BioWAVE™ in-situ machining

Goltens Helps Strategic Marine Manufacture Structure For Wave Powered Electrical Generation Plant

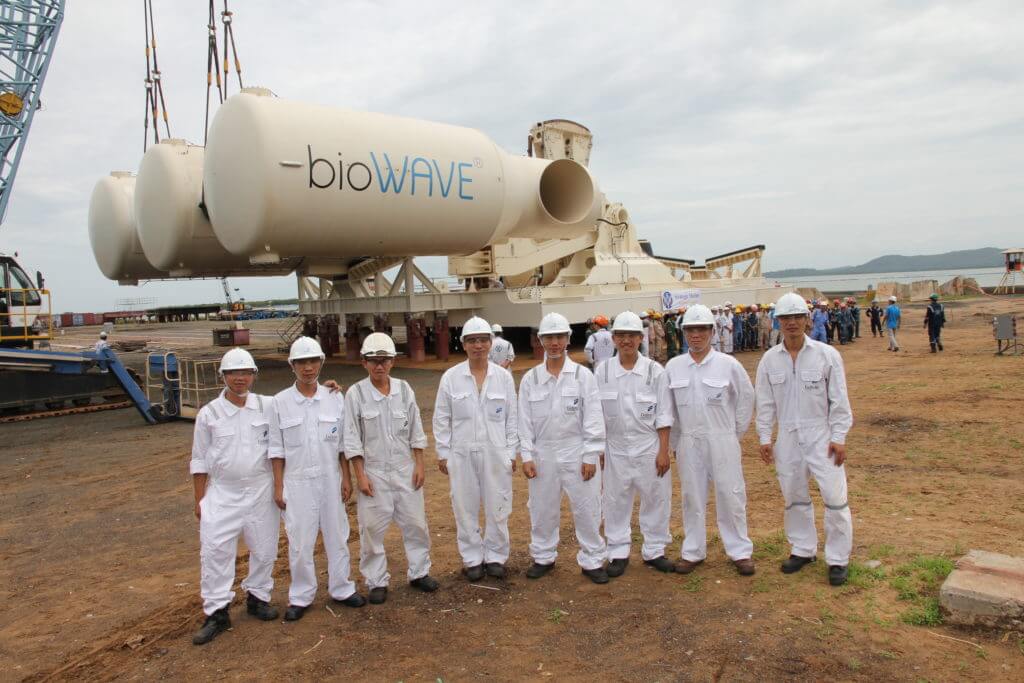

Goltens was called on by STRATEGIC MARINE in Vung Tau, Vietnam to assist in the manufacturing of a bioWAVE™ system. Goltens’ in-situ and workshop machining expertise was needed to carry out line boring, facing and milling on unique elements of the structure.

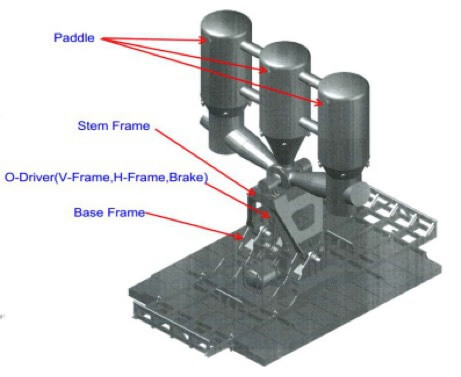

THE BIOWAVE™:

The bioWAVE™ ( http://www.biopowersystems.com/ ) is being developed for utility-scale power production from ocean waves. Its nature-inspired design (biomimicry) combines high conversion efficiency with the ability to avoid excessive wave forces, enabling supply of grid-connected electricity at a competitive price per MWh.

The bioWAVE™ is mounted on the seafloor, with a pivot near the bottom. The array of buoyant floats, or “blades”, interacts with the rising and falling sea surface (potential energy) and the sub-surface back-and-forth water movement (kinetic energy). As a result, the pivoting structure sways back-and- forth in tune with the waves, and the energy contained in this motion is converted to electricity by an onboard self-contained power conversion module, called O-Drive™ . The O-Drive™ contains a hydraulic system that converts the mechanical energy from this motion into fluid pressure, which is used to spin a generator. Power is then delivered to shore by a subsea cable. The result – efficient, clean energy from the ocean.

PROJECT FACTS

| bioWAVETM System Machining | |

|---|---|

| Location: | Vung Tau, Vietnam |

| Customer: | Strategic Marine |

| Frame Holes: | 4 (four) |

| Frame Hole Dimensions: | ID1000 x 230mmL |

| Stem Frame Connections: | 4 (four) |

| Connection Dimensions: | 2420mm x 1000mm (2 each) 2900mm x 1450mm (2 each) |

IN-PLACE MACHINING SCOPE

- Stem Frame Machining using 3000mm x 3000 mm X-Y Milling machine

- Machined 2 facing connections to the bearing cover measuring 2420mm x 1000mm

- Machine 2 facing connection to the hub measuring 2900mm x 1450mm

- Line Boring of and thrust bearing facing of four base frame holes using G-1000 Portable Line Boring machine

- Frame hole dimension: ID1000 x 230mmL

- Thrust bearing face dimension: OD1300mm x 140mmW

WORKSHOP MACHINING SCOPE

- V-FRAME Machining using vertical CNC machine

- BRAKE FRAME Machining using vertical CNC machine

IN-SITU AND WORKSHOP MACHINING RESULTS

After Goltens’ specialists completed the machining, Strategic Marine’s quality control personnel and the Owner checked the results. All were satisfied with the methods utilized by Goltens and the quality of the results.