30-Ton Bergen Crankshaft Replacement for Russian Powerplant

9 DAYS IN ARKHANGELSK

A powerplant in Arkhangelsk, Russia that supplies power to a local diamond mine suffered a casualty on one of its Bergen B32:40V12 engines. The extent of the damage was such that the crankshaft could not be saved by machining and required replacement.

As the plant’s overhead crane capacity was insufficient to lift the 30-ton block, Goltens’ technical management needed to prepare for the crankshaft exchange in a different manner than the norm. After evaluating the plant layout, Goltens proposed prefabrication of tooling and braces for lifting and securing the block safely to allow for the crankshaft to be removed.

LIFTING OPERATIONS

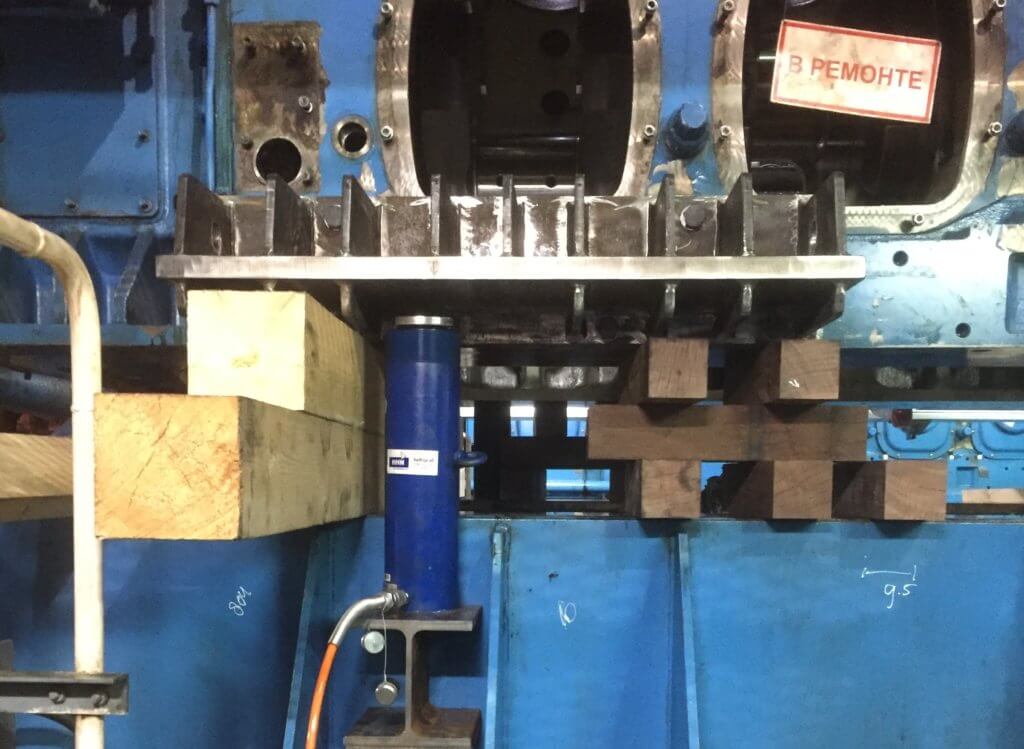

Goltens’ diesel team arrived onsite with the most of the engine already disassembled by the powerhouse team. The team removed some remaining components from the engine, removed the foundation bolts from the engine and fit the 4 prefabricated frame brackets to the block and began lifting operations with hydraulic jacks.

Goltens lifted the block in stages inserting wooden blocks underneath to support the block during lifting operations. Once the block was lifted to a height of 135cm, prefabricated, steel vertical supports were installed to secure all in place during the crankshaft removal.

CRANKSHAFT REMOVAL

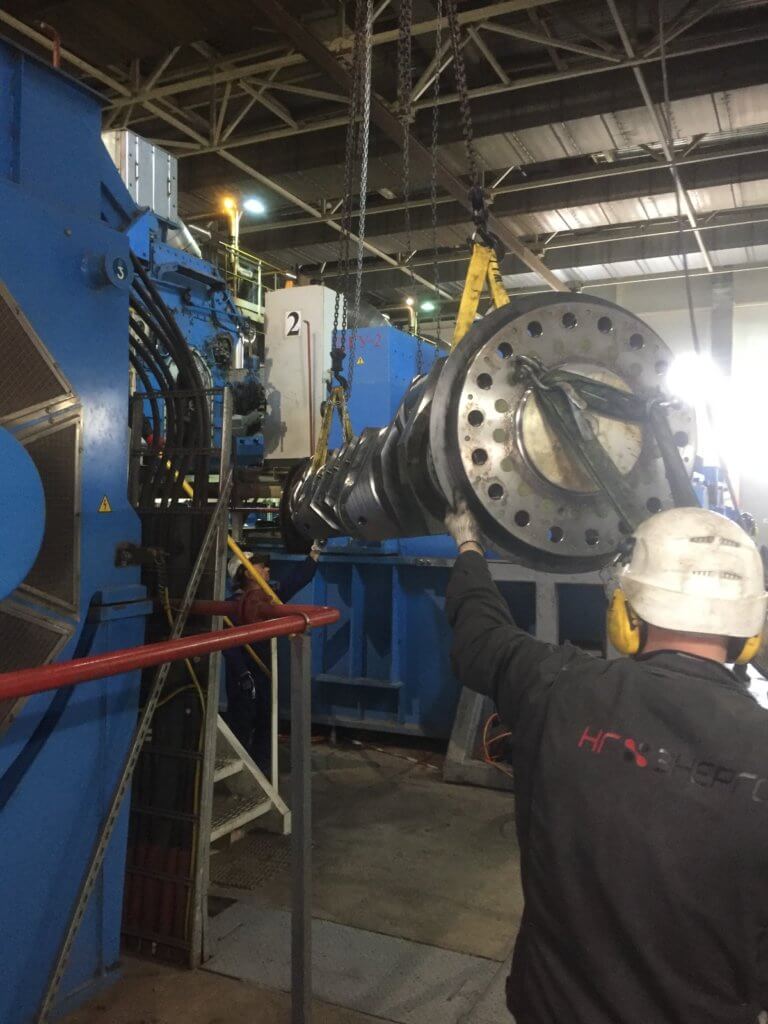

With the block lifted and secured, the counterweights were removed and plant personnel removed the vibration dampener. With chain blocks and lifting slings fitted on the crankshaft, the main bearing caps were removed and the crankshaft was carefully lowered and maneuvered out from under the block.

Bearing caps were then reinstalled and all bearing pockets were calibrated at 6 points before carrying out a laser alignment check on the main journal bores. All readings were accepted by the client and the OEM.

CRANKSHAFT REPLACEMENT

With the bearing caps removed again, the new crankshaft was inspected and all journals protected for the lifting operation. The crankshaft was then carefully moved by crane to the end of the engine where the crankshaft was gradually moved underneath the block and lifted into position.

All main bearing caps were then reinstalled with new bearings, side bolts tightened and counterweights reinstalled on the crankshaft.

Now, following the reverse of the lifting procedure, the block was lowered back onto the bedplate with a new gasket and foundation bolts were tightened.

JOB COMPLETED ON TIME

The job was completed inside the 9-day window provided for the work. With the crankshaft successfully exchanged, Goltens’ team packed its tools and returned to Rotterdam leaving the rest of the rebuild to the plant.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now