Crankshaft Annealing Salvages Damaged Crankshaft

Mitsubishi 18KU30B Repair In Rufisque, Senegal

Having previously performed in-situ machining at the plant in Rufisque in western Senegal, Goltens was already very familiar with the engines when Mitsubishi asked Goltens to inspect one of the nine Mitsubishi 18KU30B generators in operation there.

An inspection revealed that the 330mm crankpin journal had suffered a bearing failure resulting in hardness levels as high as 596 Brinell. Goltens proposed to Mitsubishi to anneal and machine the crankshaft to salvage the shaft within the rated diameter. But a shop trial awaited Goltens before it could begin annealing…

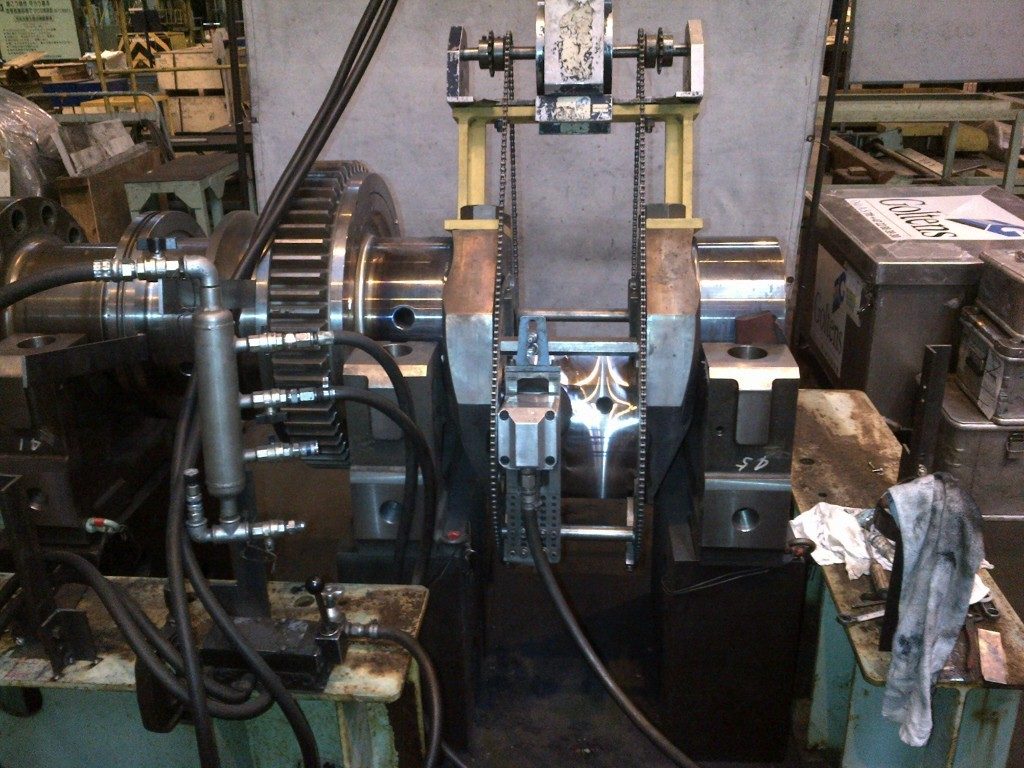

Demonstration of annealing process

Mitsubishi invited Goltens to demonstrate its annealing process on a crankshaft that had been intentionally hardened for the demonstration in its factory in Yokohama, Japan. Goltens technicians traveled to the factory and, following its GL-approved process, demonstrated the effectiveness of annealing to Mitsubishi.

After the successful shop trial, Goltens was engaged to anneal the damaged crankpin and mobilized its technicians, annealing equipment and in-situ crankshaft machining tools to Senegal to conduct the work. Goltens undertook all of the engine preparation required by its process to ensure the operation would not cause any damage to the engine casing from linear expansion of the crankshaft and machined the crankshaft surface free of cracks. The technicians then connected the annealing equipment and performed the heat treatment of the shaft.

PROJECT FACTS

| MITSUBISHI 18KU30B | |

|---|---|

| Location: | Rufisque, Senegal |

| Journal Diameter Pre-Machining: | 330mm |

| Final Journal Diameter: | 326mm |

| Max Hardness Pre-Annealing: | 596 HB |

IN-SITU ANNEALING RESULTS

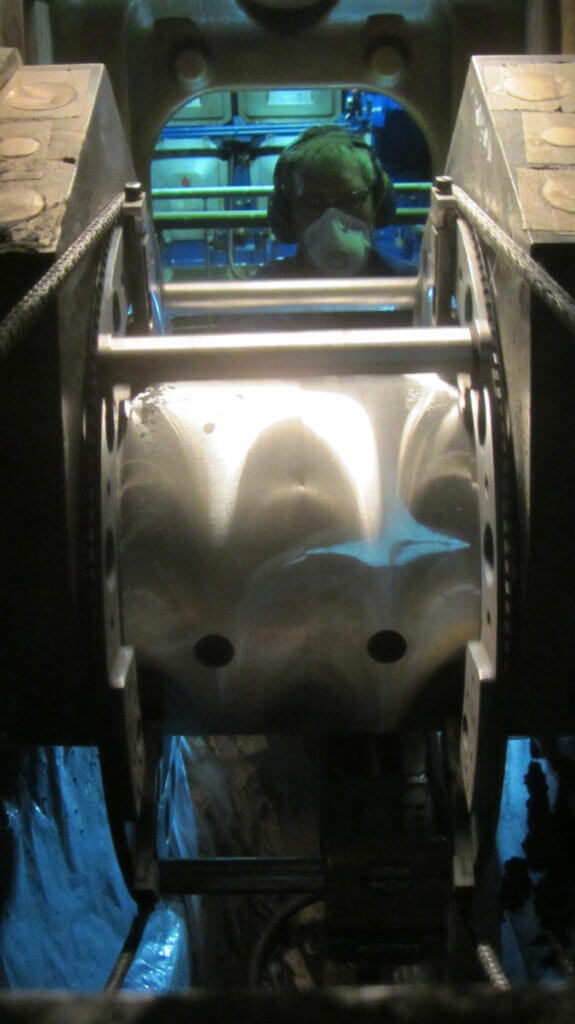

After annealing, Goltens took hardness readings and the hardness levels were dramatically reduced and accepted by Mitsubishi. The crankpin was then machined and polished to a finish diameter of 326mm removing only 4mm from the shaft diameter.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now