Two More Turnkey Techcross Bwts Retrofits By Goltens

SUCCESSFUL RETROFITS OF LNG CARRIERS LEADS TO ADDITIONAL RETROFITS AT MMHE SHIPYARD IN MALAYSIA

Having completed successful ballast water retrofitting of one of its LNG Carriers, Goltens Singapore was once again contracted by one of the world’s largest LNG owners and operators to complete similar turnkey retrofits on two 15- year-old, 83,000 DWT LNG carriers.

While Goltens is the global leader in ballast water retrofits having completed well over 850 retrofit projects, designing and executing the retrofit on such large vessels with one of the world’s largest ballast water systems presents a unique set of challenges.

DETAILED SCOPE OF WORK:

The scope was comprehensive and included completion of the following throughout the project lifecycle:

- 3D scanning & vessel survey

- Basic and detailed engineering

- Class approvals & Shipyard Management

- Procurement & Prefabrication

- Supply of material (big bore piping, small bore piping,site run piping & fittings, valves, actuators, cable & etc.)

- Installation and supervision in the yard

TECHNICAL DESCRIPTION (EACH SHIP):

| Vessel Length (LOA) | 288m |

| Vessel DWT | 83,000 Tons |

| Built Year & Yard | 2005 – DSME, Korea |

| BWTS | ECS-3,200 B x 2 Sets |

| Ballast Pump | 3,200 m3/h x 3 sets |

DESIGN & ENGINEERING PLANNING:

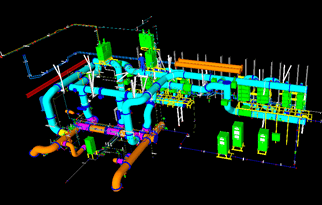

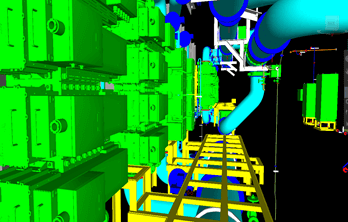

For each vessel, Goltens Singapore deployed a skilled team to perform 3D scanning and perform ship checks. The scans were then registered and Goltens began the baseline design with 3D modelling software. Once the baseline models were accepted, Goltens moved quickly to complete the full engineering design package for approval by the owners and class prior to procurement of materials & equipment for prefabrication.

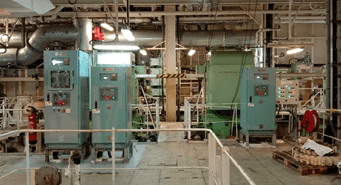

As was the case with the prior installation, the primary challenge for Goltens was space. The sheer size and number of the Techcross ballast pumps coupled with the limited area surrounding them was a design and planning challenge. The design team developed plans that optimized the space management and reviewed the designs thoroughly to ensure the machinery could be successfully installed and operated.

Quality management was also a primary focus during the prefabrication phase. Numerous quality and integrity inspections were completed by Goltens Engineers to ensure that the prefabricated pipe spools were satisfactory. As a final step, non-destructive testing was carried out by Goltens and witnessed by the owner’s representatives.

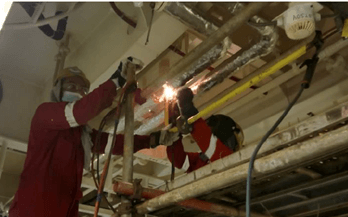

INSTALLATION PHASE:

The installation and commissioning of the systems were both completed at MMHE Shipyard in Johor, Malaysia. Goltens deployed a skilled workforce of 60 personnel including supervisors to ensure the installation was executed to the design and completed successfully despite short docking schedules.

Installation followed the same 5 stages established in the prior successful Techcross retrofit.

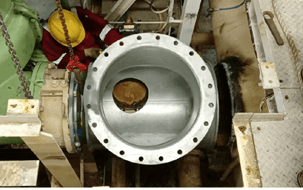

- Stage 1: Remove the existing pipes to install the tie in spools, lift out the existing pipes and install the newly fabricated big bore (600A) pipes.

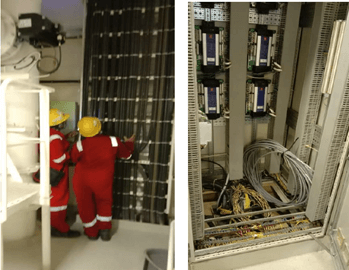

- Stage 2: Fabricate & install the foundation supports for the equipment (Electro Chamber Unit, Power Distribution Equipment, Auto Neutralization Unit & TRO Sensor Unit)

- Stage 3: Lifting the equipment safely into the lowest deck of the Engine Room and securing the equipment.

- Stage 4: Completion of electrical works including: cable pulling, cable termination at main switchboards, power distribution equipment and equipment onsite.

- Stage 5: Installation of the small-bore piping between the equipment and big-bore spools.

INSTALLATION PHASE:

Goltens worked closely with the owners and the shipyard throughout the process to drive progress and avoid any delays in completion. As a result, both installations were completed within the allotted time with one being executed in 18 days and the other in 20 days.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now