Rapid response for rudder stock on-site machining

2-day job completion to keep yard period on track for bulk carrier

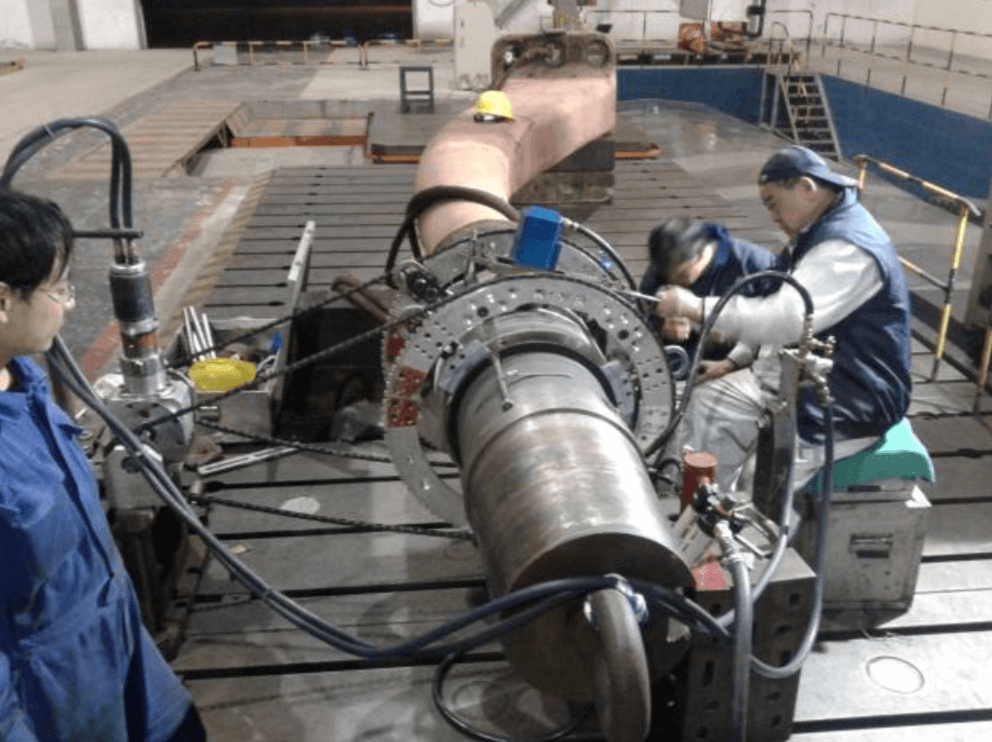

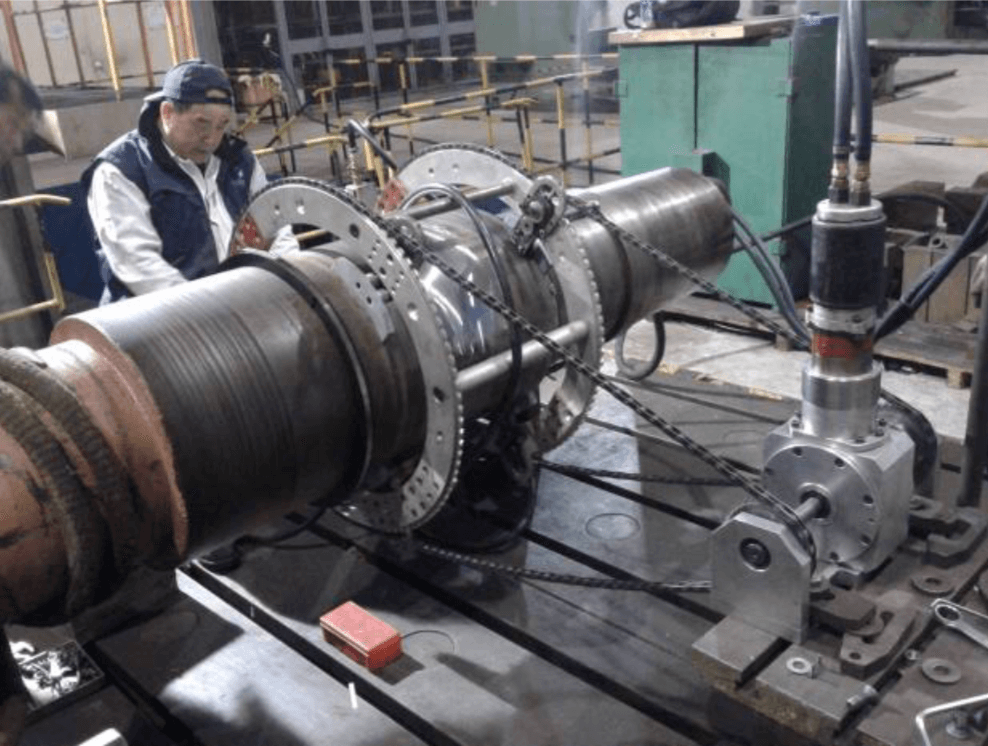

The 74,461 DWT bulk carrier Lilian Z was dry-docked at Chengxi Shipyard for completion of its 5-year survey. During the survey, wear and scraping was discovered on the rudder stock journal after the sleeve was removed. The attending superintendent was aware of Goltens’ in-situ machining capabilities and immediately approached Goltens for a solution.

Goltens immediately dispatched one of its on-site machining experts to inspect the rudder stock’s condition. Goltens determined that the repairs could be performed on-site avoiding the time and expense to transport the rudder stock to the workshop. Goltens proposal to repair the journal was reviewed and approved by the shipyard and the superintendent engineer and Goltens quickly got to work to keep the vessel on schedule.

PROJECT FACTS

| RUDDER STOCK REPAIR | |

|---|---|

| Vessel: | LILIAN Z |

| Vessel Type: | Bulk Carrier |

| Tonnage: | 74,461 DWT |

| Shaft Dimension: | OD: Ø500.00 × L: 450.00mm |

| Year Built: | 1999 |

RUDDER STOCK ON-SITE MACHINING REPAIRS

- Full cleaning of rudder stock journal

RUDDER STOCK REPAIR RESULTS

Goltens workshop perfectly completed this in-situ machining within 2 days and coordinate coordinated with the shipyard and Class society in order to meet the vessel’s tight schedule.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now