Wartsila 6L46C Crankshaft Annealing And Machining

Annealing Restores Badly Damaged Crankshaft

Goltens was contacted to inspect the damage to a Wartsila 6L46C crankshaft on an 8,937 DWT container vessel in Trinidad & Tobago. The vessel had suffered multiple bearing failures on crankpins #1 and #2.

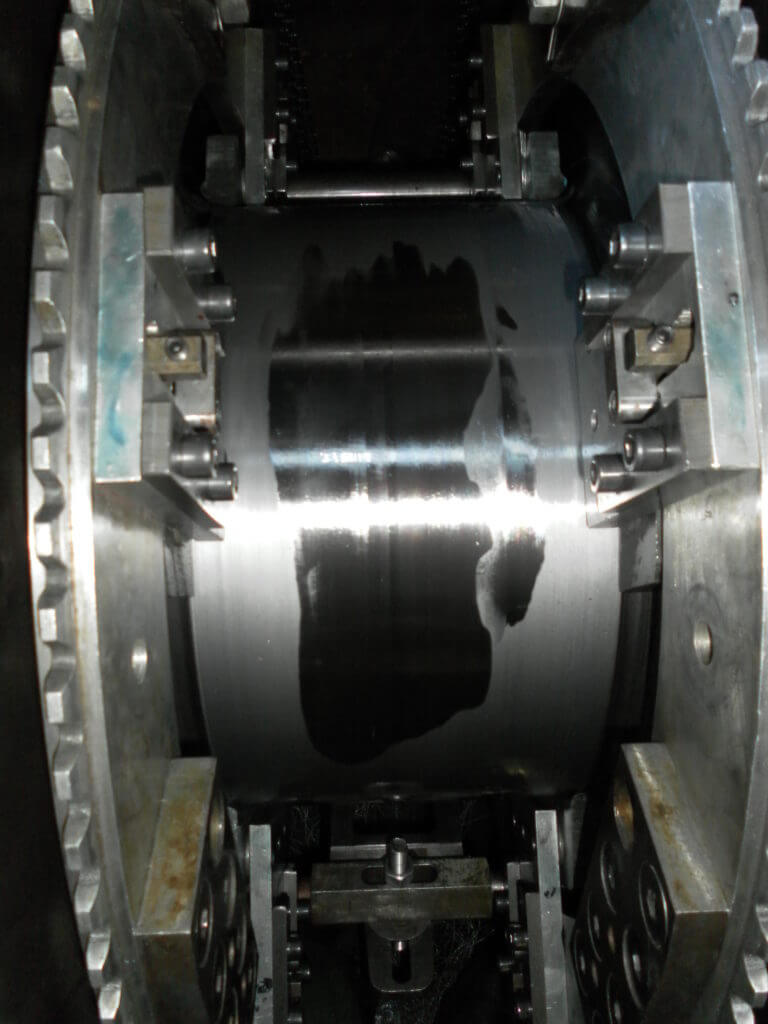

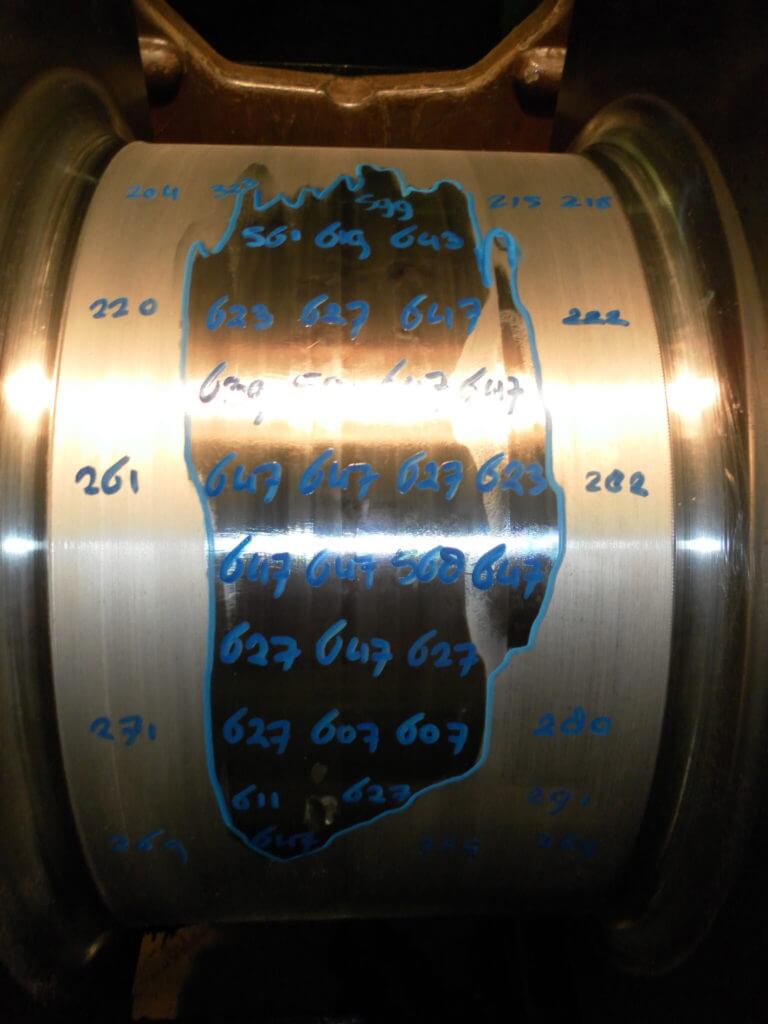

Goltens mobilized its in-situ machining tools to the vessel and began the evaluation of the crankshafts condition. Upon inspection of crankpin #1, it was evident that there were surface cracks and very high hardness levels 450HB-647HB on a 350mm long x 140mm wide area on the journal surface. Crankpin #2 was darkened from heat and had small surface cracks but the hardness was acceptable.

Due to the hardness values and the size of the hard spot, Goltens advised that it was unlikely that the hardness could be removed within the rated diameter for the crankshaft. A recommendation was made to the owner and to class surveyor, Lloyds Register, to mobilize Goltens’ annealing equipment and to reduce the hardness to acceptable levels via heat treatment and to finish machine it. Crankpin #2 would be locally ground and polished as the cracks were small.

PROJECT FACTS

| WARTSILA 6L46C CRANKSHAFT | |

|---|---|

| Crankpin #2 hardness pre/post: | 647HB/380HB |

| Original diameter Crankpin #2: | 450.00mm |

| 450.00mm | 447.00mm |

IN-SITU MACHINING REPAIRS

- Magnaflux and hardness checks on all crankpins

- Pre-annealing machining of crankpin #1 to 449.0mm to remove surface cracks

- Local grinding of cracks on #2 and finish polishing

- Annealing of crankpin #1

- Machining and polishing crankpin #1 to 447.00mm

- Inspection and measurement of crankpins 3-6

RESULTS

Goltens executed its class approved annealing process and reduced the hardness to acceptable levels on the crankshaft and salvaged the crankshaft at -3.00mm. The engine was restored to operation to the satisfaction of the owner and class.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now