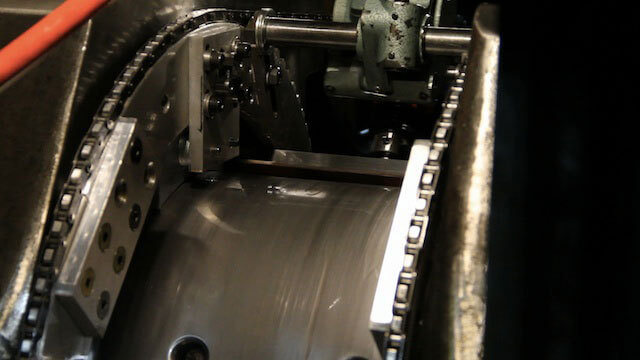

Crankshaft journal machining

Pielstick 18PC4.2V engine

A power plant in the Caribbean suffered a series of casualties on two of its 18PC4.2V diesel generators. The first casualty resulted from a bearing failure on crankpin number 6 while the second engine’s casualty was caused by an engine overspeed resulting in damage to crankpin number 8. Due to the owner’s disciplined maintenance, the engines’ monitoring and control systems were functioning well and kept the casualties from doing major damage to either engine.

Goltens was engaged to perform an inspection of the crankshafts to evaluate damage and perform repairs if necessary. The engine with the bearing failure was found to have normal hardness and some minor surface damage that would require machining while the engine that oversped was found to have minor damage that could be corrected with machine polishing.

Goltens mobilized its technicians and single point journal cutting tools to the island and executed the repairs on both engines.

PROJECT FACTS

| PIELSTICK 18PC4.2V | |

|---|---|

| Engine Output: | 21,517KW |

| Crankpin Length: | 342.00mm |

| Original Crankpin Diameter: | >465.00mm |

| Finished Crankpin Diameter: | 464.50mm |

REPAIRS

- Magnaflux and Hardness checks on crankshafts

- Run out and ovality checks

- Machining of 0.5 mm off Crankpin #6

- Machine polishing of Crankpin #6 and #8 to a finish of 0.2Ra

- Finish grinding of fillet radii on Crankpin #6

RESULTS

Goltens’ In-Situ team was able to complete the machining efforts in under a week’s machining time restoring both damaged engines to full operation.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now