In-Situ Laser Cladding and Machining Restores Chinese Chemical Plant to Operation

LARGE MULTI-AXIS COMPRESSOR SLIDE BEARING HOUSING REPAIR IN ONLY 4 DAYS

A Chinese PTA chemical plant, with 1.5 million tons of annual production, was undergoing an emergency overhaul on a large multi-axis air compressor critical to plant production. Due to the criticality of the compressor, the plant was pressing for the shortest possible completion.

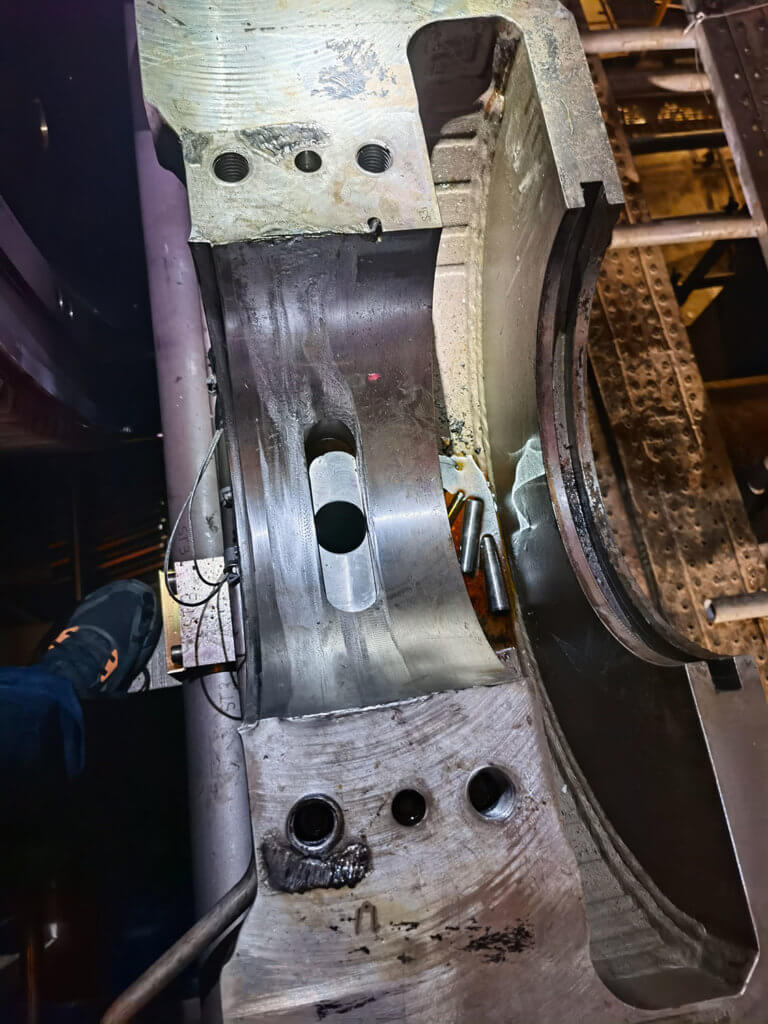

Unfortunately, when the compressor was disassembled, the main bearing was found severely damaged due to overheating. The compressor OEM immediately contacted Goltens for a solution that would repair the bearing housing and return it to original dimensions. Understanding the urgency, Goltens deployed an In-Situ specialist and, after inspection, advised the OEM and plant the housing could be repaired on-site with laser cladding and machining.

Goltens deployed two teams to work around the clock to complete the repair as soon as possible.

REPAIR DETAILS

- On-site inspection & technical evaluation/proposal

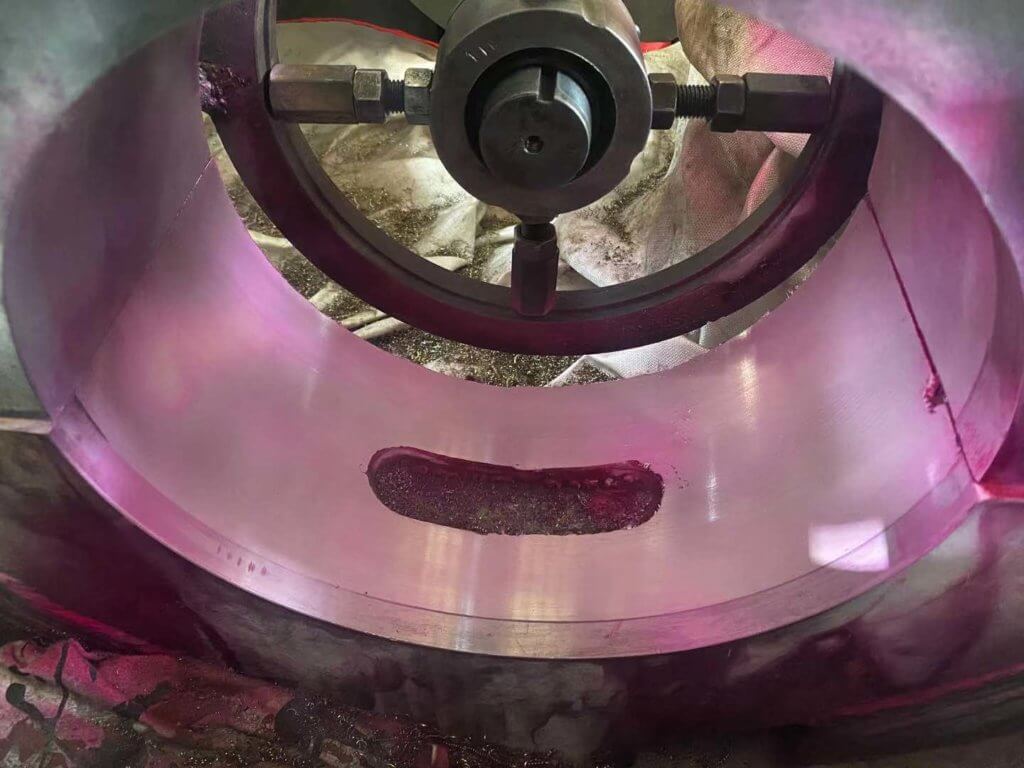

- Cleaning, calibration and penetrant dye check of housing

- In-situ machining of damaged housing surface

- In-situ laser cladding of bearing housing

- In-situ line boring to standard dimension of 280mm +/-0.02-0.03mm

- Hardness & roughness measurement

THREE DAYS AHEAD OF SCHEDULE

The job was planned to be completed in 7 days but, with two shifts of specialists and the proper tooling, Goltens’ completed the task 3 days ahead of schedule.

The plant then completed reassembly of the compressor and performed operational load tests finding all performance data within required parameters.

Another specialized job completed with a focus on minimizing asset downtime for our customer.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now