Offshore Oil & Gas

Our highly qualified mobile teams routinely respond to planned maintenance as well as unplanned casualty conditions with the sole intention of restoring machinery to operation in a safe and professional manner, minimizing asset downtime for operators. Many of the world’s largest and most successful offshore operators rely on Goltens capabilities, response and precision delivery to keep their operations running uninterrupted.

Diesel/Dual Fuel Engine Service

Riding Crews – Goltens capabilities as an expert in comprehensive engine services are unquestioned. With 8 decades as an engine specialist, Goltens capabilities cover virtually all makes and models of larger bore 4 stroke and 2 stroke engines found in the marine market. Goltens engine service model is based on deploying highly trained teams or riding crews to effect the engine repair either alongside or on voyage to minimize the impact on schedules. Our teams travel will all tools required to overhaul components onboard negating the requirement to send components ashore.

Swing Set Model – To maximize efficiency and minimize downtime associated with overhauls, Goltens has implemented a “swing set” approach with certain operators. With this alternate approach to onboard overhaul, the owner secures an extra set of components that can be fully overhauled in Goltens’ workshop between overhauls and delivered onboard for the next scheduled maintenance. This limits onboard attendance, shortens overhaul/downtime periods and controls costs.

Major Casualties – Beyond routine maintenance, Goltens is known for its ability to restore engines from catastrophic casualties. Crankshaft, block and bedplate replacements are routine repair operations for Goltens and are done in the safest, most professional manner in the market. Through our global network of stations and suppliers, Goltens is very often able to offer fully inspected, class approved, reconditioned components at a significantly lower price than the cost of a new and usually faster than can be delivered from the OEM.

Workshop Reconditioning/Repairs

Goltens maintains fully equipped workshops with the capability to provide the fully class approved reconditioning and repair services required by the fleet. Capabilities include:

- Reconditioning of:

- Damaged crankshafts

- Fuel Injectors, nozzles, valves and pumps

- Piston Rods/Connecting Rods

- Exhaust valve spindles, seats and cages

- Cylinder liners

- Piston crowns/skirts

- Cylinder heads/covers

- Electrical motor rewinds and repairs

- Overhaul and repair of governors and controls

- Turbocharger repairs and balancing

- Centrifugal casting of white metal bearings/stern tubes

In-Place Machining

Goltens was the first company in the world to successfully complete the in-place machining of a marine crankshaft in the early 1950’s. Since then, Goltens has perfected its crankshaft machining tooling and expanded the range of machining services it provides to the world’s fleet. Examples of machining solutions provided include:

- In-place crankshaft machining (main and crankpin journal)

- In-place annealing of crankshafts (class approved)

- Line boring of engines

- Lower liner landing surface repair

- Broken cylinder stud removals

- Propeller shaft machining

- Flange facing

- Metal stitching / cast iron repair

- Laser alignment and chocking

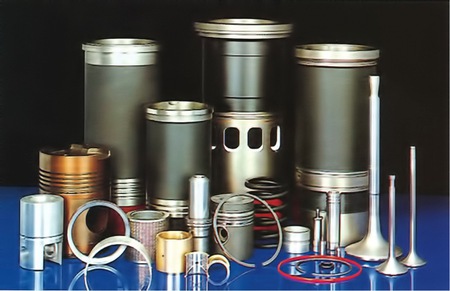

Spare Parts Supply

Goltens’ global network, scale of operations and principal relationships provide us significant access to both OEM and non-OEM diesel engine parts from hundreds of internationally renowned manufacturers.

We supply both new and reconditioned spares for main and auxiliary engines as well as a wide variety of ancillary equipment on the engine and across the engine room. Operators across the globe rely on Goltens for the supply of high quality, cost effective spares to support their operations.

Through our global network, Goltens can source a broad range of 2 Stroke and 4 Stroke parts for most major makers.

Case Studies

5 HiMSEN Overhauls Keep Diamond Offshore MODU Operational With Zero Downtime

Case StudyConversion of two platform supply vessels to well stimulation vessels in Dubai

Case StudyBergen Crankshaft Replacement on AHTS Offshore Supply Vessel

Case StudyIn-situ machining & laser flatness measurement for a FPSO conversion ship

Case Study7 engine overhaul keeps drill ship operational with no down time

Case StudyHyde Guardian BWT Retrofit Installation on a Vessel

Let Goltens Solve Your Challenge

Goltens is the right partner for ship owners and power plant operators all over the world. Response to all service enquiries typically falls within 12 hours.

Find Your Region’s Contact

Select a region below and find the right Goltens expert