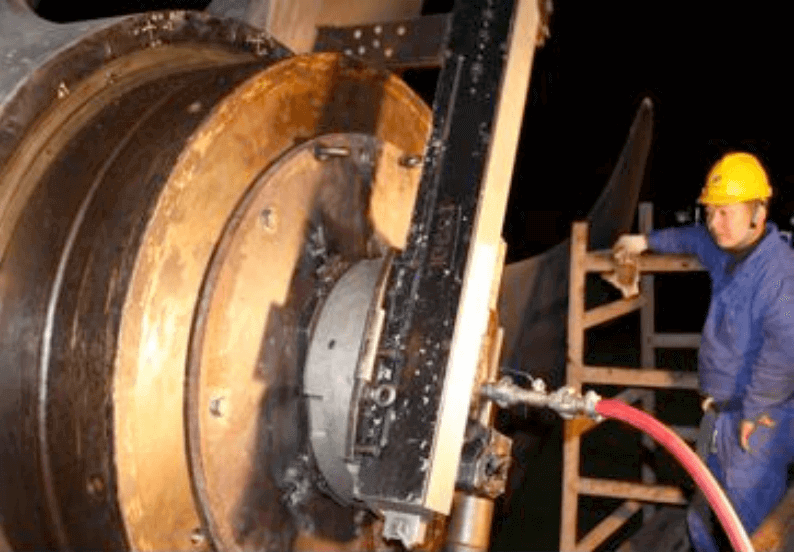

In-Situ machining of propeller hub

In-Situ machining avoids costly shop repair and extended docking

Goltens was contacted to evaluate damage observed on a drydocked vessel during a yearly propeller survey at CSIC shipyard. Goltens was engaged and performed a visual evaluation of the hub followed by dye penetrant checks to determine if there were cracks on the hub as well as the wear and scraping observed.

Inspection revealed that the hub did require reconditioning and Goltens proposed that the repair be done in-situ to avoid the cost and time associated with disassembly and reassembly of the propeller as well as avoided transport costs and extended docking time.

Goltens mobilized its tools and technicians and worked around the clock to complete the repair.

PROJECT FACTS

| PROPELLER HUB | |

|---|---|

| Vessel: | M/V XIN YA ZHOU |

| Engine: | MAN B&W 12K98MC-C |

| Tonnage: | 102,396 DWT |

| Hub Outside Diameter: | 1600.00mm |

| Hub Inside Diameter: | 1393.00mm |

REPAIRS

- Dye penetrant checking for cracks on propeller hub

RESULTS

Goltens technicians completed this job within 2 days with 2 shifts working around the clock to keep up with vessel’s drydock schedule. Goltens saved the extra dry-dock time and cost for the ship owner, which would have been needed to pull the propeller and machine the hub in the workshop.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now