In-Situ crankshaft machining restores bulk carrier crankshaft

Mitsui B&W 5L42MC main engine failure – Taiwan

Goltens was contacted to perform an inspection of a 13- year-old bulk carrier’s main engine crankshaft after a casualty. The 18,320 DWT vessel’s single main engine was out of commission and the vessel was stranded in port in Koahsiung – Taiwan.

Goltens mobilized its tools and technicians to attend the vessel in Taiwan to rectify the damage as quickly as possible.

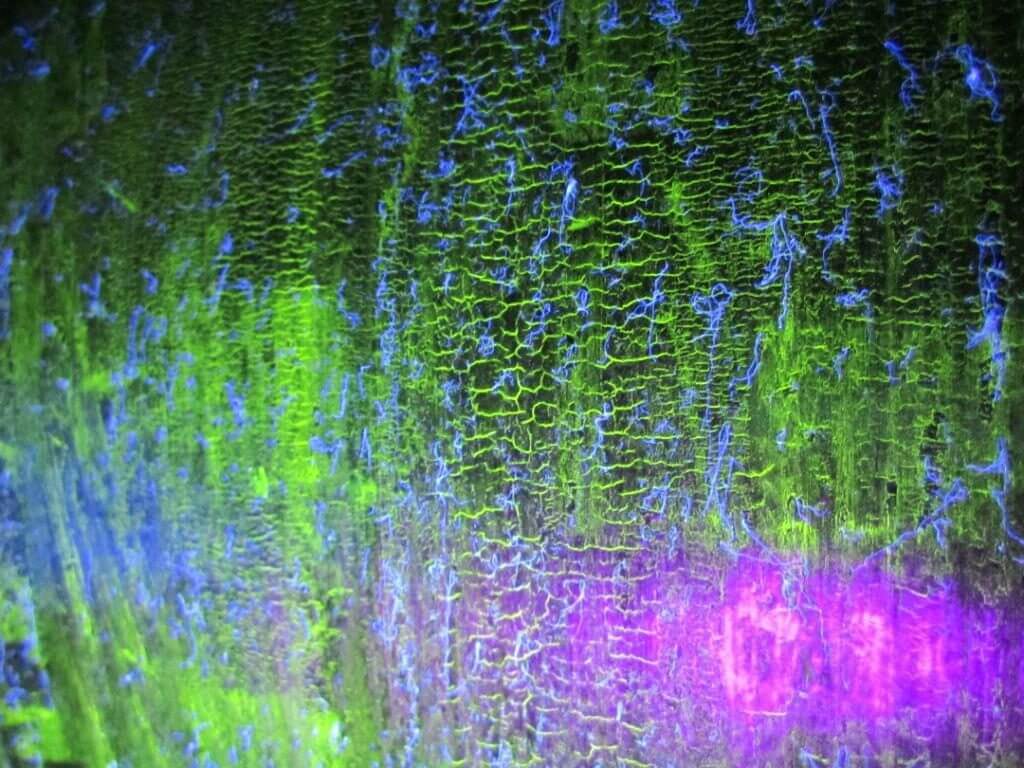

Once onboard the vessel the crankshaft journal surface was found to be full of cracks and the fillet radii were also found to be damaged. Goltens advised that new fillet radii be machined to provide a true reference for the journal machining and that the journal surface be machined clean to evaluate the extent of the damage.

After the new radii had been machined, Goltens’ in-situ machinists machined the crankpin to -4.00mm. At this point crack tests still showed several small cracks. Local grinding was performed to determine the depth of the cracks.

Goltens advised the client that the crankpin journal would be free of cracks and hardness at -6.00mm.

PROJECT FACTS

| MV BEAGLE VI | |

|---|---|

| Engine Make/Model: | Mitsui B&W 5L42MC |

| Engine output: | 4983 KW |

| RPM: | 176 RMP |

| Original Diameter: | 472mm |

| Post Machining Diameter: | 466mm |

| Work Location: | Kaohsiung – Taiwan |

IN-PLACE MACHINING SCOPE:

- Inspection of damaged Engine and Crankshaft including:

- In Situ crankshaft repairs:

- Hardness and Crack checks

- Run out measurements

- Machining of new fillet radii

- Machining of crankpin journal to -6.00mm to final diameter of 466mm

- Machine polished journal to finish roughness

IN-PLACE MACHINING RESULTS:

The entire machining job was completed in under 12 days and the vessel was returned to operation.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now