Engine Laser Alignment and Chocking Compounds

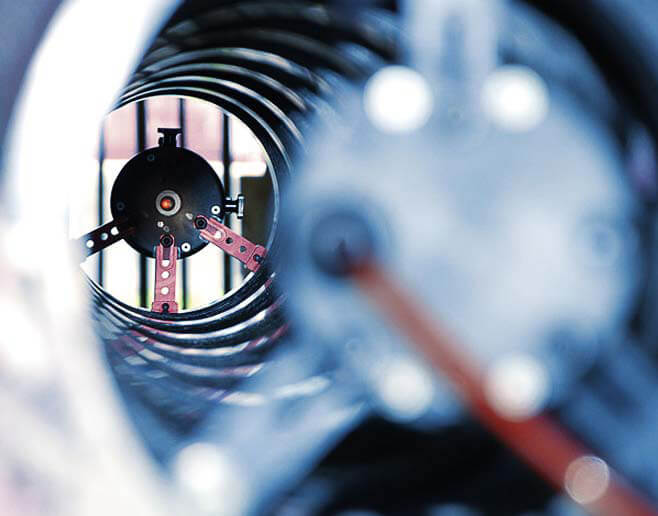

Goltens’ engine specialists and in-situ machinists have broad expertise using state-of-the-art laser alignment tools in engine applications.

To avoid uneccessary damage to your machinery, getting the proper alignment prior to operation is critical. In casualty situations, damage assessments and engine repairs, being able to accurately evaluate the condition of your engine is critical to getting the repair done right and to validating the accuracy of the repair.

We routinely perform laser alignment of main bearing and camshaft bearing pockets, shafts, generators and flatness checks on blocks and bedplates and other surfaces and any other equipment where straightness or flatness is critical. Checking the main bearing or camshaft bearing pocket alignments after a failure is critical to determining whether it is safe to rebuild your engine or whether additional in-place line boring is required.

Proper chocking is critical in new buildings and repairs to preserve the proper alignment of your engines and generators. Goltens stations around the globe have trained and certified technicians with vast experience designing alignment and chocking solutions for customers across all industries. Goltens supplies various types of epoxy grouting and repair solutions to suit the needs of Marine, Offshore and Industrial installations and offers chocking services globally using market leading products like ITW Polymer Technologies’ Chockfast® Pourable Chocking Compounds.

Let Goltens Solve Your Challenge

Goltens is the right partner for ship owners and power plant operators all over the world. Response to all service enquiries typically falls within 12 hours.

Find Your Region’s Contact

Select a region below and find the right Goltens expert