High-precision In-place Machining on Stern Tube Housing

GREG MORTIMER – CHINA’S FIRST EXPEDITION CRUISE SHIP NEW BUILDING

Goltens customer CMHI Jiangsu has secured an order of 4 plus 6 options for expedition cruise vessel new buildings. These are the first ice class expedition vessels to be built in China. Based on the Ulstein X Bow design, the first vessel was delivered in 2019.

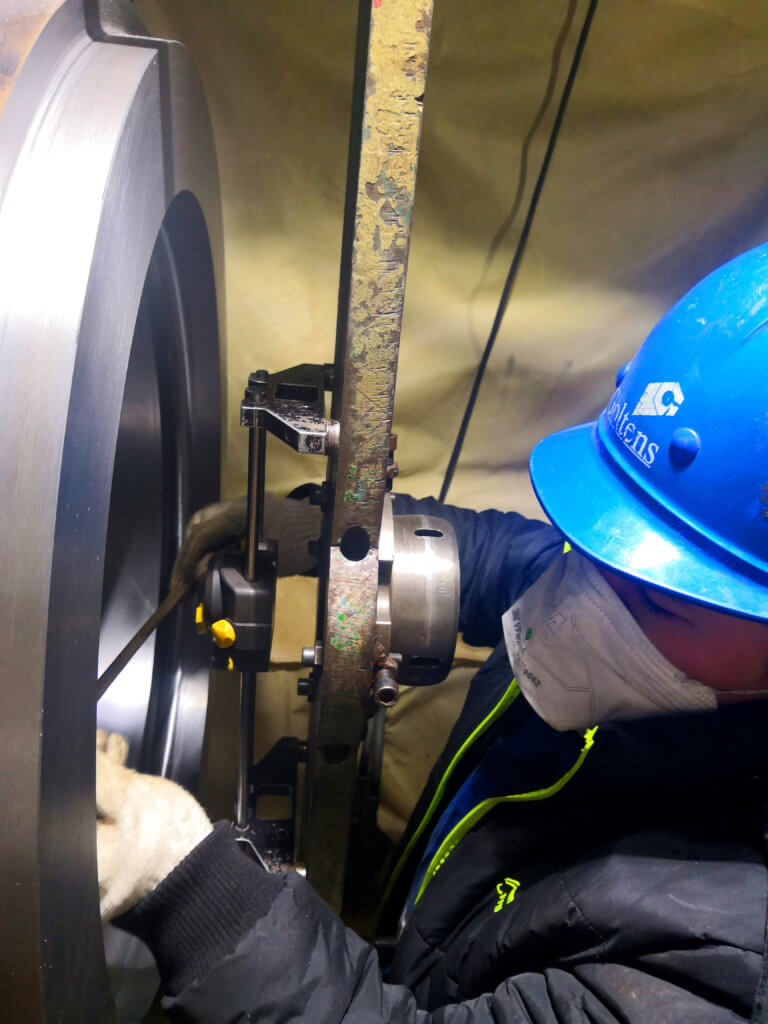

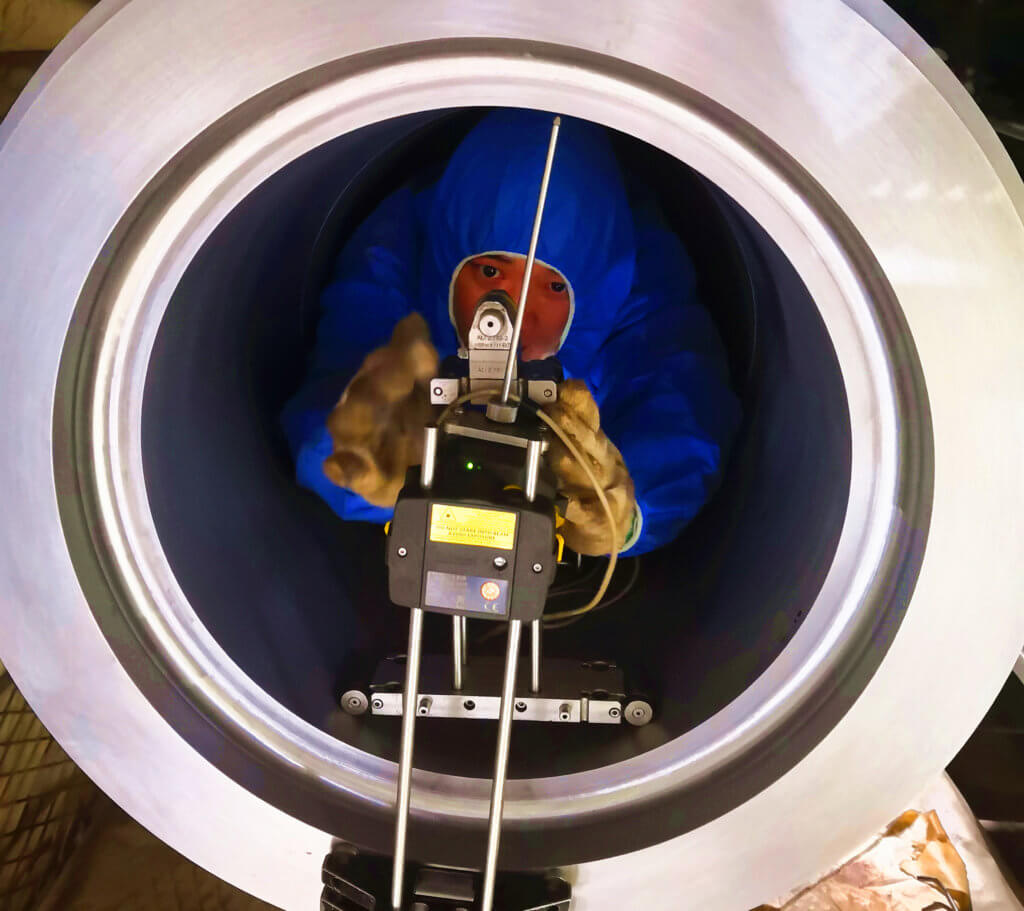

The stern tube design for Greg Mortimer required very high tolerances and as such the accuracy of the machining and alignment of the stern tubes was critical. CMHI Jiangsu did not have the capability for such high tolerance work so a specialist in-place machining and laser alignment team from Goltens was engaged to complete the work.

After preliminary meetings and discussions on the tolerances of the bush and tube Goltens proposed a combination of on-site and workshop efforts to complete the work.

ON-SITE WORKSCOPE

- Port and Stbd. Bore alignment laser checks

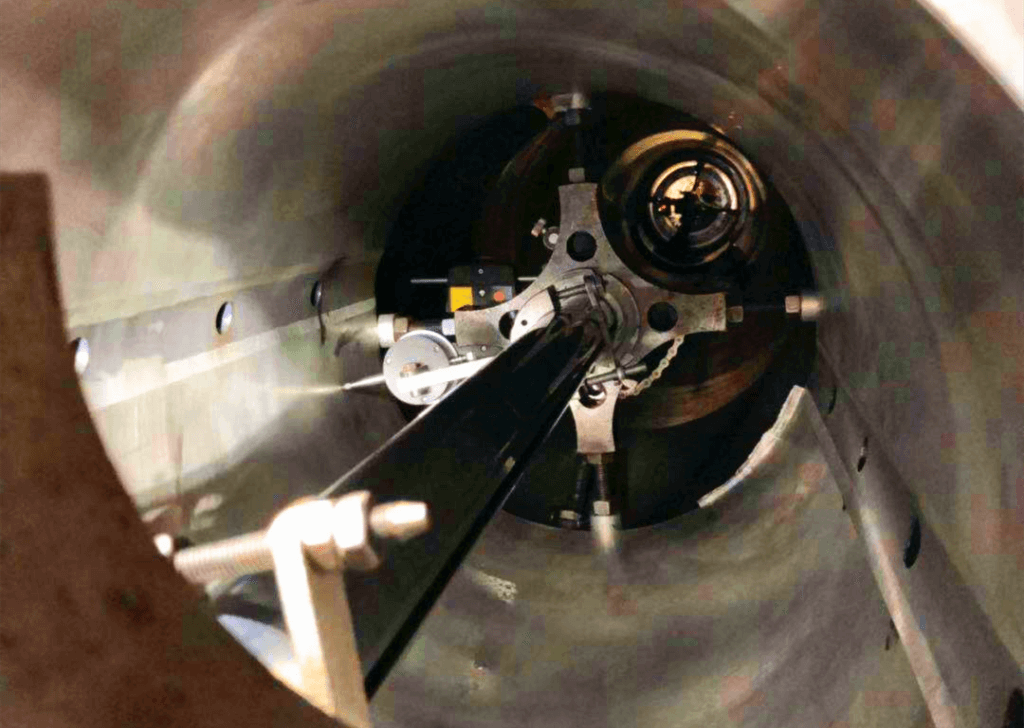

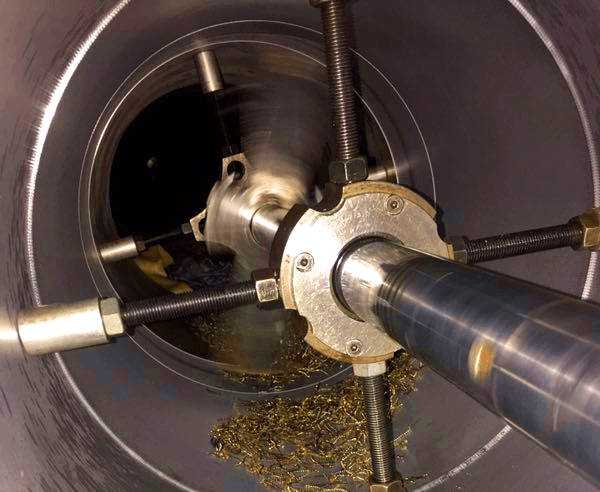

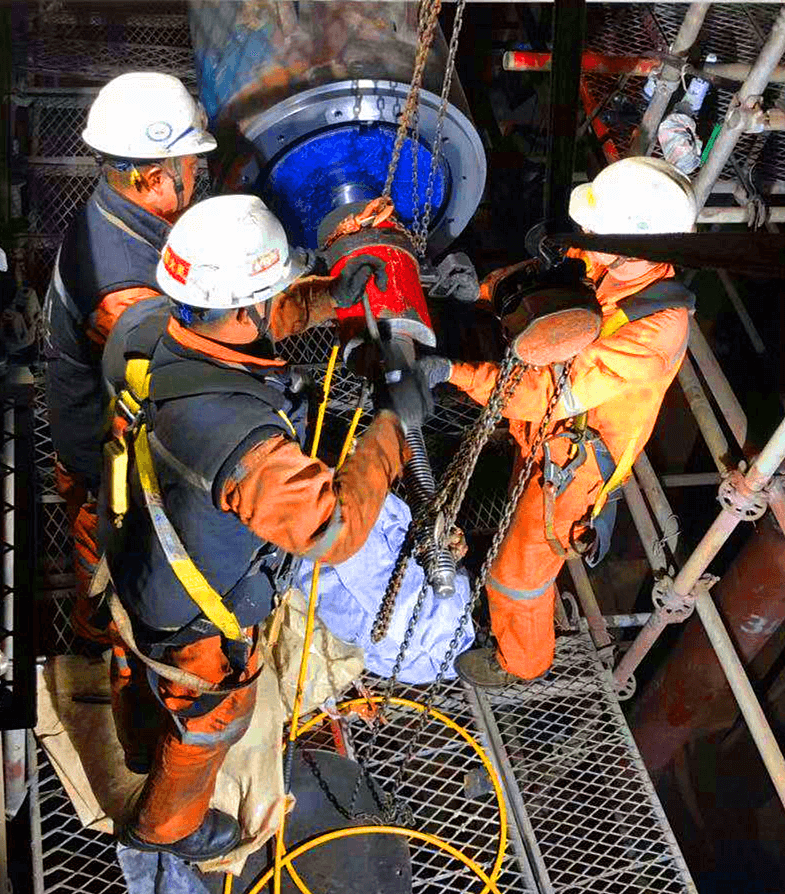

- In-situ line boring of Port and Stbd., forward and aftStern Tube Housings

- In-situ machining of Port and Stbd. forward and aft seallanding surfaces

- Realignment of Port and Stbd. intermediate stern tubebushes prior to Chockfasting

- Installation and assembly of stern tube bushes

GOLTENS’ WORKSHOP SCOPE

- Final machining of outside diameter of 6 new stern tube bushes

- Workshop machining of 2 new liners

- Reassembly of 2 sets of intermediate stern tube bearings and liners

THE RESULT

Goltens’ skilled technicians executed all required work to the satisfaction of the shipyard, owner and Class BV. Goltens completed the installation within 8 days and is scheduled to complete the same work scope on the second vessel.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now