A Complete In-Situ Diesel Engine Repair

Wartsila SWD 280 journal grinding, annealing, laser alignment, line boring and engine rebuild

Goltens was presented with a challenging opportunity in Honduras. The customer’s engine had incurred significant damage to the crankshaft and block. Goltens’ technicians performed an evaluation of the shaft and engine and found that the crankshaft was damaged on one Main journal and one Crankpin journal and hardness tests showed areas in both journals around 600 Brinell.

In order to save the shaft, it would need to be annealed. Additionally, the main journal pocket was damaged by the main journal bearing failure and had to be line bored and so the crankshaft was removed from the engine.

Due to the remote location of the plant, the customer did not want to incur the costs of shipping the shaft overseas to be reconditioned in the workshop and requested that Goltens perform all repairs on site.

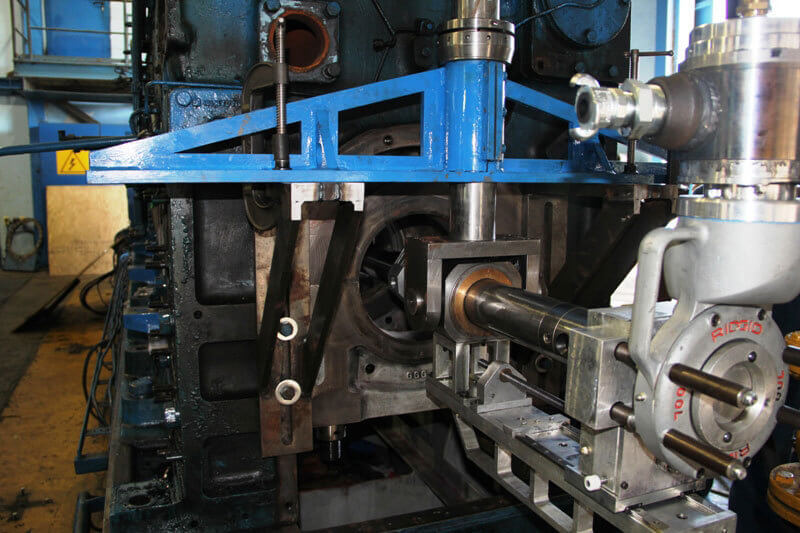

Goltens mobilized Diesel technicians and tools to disassemble the engine and remove the crankshaft. Simultaneously Goltens mobilized in-situ line boring , crankshaft grinding, annealing equipment and technicians to site. Goltens ground all journal surface cracks out prior to annealing the crankshaft which reduced hardness to acceptable levels below 375 Brinell. While the shaft was being annealed, the crankcase and frame were mounted back again and a laser alignment and line boring was completed with all main bearing cap landing surfaces machined in order to keep the original main journal bore diameter.

After the line boring the shaft was placed back in the engine again. Engine was built up again and test run performed by Goltens technicians.

DIESEL ENGINE PROJECT FACTS

| SWD 8SW280 | |

|---|---|

| Original Crankpin Diameter: | 220.00 mm |

| Finished Crank pin Diameter: | 217.00 mm |

| Main Journal Diameter: | 220.00 mm |

| Finished Main Journal Diameter: | 218.00 mm |

| Pre-Annealing Hardness (Max): | 600 Brinell |

| Post Annealing Hardness (Max): | 375 Brinell |

DIESEL ENGINE REPAIRS

- Diameter measurement, Magnaflux and Hardness testing of crankshaft

- Grinding of Main and Crankpin journal until free of cracks

- Disassembly of engine and removal of crankshaft

- Annealing of both journals to remove excessive hardness

- Laser bore alignment check of all main journal bores

- Machining all lower bearing caps

- Line Boring of all main bearing pockets to standard size

- Reinstallation of crankshaft and reassembly of the engine block

- Finish grinding of the crankshaft to 2.00mm and 3.00mm undersize for main and crankpin journals respectively

- Reassembly of all engine components, completion of pre-start checks and operational run in of the engine

GOLTEN REPAIR RESULTS

Goltens’ technicians completed the entire engine repair on- site using its full capabilities as specialist engine repair engineers and In-Situ machining specialists. The engine was restored to full operation and the customer avoided the cost of transporting the damaged components to a remote workshop for repair.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now