Hyde Guardian ballast water treatment retrofit for ROV survey / construction vessel

3d scanning, modeling, detailed design engineering, pre fabrication and installation supervision

Goltens Oslo was contracted by Bergen, Norway based GC Rieber Shipping, a specialized offshore vessel operator, to support the design and installation for a Hyde Guardian Gold 300m3/hour ballast water treatment system retrofit .

As a strategic ballast water treatment engineering partner for Hyde Marine Inc., Goltens was well aware of the Hyde Guardian system’s capabilities and requirements and Goltens delivered a solution that would minimize the cost and timeframe required for the installation.

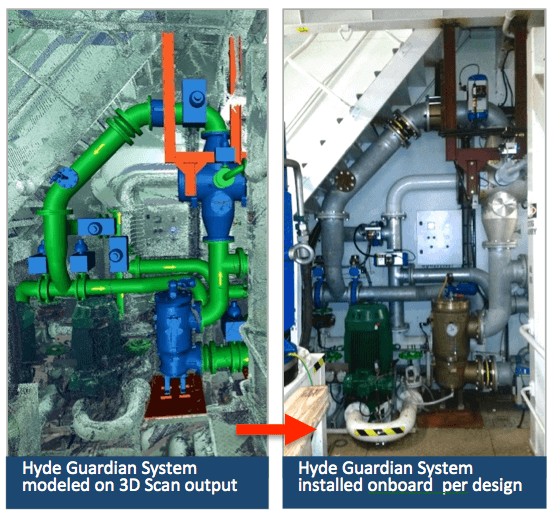

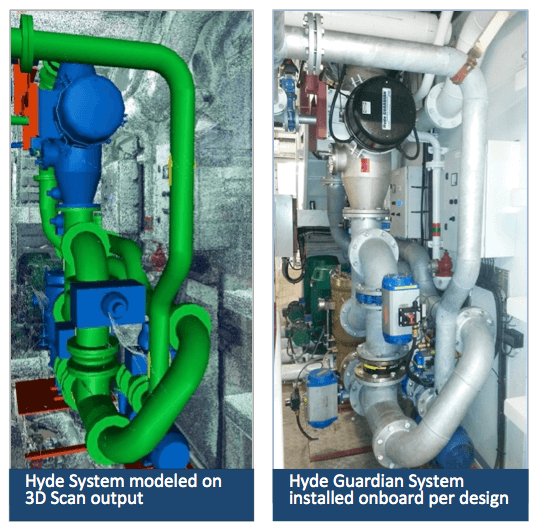

Following Goltens Green Technologies’ well-proven process for environmental compliance solution retrofits, Goltens began with a shipboard survey of the vessel and completed 3D scanning of the associated engineering spaces.

Given the vessel’s location, Goltens Oslo turned to Goltens Green Technologies resources in Miami to undertake the survey and scanning while the vessel was in the United States. Following that, the system was modeled and detailed engineering completed by Goltens Green in Oslo prior to the piping and installation package being prefabricated and delivered to the shipyard in US for installation.

PROJECT FACTS

| M/V POLAR QUEEN BWT SYSTEM | |

|---|---|

| Ballast Water System: | Hyde Guardian Gold |

| System Capacity: | 300m3/hour |

| Customer: | GC Rieber Shipping |

| Vessel Type: | ROV Survey / Construction Vessel |

HYDE GUARDIAN BWT SYSTEM RETROFIT SCOPE:

- 3D scanning & onboard survey

- Preliminary Modeling / Design

- Detailed Engineering

- Ship documentation update (Ballast Management Plan, Single line diagram, etc.)

- DNV Documentation Approval

- Delivery of complete material package including pre-fabrication and packaging of all piping, valves, foundations and pneumatic materials required.

- Supervision of system installation at US Gulf Coast shipyard

HYDE GUARDIAN BALLAST WATER TREATMENT RETROFIT RESULTS:

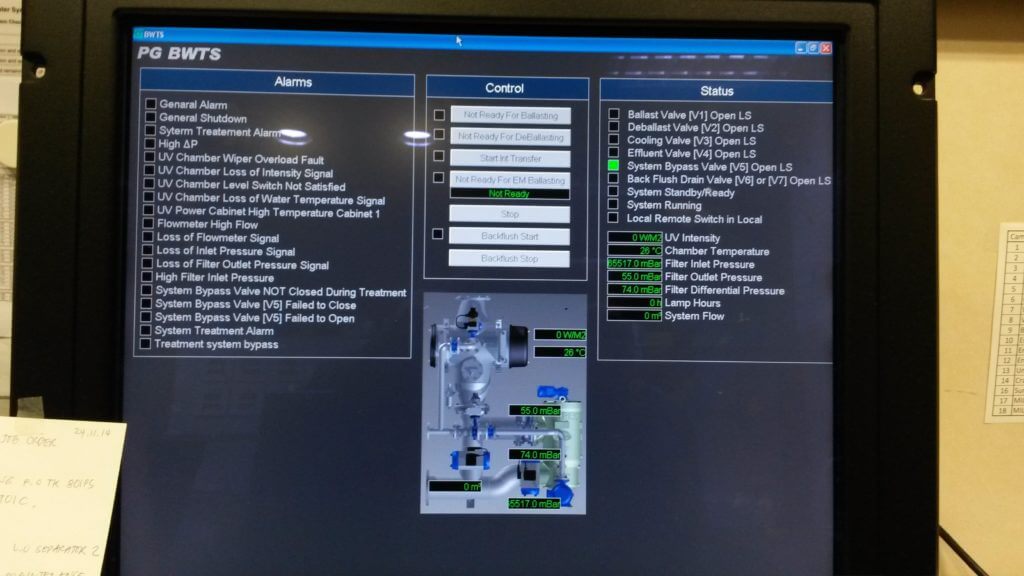

The installation and commissioning of the Hyde Guardian Gold system went off without issue and was reviewed and approved by vessel’s class DNV/GL.

The accuracy of the scan and design coupled with the accuracy of the prefabricated piping enabled the shipyard to install the system in a highly efficient manner once again proving the value of Goltens’ well-proven retrofit process.

CUSTOMER COMMENTS:

“Finally thank you for your assistance & support during the PQ scope of work. I will certainly recommend to anyone your services. It is important that owners collaborate with companies such as Goltens, mitigating the risk thus ensuring the owner’s investment is protected and effectively installed into an operational platform in the most efficient and cost effective means possible. You have been very professional, diligent & conscientious. Thank you, it was a pleasure working with you”

Stephen Lee

Technical Superintendent

GC Rieber Shipping

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now