In-situ laser cladding & machining for Shanghai steam plant

Siemens THDF125/67 turbine valve casing assembly renewal

Creating innovative in-place machining solutions that minimize asset downtime and repair costs is what Goltens is known for and has been doing for over 75 years. So when Shanghai Waigaoqiao Power Plant II approached Goltens for an in-place solution to recondition steam valve seats, Goltens stepped up to the challenge.

The plant’s two 900 MW Siemens THDF 125/67 coal-fired supercritical thermal units each had two HPSV, HPCV, ISV and ICV valve seats that required renewal. The challenge was to machine the original material and remetal the seats in-place prior to machining them back to original size.

SOLUTION DEVELOPMENT

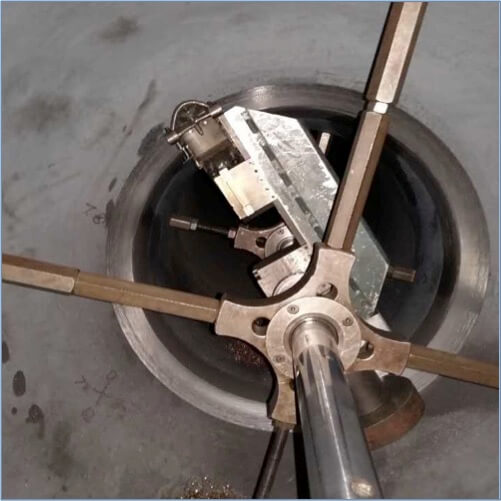

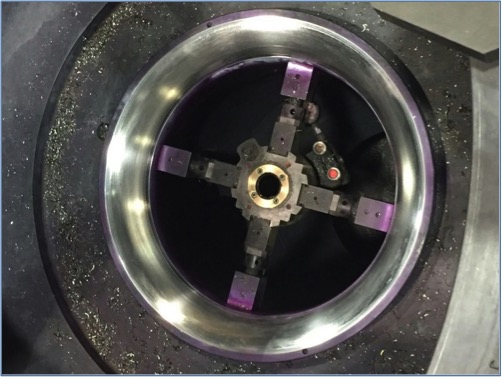

Goltens proposed a detailed solution using its traditional in-place machining coupled with a low surface temperature laser cladding technology.

To prove out the viability of the proposed repair, the repair process was tested on a scrap valve in Goltens’ Shanghai facilities. Based on the test results, modifications were made to the equipment to allow a smooth and delay free job once on site. Goltens then produced a detailed procedure and reviewed it with the customer prior to mobilizing for the job.

REPAIR SCOPE

For each of the HPSV, HPCV, ISV and ICV valves, the repairs consisted of:

- Pre-machining the valve seat

- Laser cladding with basic material (X10CrMoVNb9)

- Coating the cladded surface with EOS Nickel Alloy In625

- Finish machining the valve seat to original dimension

EARLY COMPLETION OF THE REPAIRS

Goltens’ team completed the job in 32 days, delivering the completed valves back to the customer 6 days earlier than planned.

The excellent work delivered by Goltens Shanghai makes them the preferred choice for upcoming follow on work at Shanghai Waigaoqiao Power Plant III.

PROJECT FACTS

| TURBINE VALVE REPAIR | |

|---|---|

| Customer: | Shanghai Waigaoqiao Power Plant |

| Location: | Shanghai, China |

| Turbine: | SIEMENS THDF125/67 |

| Plant Capacity: | 2 units × 900MW |

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now