Crankshaft bearing failure: journal annealing and machining

MAN B&W V9V40/54

Goltens was contacted to attend a general cargo ship in Italy that had suffered bearing damage from overheating on its MAN/B&W V9V40/54 engine.

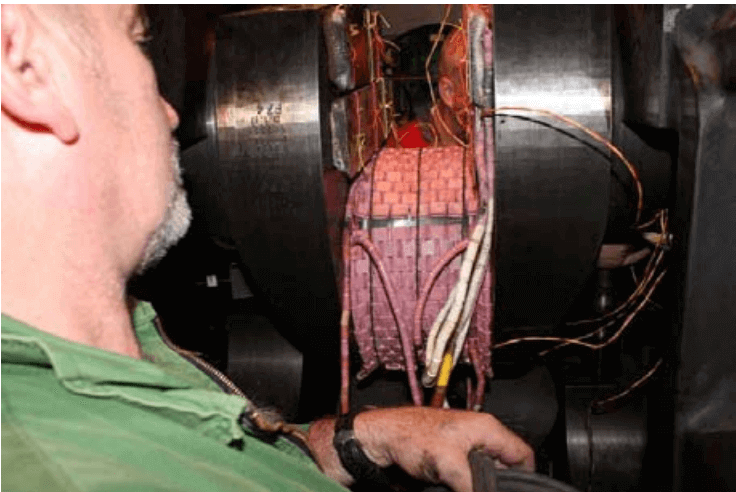

Inspection revealed cracks in the journal surface as well as damaged fillet radii. Goltens in-situ machinists performed local grinding to determine the depth of the cracks and hardness testing to determine whether or not the hardness levels were acceptable.

Hardness testing revealed extreme hardness in BDC of crankpin Nr.5 – hardness measured max. of 630 HB. Based upon the depth of the surface cracks and the hardness Goltens informed the owner that we could remove the hardness with annealing and salvage the shaft at 4-5mm undersize. As the maximum undersize was -5.0mm, without annealing, the crankshaft would be condemned.

Goltens machined new fillet radii and rough machined the journal to remove all surface cracks and completed annealing of the crankpin. Post heat treatment hardness measured between 314 and 320 Brinell.

The crankpin was finish machined to a diameter of 316 mm (- 4.0 mm) well within maker limits.

PROJECT FACTS

| MAN B&W V9V40/54 | |

|---|---|

| Crankpin Diameter: | 320 mm |

| Pre Annealing Hardness: | 630 Brinell |

| Post Annealing Hardness: | 320 Brinell |

| Finished Crankpin Diameter: | 316 mm (-4.0mm) |

CRANKSHAFT ANNEALING AND MACHINING REPAIRS

- Machining of new fillet radii

- Magnaflux crack testing and Hardness testing

- Local grinding to determine crack depth

- Rough machining to remove cracks prior to heat treatment

- Annealing of crankpin journal to remove hardness

- Finish machining to 316mm ( – 4.00 mm undersize)

RESULTS

Goltens salvaged the crankshaft, within maker limits. Without the combined grinding and annealing process this crankshaft would have been condemned and required costly replacement

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now