Simultaneous Machining of Crankpins Speeds Repair

GOLTENS’ MACHINISTS MACHINE 4 OF 5 DAMAGED CRANKPINS AT THE SAME TIME ON WARTSILA W6L32 ENGINE IN ONLY 8 DAYS

During periodic maintenance, the crew of a 14-year-old, 122,000 DWT container vessel, noted excessive wear and ovality on five of the six crankpins (#2 through #6) on one of their Wartsila W6L32 auxiliary generators. Crankpin #1 had previously been machined to undersize and did not require repair. The vessel owner contacted Goltens about undertaking the further inspection and rectification of the worn crankpins.

Due to vessel’s schedule and challenges introduced by COVID travel restrictions, Goltens proposed deploying a 3- man machining team to undertake multiple crankpins at the same time. Under normal circumstances, machining 5 crankpins would have required 14 days, but Goltens proposal would get the job done in only 8 days on voyage between Newark and Miami.

THE REPAIR

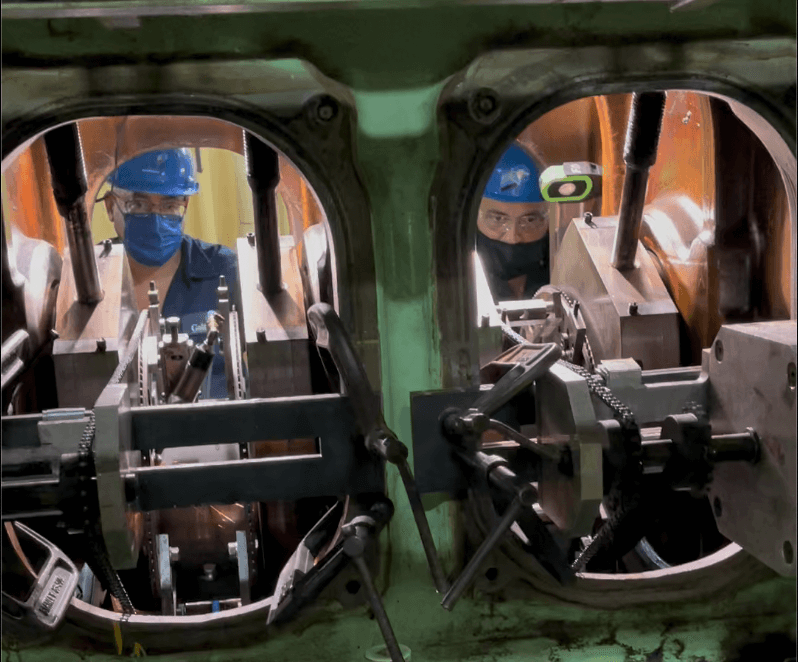

Goltens mobilized the team and two sets of tooling to Newark, NJ to meet the vessel. Onboard measurements confirmed that crankpins #2 and #6 were at their maximum wear limits and the others showed ovality. The owner decided to proceed with machining of crankpins #2 to #6 to the next undersize diameter at (0.5mm). Goltens installed two sets of machining tooling on crankpins #2 and #5 and completed machining before moving the machines to crankpins #3 and #4. Crankpin #6 was machined alone to complete the repair work.

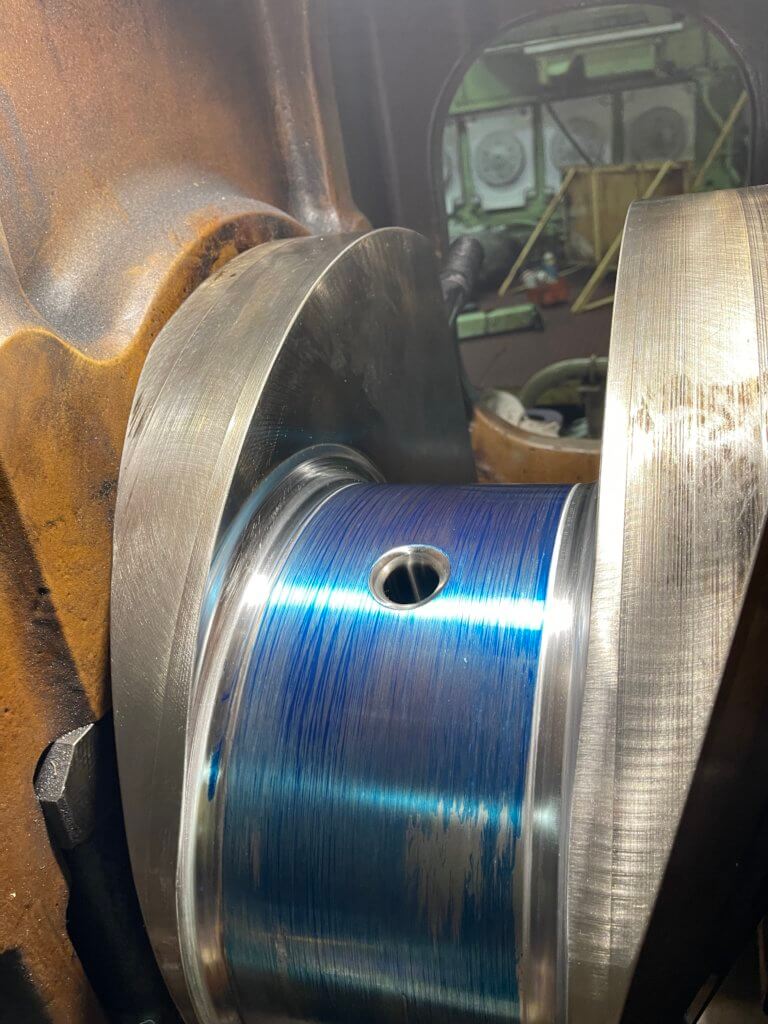

After removal of the (0.5mm) from the five crankpins, all crankpins were machine polished and contact surfaces were verified by use of a bluing dummy. Final surface finish showed roughness values of between 0.27 and 0.30 Ra.

RESULTS

Goltens completed the work within the 8-day voyage and the team turned the engine back over to the ship’s capable engineering crew for full flushing of the engine and rebuild with new bearings prior to operational testing.

The compressed schedule minimized the engine’s downtime and avoided challenging travel logistics induced by COVID.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now