In-Situ crankshaft machining

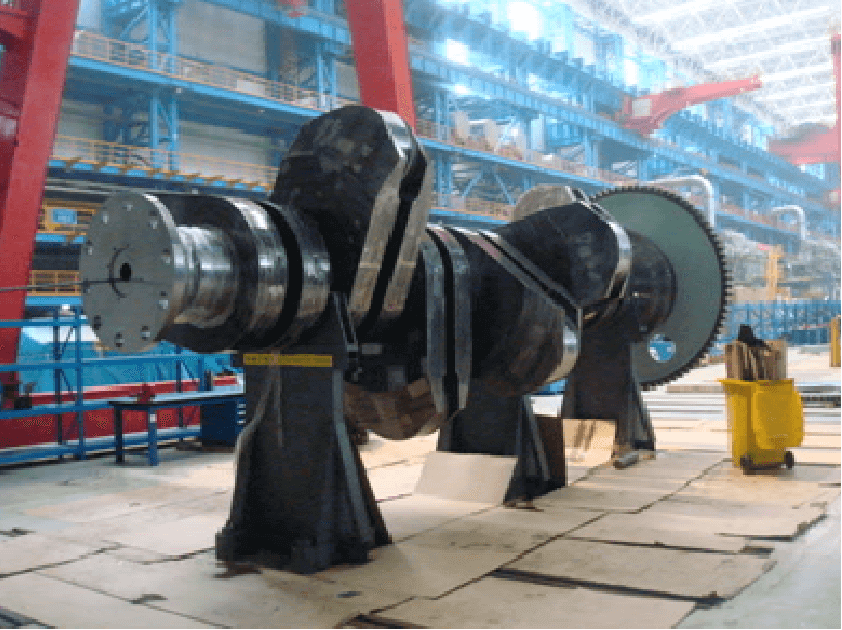

6RT-Flex-50B crankshaft renewal

Accidents happen in shipyard and factory environments, and when a forklift operator accidentally drove into a new Wartsila 6RT- Flex-50B crankshaft in China, a 600 mm crankpin was damaged and repairs needed to be done and done quickly.

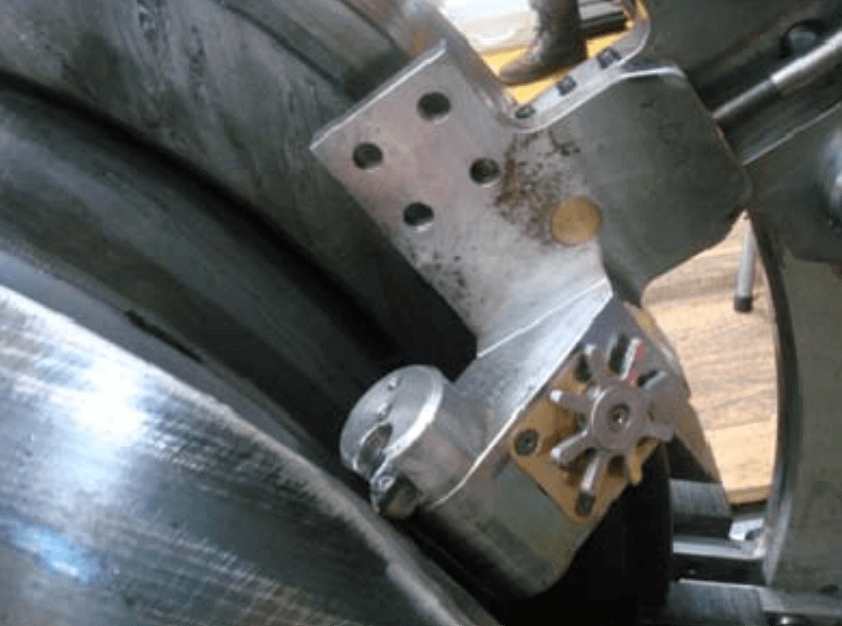

Goltens immediately mobilized an experienced team and a wide array of tooling to deal with the compact space available to machine the crankshaft. As the fillet radii were not true, the crankshaft had to be installed in the bedplate to provide a reference for the machining of the fillet radii. Once completed, Goltens then machined the damaged crankpin to a perfect finish diameter of 598 mm.

PROJECT FACTS

| Wartsila 6RT-FLEX 50B | |

|---|---|

| Weight: | 55 tons |

| Crankshaft Length: | 7560 mm |

| Throw: | 2850 mm |

| Journal Diameter: | 600 mm |

| Crankpin Diameter: | 600 mm |

REPAIRS

- Assessment of fillet radii (which were out of line due to the shaft manufacturing process)

- Machining new fillet radii for reference

- Machining crankpin journal to undersize 598 mm

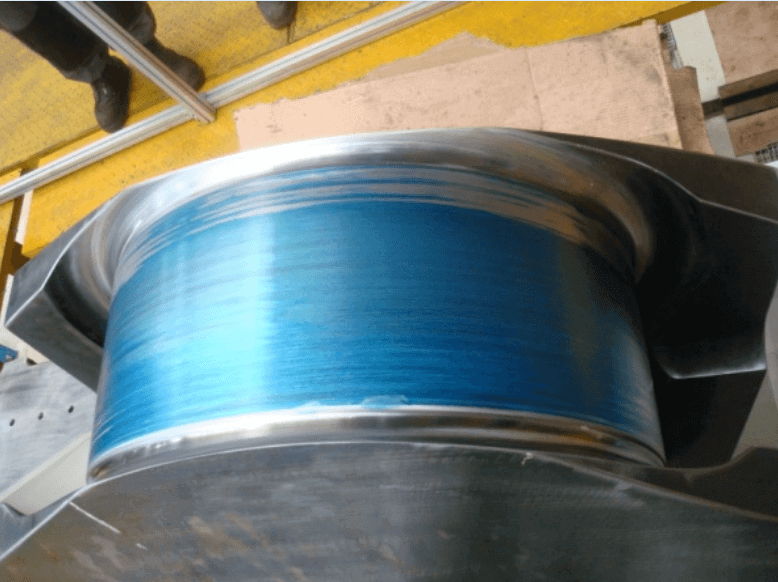

- Manufacture of bluing and lapping dummy

- Super polishing by machine

RESULTS

Goltens technicians completed this complex job in close association with the maker relative to the finite tolerance requirements in only 8 days of onsite work.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now