Creative chockfast orange solution avoids costly machining work

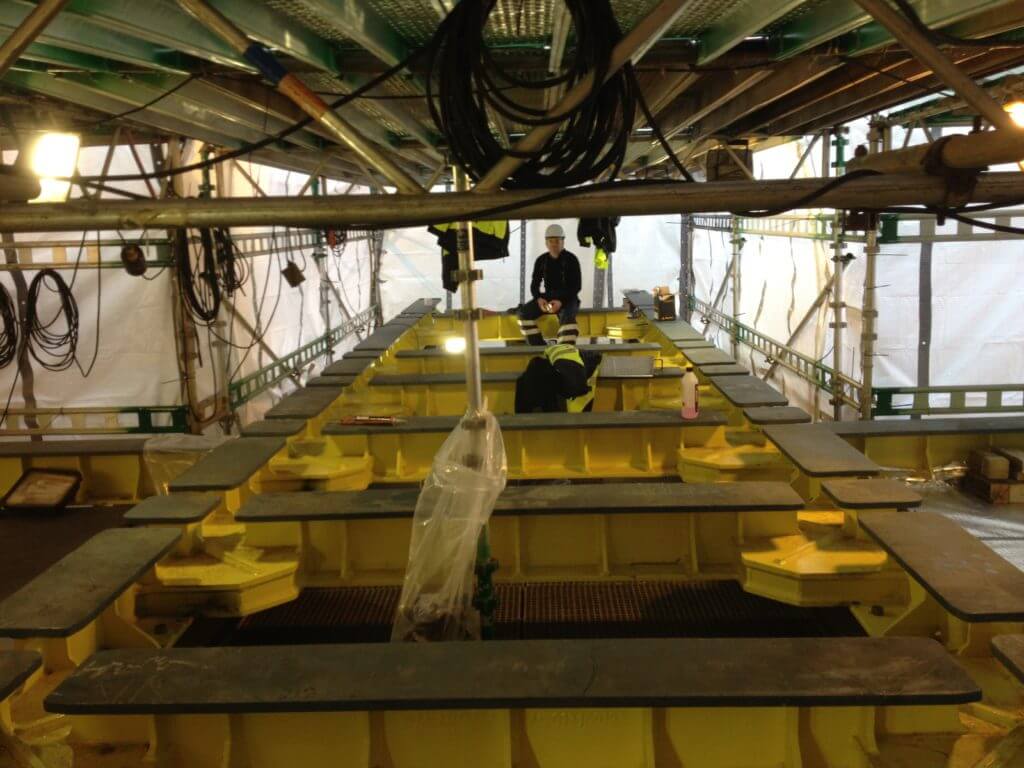

13,000mm x 400mm skid foundation onboard Norwegian jack up oil rig

Goltens was contacted by a shipyard to evaluate a challenge onboard a Jack Up Drilling Rig undergoing a refit on the West Coast of Norway.

The customer required a foundation for a skid foundation for a crane that could withstand a total load of more than 100 tons. Upon evaluation, Goltens determined that the foundation could be machined but that there was a much more efficient solution to the problem that would take significantly less time to complete.

As the long time distributor for ITW Polymer Technologies’ Chockfast product , Goltens saw an opportunity to avoid a costly in-situ machining project. After performing the calculations and engineering the alternative solution, Goltens determined that the Chockfast foundation could more than support the tonnage requirements of the skid.

Goltens presented the alternative solution to the customer and Goltens was given the order to proceed.

PROJECT FACTS

| OIL RIG SKID CHOCKFASTING | |

|---|---|

| Length of Foundation: | 13,000mm |

| Width of Foundation: | 400mm |

| Thickness of Foundation: | 20-25mm |

| Liters of Chockfast Orange used: | 350 Liters |

SKID FOUNDATION WORK SCOPE

- Engineering/Design of Chockfast Orange foundation

- Fabrication of Plastazote molds for the Chocking material

- Pouring of 350 liters of Chockfast Orange compound to support the 13,000mm x 400mm H Beam foundation of skid.

RESULTS

The total job was completed by Goltens in only 3 days. Inspection of the foundation by the customer was satisfactory and Goltens expects follow on orders for the execution of similar work for additional skid foundations.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now