process. The owner then gave Goltens the order to proceed with the annealing and peening of the shaft to restore it to the required tolerances. The process modification helped improve the effectiveness of the annealing procedure, which would be key in reaching the 350 Brinell upper limit set by MAN.

THE REPAIR

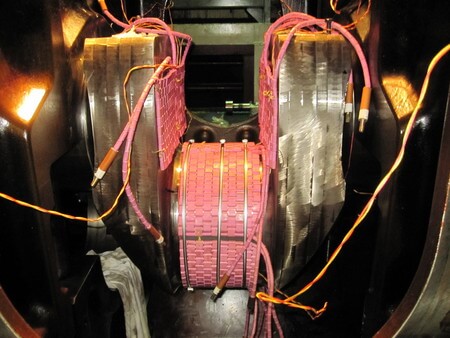

Goltens mobilized its annealing equipment while engine preparations were being carried out. To ensure that no ancillary engine damage occurred from the linear expansion of the crankshaft or the heat from the annealing itself, Goltens instructed the owner to ensure that the flywheel, gear wheel and other vulnerable components were removed prior to starting the process.

NO LENGTHY DOWNTIME, NO LARGE EXPENSE

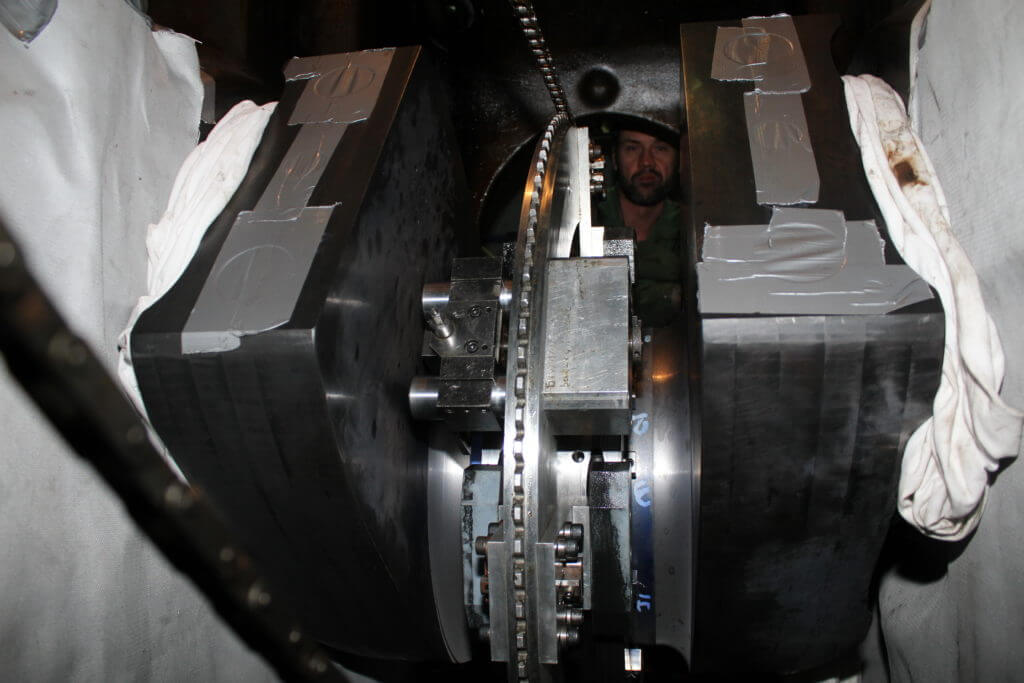

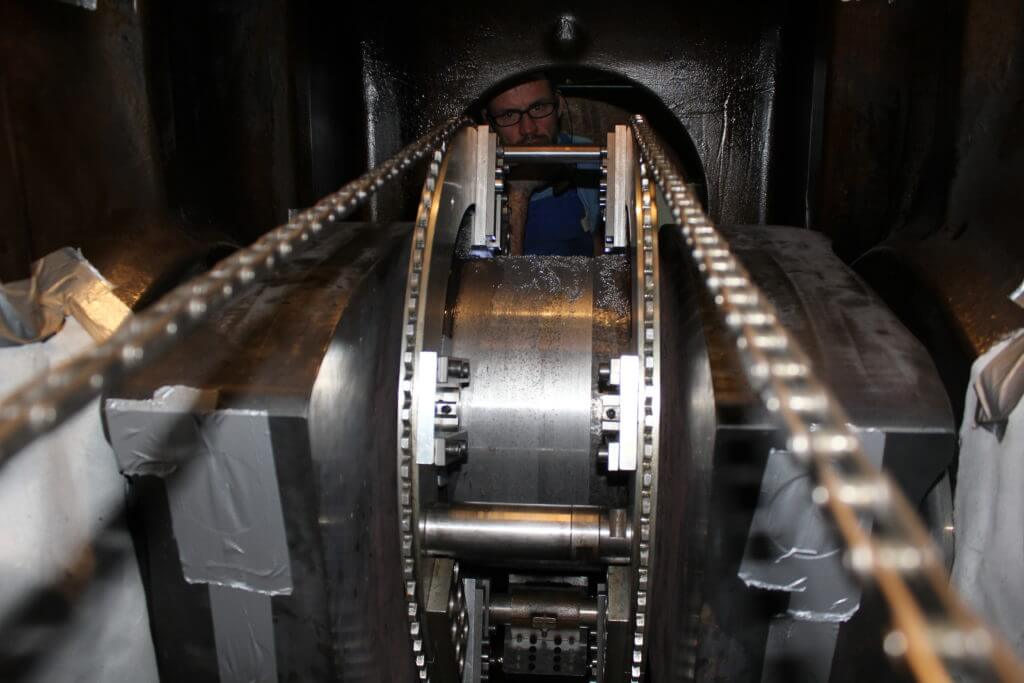

Once preparations were taken care of, Goltens completed the annealing of the crankpin and subsequent testing showed that the hardness had been successfully reduced to below 300 Brinell. The shaft was then carefully peened and the straightness of the shaft was restored. Goltens then set up its single-point cutting tools, finished machined the journal to -5mm and then machine polished it to its finished surface.

PROJECT FACTS

| MAN 6L48/60 ANNEALING | |

|---|---|

| Ship Type: | Containership |

| Journal Diameter Pre-Machining: | 415mm |

| Final Journal Diameter: | 410mm |

| Max Hardness Pre-Annealing: | ~700 HB |

| Max Hardness Post- Annealing: | <300HB |

IN-SITU MACHINING REPAIRS

- Magnaflux and hardness checks on all crankpins

- Pre-annealing machining of crankpin 411.0mm to remove surface cracks

- Local grinding of small remaining cracks

- Annealing of crankpin

- Machining of the fillet radii

- Machining and polishing crankpin to 410.00mm (-5.00)

- Polishing of all other main journals and crankpins

IN-SITU ANNEALING & MACHINING RESULTS

Final inspections were then completed and measurements were taken and verified by both owner and class. Upon installation of the undersized bearing and completion of additional required work, the engine could be restored to operation. All of this without the lengthy downtime and large expense of an unnecessary crankshaft replacement…

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now