Metal stitching repair salvages badly damaged MaK 12M282 engine block

Connecting rod failure on offshore supply vessel’s MaK 12M282 generator

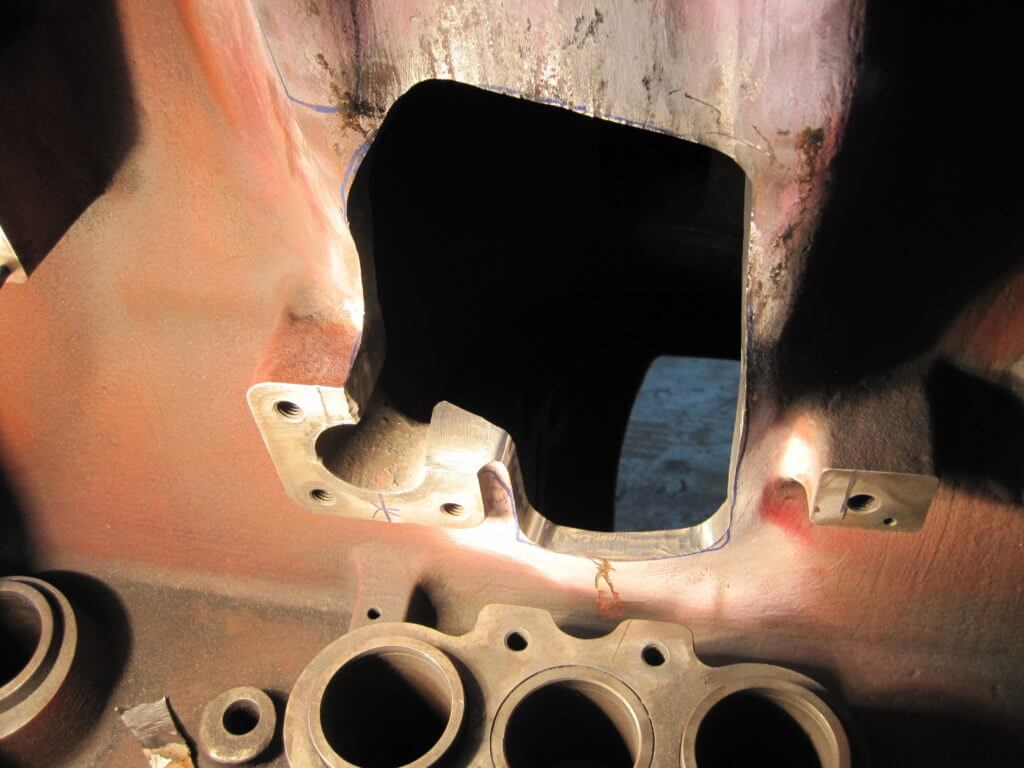

A highly specialized offshore vessel in the US Gulf suffered a catastrophic failure on one of its MaK 12M282 generators. The connecting rod broke away from the crankshaft and broke through the block of the engine.

Goltens had been supporting this customer for years in the repair and maintenance of these engines and after inspection, was able to propose a repair to salvage the badly damaged block by metal stitching . Additionally, Goltens proposed to rebuild the entire engine in its workshop and install it onboard the offshore vessel when completed.

The repair was made easier by the fact that Goltens had access to a condemned block of the same model that it could cannibalize for replacement pieces to stitch into place.

PROJECT FACTS

| METAL STITCHING | |

|---|---|

| Engine Model: | MaK 12M282 |

| Vessel Type: | FPSO |

| Engine Output: | 2,400KW |

| RPM: | 1,000 RPM |

METAL STITCHING REPAIR

- Full inspection of the damaged block

- Removal of damaged portions of the block – leaving a clean surface to stitch replacement pieces to.

- Cutting and fitting replacement pieces from condemned block to stitch into place

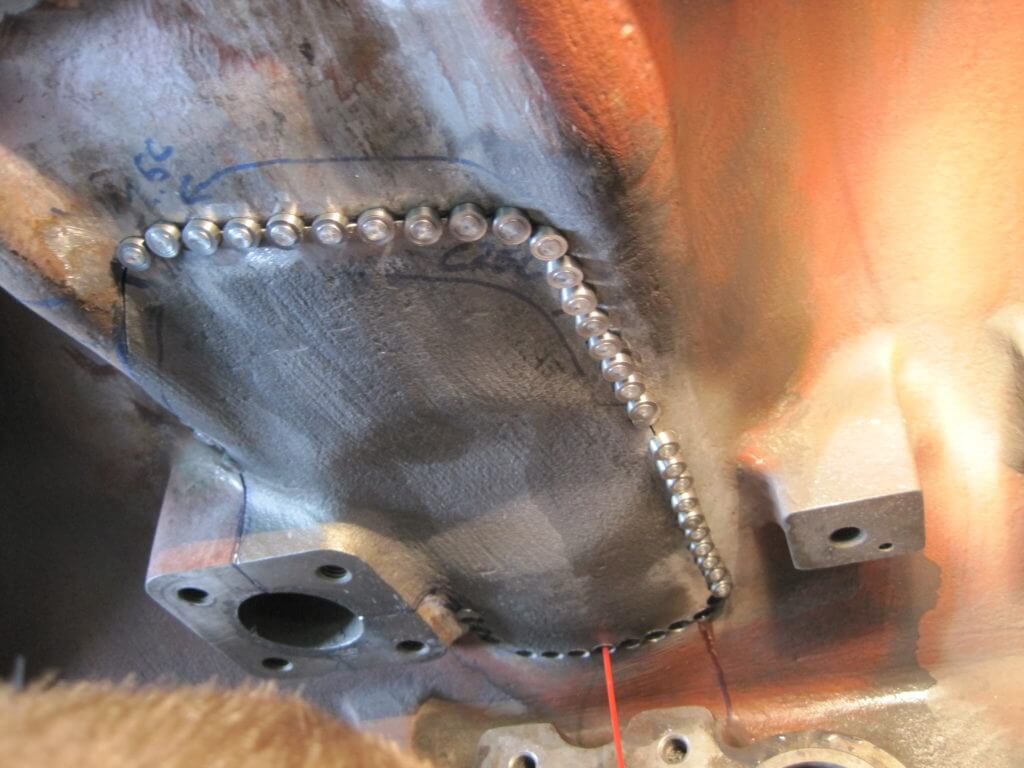

- Metal stitching replacement pieces into place

- Drilling of holes using the lock jigs and insertion of the locks

- Finish machining and stress relieving of seam surfaces

- Crack testing of the metal stitched seams to ensure repair is 100% effective

METAL STITCHING RESULTS

The repair was reviewed and accepted by class and the engine was ready to be rebuilt and put back into service on the vessel. Goltens’ metal stitching repair avoided a costly purchase of a replacement block and enabled the owner to repair the engine in a much more cost effective manner.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now