Emergency Repairs Restore LPG Carrier’s B&W 6S50MC Main Engine In Houston

Fast, Precision Response Restores LPG Carrier To Operation

During transit from Africa to Houston, an 18,699DWT LPG carrier experienced fluctuating exhaust temperatures and pulsation on the charge air on their Hitachi Zosen B&W 6S50MC main engine.

Upon arrival into the Port of Houston a visual inspection confirmed all but one of the pistons contained multiple broken and seized piston rings. Goltens Houston was contracted and mobilized a service team to start work as soon as the cargo was discharged.

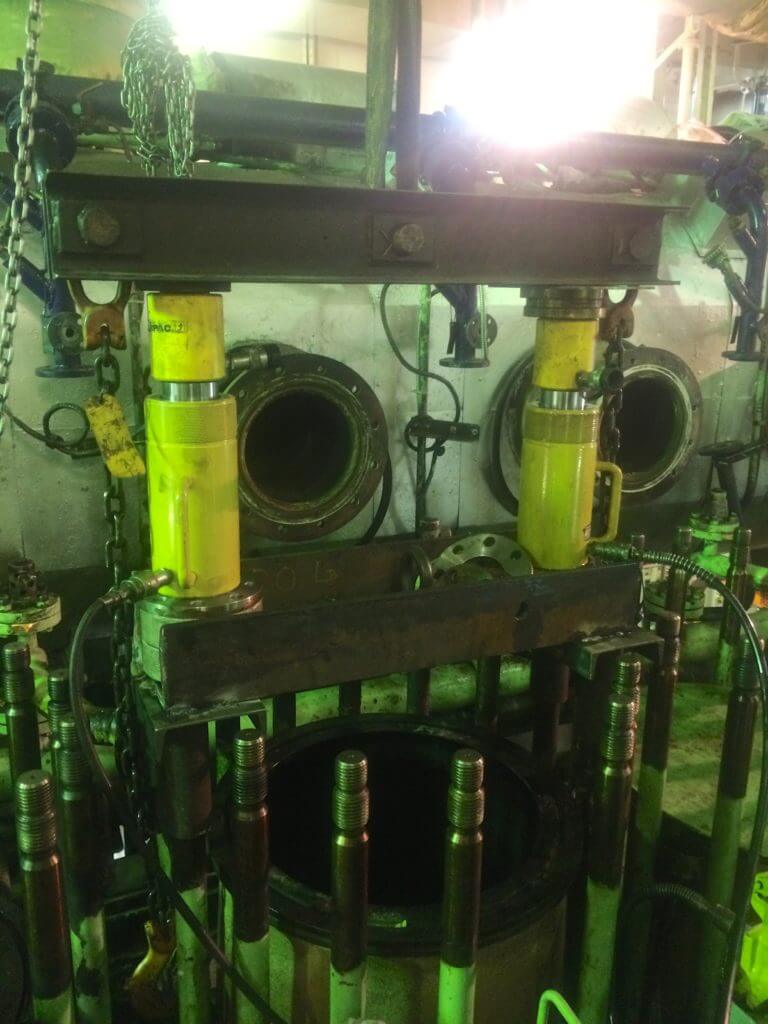

A comprehensive service plan was developed with the vessel’s technical management team to perform the work pier side in the Port of Houston. The aggressive repair schedule was initially challenged when the first liners pulled were seized due to sediment build up in the area of the lower block landing surface. Goltens mobilized additional tooling, strong backs and jacks to facilitate the removal of the seized liners. At the request of the vessel, additional service engineers were dispatched and a second shift was run until the schedule was again on track.

Shore side workshop and machining services proved to be vital as all six piston rods were removed and taken to the Houston Service Center for machining. Additional machining was required to manufacture spare piston rod spacer plates to replace the missing in-service component and provide the vessel with an onboard spare.

PROJECT FACTS

| LPG CARRIER MAIN ENGINE | |

|---|---|

| Work Location: | Houston, Texas |

| Engine Make/Model: | Hitachi Zosen B&W 6S50MC |

| Engine Output: | 6845Kw at 115RPM |

B&W 6S59MC MAIN ENGINE REPAIR SCOPE

- Inspection and overhaul of all six liner and piston assemblies

- Inspection cleaning and overhaul of all cylinder covers

- Machining of piston rod landing surface to renew contact surfaces

- Rebuild and overhaul of all fuel injection equipment

- Reassembly of engine, calibration run and break in of piston rings according to manufacturer specification

B&W 6S50MC REPAIR RESULT

In addition to completing the original work scope, Goltens Houston also addressed the additional challenges presented by the repair including stuck liners, piston rod machining and spacer plate manufacturing. The entire project was completed according to the original schedule to the satisfaction of the vessel’s Fleet Superintendent and Chief Engineer.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now