In-situ machining of chain table, turret head and I-Riser Tubes

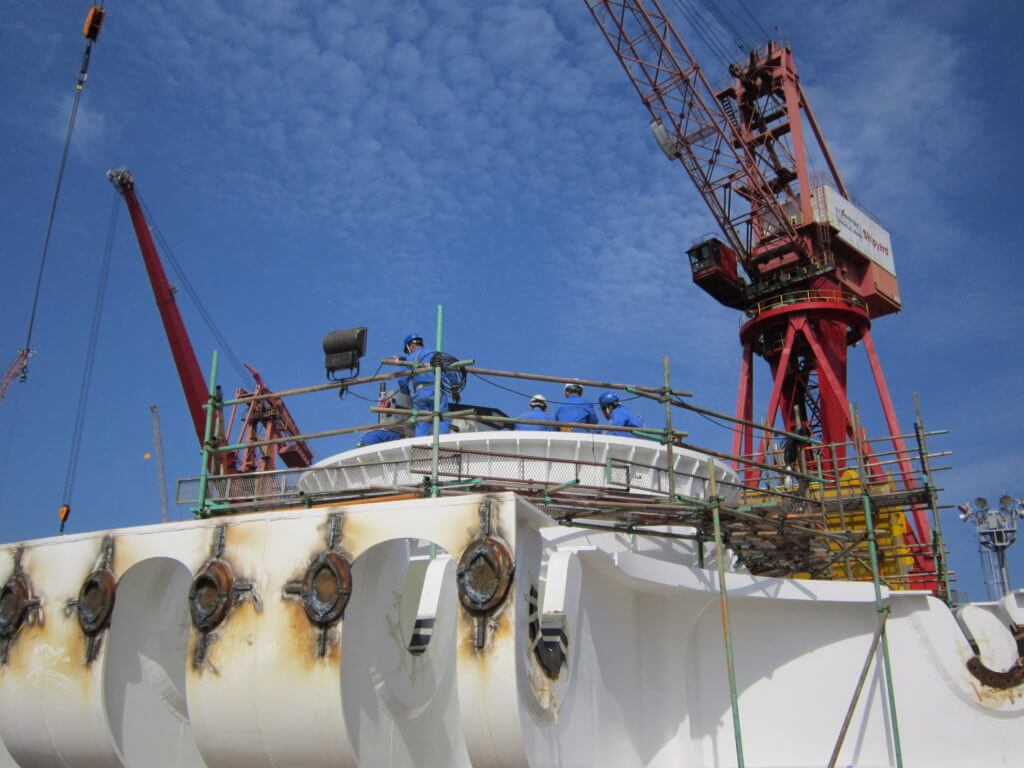

FPSO conversion in Singapore

Goltens carried out a critical On-Site machining job for an FPSO conversion in a local shipyard in Singapore. The job consisted of machining the Chain Table, Turret Head, flanges for the I-Riser Tube and Swivel Support. Goltens used a team of in-situ machining specialists with a 6-meter Orbital Milling machine and smaller flange facing machine to perform the jobs.

The job had its challenges, as setting up the 6 meter milling machine onto the Turret Chain Table was not a standard procedure. Normally the orbital milling machine is mounted with jacking legs to the inside diameter of the piece being machined. On the chain table, the inside diameter was blocked by other steel structures, so Goltens modified the machine to create a new foundation for the orbital milling machine tailored for this execution.

The 6 meter milling machine was then laser aligned to meet the machining tolerances set by the customer (flatness less than 0.15 micron and surface roughness to Ra 0.20um or better). Part of the scope also consisted of drilling 114 x 62mm bolt holes and Goltens fabricated a CNC machined template for marking and drilling the holes.

The same job scope was carried out on the opposed turret head flange for the swivel support.

PROJECT FACTS

| Turret Head, Chain Table, Riser-I Tubes and Swivel Support Machining | |

|---|---|

| Dimension of Chain Table: | OD 5,600mm x ID 5,190mm |

| Dimension of Turret Head: | OD 5,990mm x ID 5,580mm |

| Swivel Support: | OD 1,740mm x ID 950mm |

| I-Riser Tubes: | OD 1,330mm x ID 1,000mm |

TURRET CHAIN TABLE IN-SITU MACHINING

- Conduct Laser flatness checks on Chain Table

- In-situ machining turret chain table slewing surface (OD 5600mm x ID 5190) removing an average of 6mm from the surface with a tight control tolerance.

- Marking PCD 5374mm, drilling the slewing bearing surface Ø62mm x 114 holes and spot facing the holes 112mm.

- In-situ machining on 2 units I-Riser Tube riser flanges using smaller flange facing machines.

- Performed final laser alignment and surface roughness checks on Chain Table slewing bearing surface (Inclusive of the smaller I-Riser Tube riser flanges)

TURRET HEAD IN-SITU MACHINING

- Conducted Laser Alignment to check turret head flatness.

- In-situ machining turret head table slewing surface (OD 5,990mm x ID 5,580mm) removing an average of 10mm from the surface with a tight control tolerance.

- Marking PCD for 114 holes, drilling slewing bearing surface Ø62mm x 114 holes and spot facing slewing bearing surface Ø112mm on 114 holes.

- Performed final laser alignment checks and surface roughness checks on Turret Table slewing bearing surface.

IN-SITU MACHINING RESULTS

Goltens’ team completed the job within the defined schedule. The satisfied customer commented that Goltens was able to complete the complex job on time, the final results were excellent and the dimensions were extremely accurate.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now