In-Situ Annealing Saves Cruise Ship Crankshaft

In-Situ machining and annealing salvage sulzer 12 ZAV 40S crankshaft

During the running in of new big end bearings and bearing housing aboard a cruise vessel sailing in Alaska, Diesel Generator #5 experienced a casualty resulting in damage to crankpin journal #2.

Goltens met with the cruise line’s technical management and consultant and agreed upon a repair including: machining crankpin journal #2 to the next feasible undersize given by Engine maker and lapping and blue fitting of all other crankpin journals.

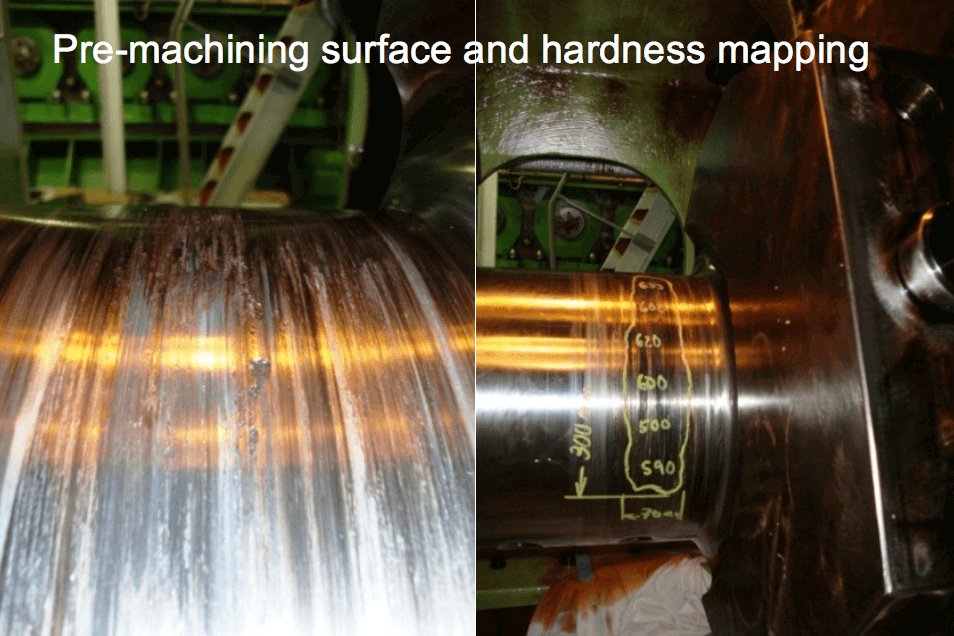

Inspection revealed that the crankpin journal was damaged all around the journal surface with scoring and bearing material. Additionally, technicians found a large area in the bottom side of the journal with hardness values above 600 HB. Run out measurements showed a maximum deficiency of 0.08mm.

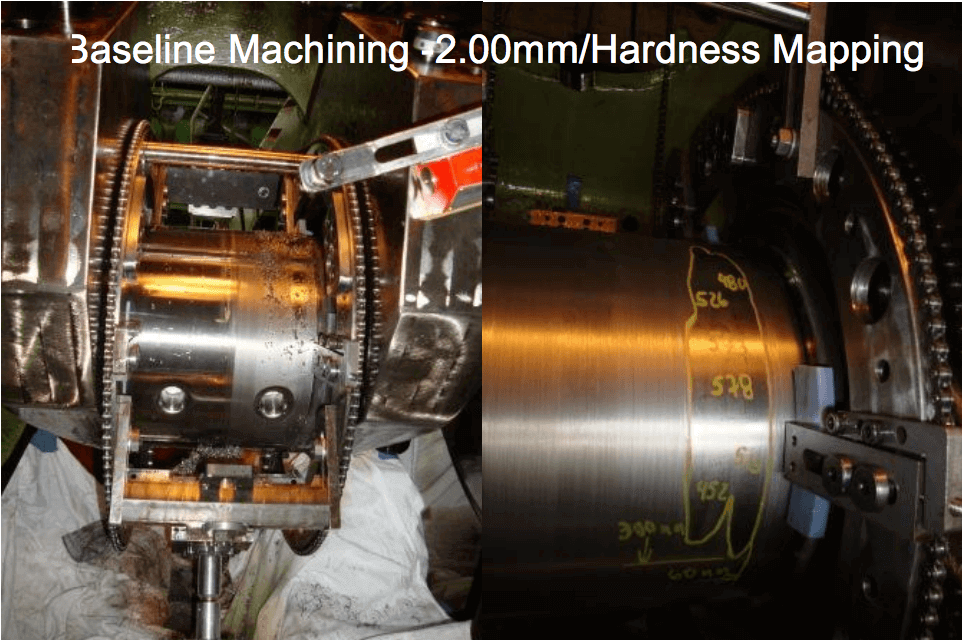

After assessment, the journal was machined down -2.00mm (diameter 348.00mm) until the damaged journal surface was clean of foreign material and cracks. However, the high hardness values remained.

The customer decided to cut another -2.00mm to see if the hard area would get smaller and the hardness values would get lower. At diameter 346.00mm the hardness values and area were still out of the engine maker’s specifications.

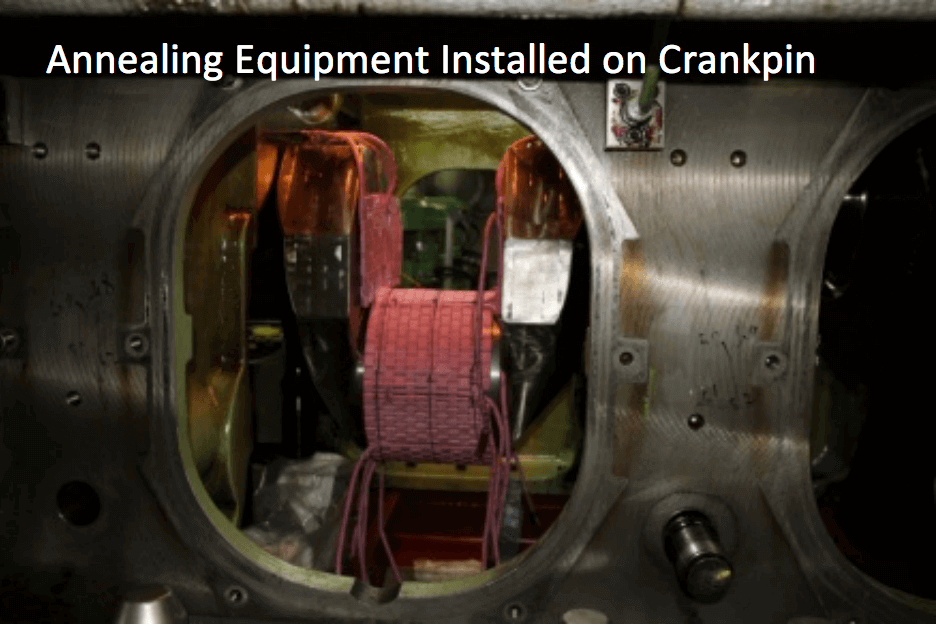

Goltens proposed performing its crankshaft annealing procedure to save the shaft within the maximum undersize diameter and hardness values given by the engine maker.

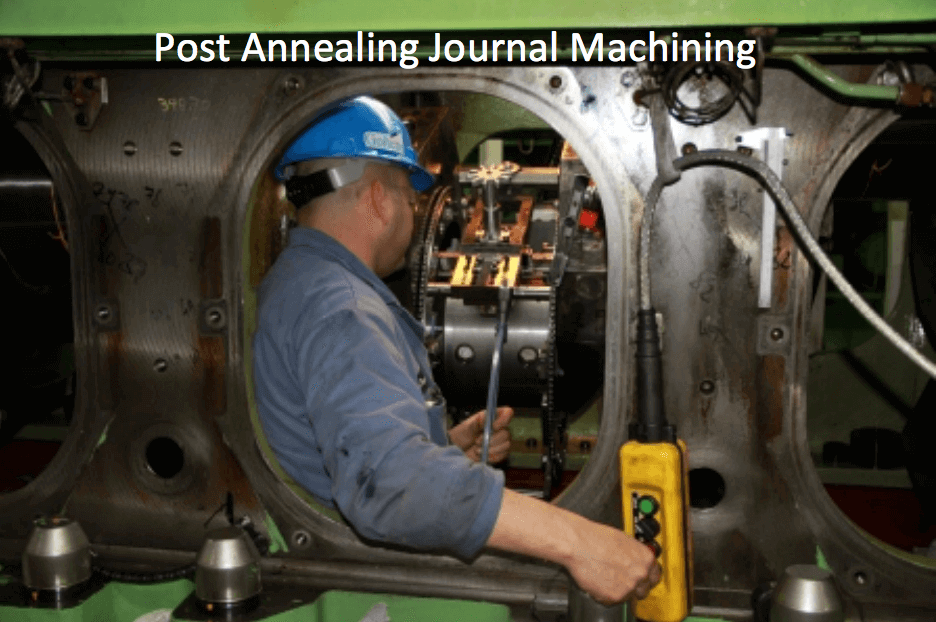

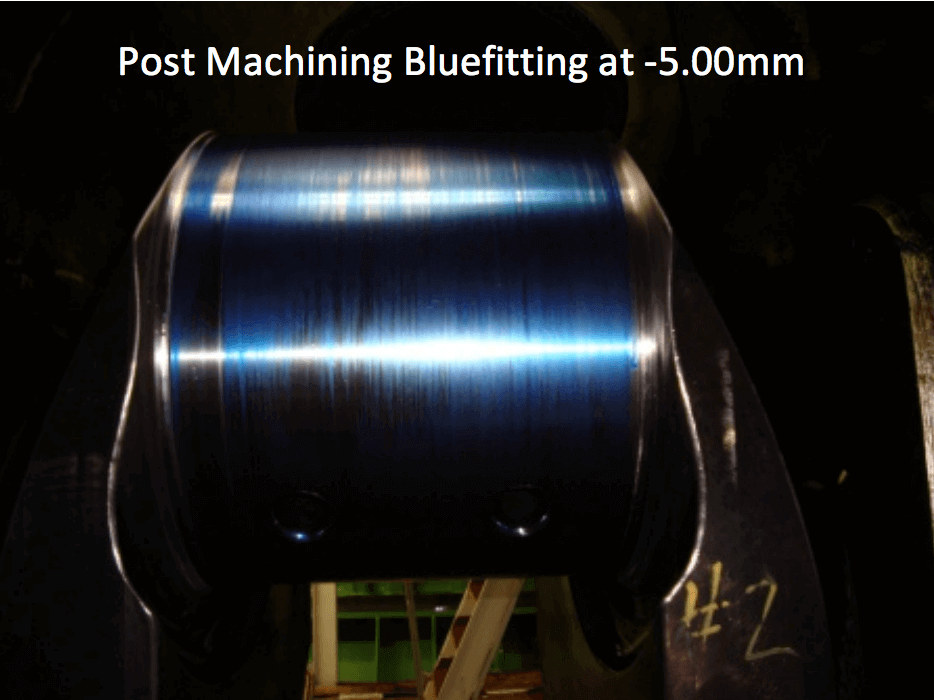

The annealing equipment was mobilized to Alaska and the engine was prepared for the annealing procedure. Once the annealing was completed according to the procedure submitted to the customer and Lloyds Register, the crankpin was machined to a final -5.00mm undersize (345.00mm). Post annealing hardness was measured under 300 Brinell.

PROJECT FACTS

| Engine: | Sulzer 12 ZAV 40S |

| Engine Output: | 8640kW |

| RPM: | 514 RPM |

| Original Crankpin Diameter: | 350.00 mm |

| Finished Crankpin Diameter: | 345.00 mm |

| Distance between Webs: | 272.00mm |

| Hardness Before Annealing: | 598 Brinell |

| Hardness After Annealing: | 296 Brinell |

REPAIRS

- Inspection of damaged Engine and Crankshaft including:

- Hardness and Crack checks

- Run out measurement

- Machining to 2.00mm undersize to remove cracks

- Machining to 4.00mm undersize to attempt to reduce/remove hardness

- Annealing of crankshaft to reduce hardness to acceptable levels

- Final machining and super polishing of journal to final undersize of 345.00mm (-5.00mm)

- Additional work consisted of:

- Machine polished crankpins #4, #5, #6

- Lapped and blue fit crankpins above to achieve surface contact area as per engine maker specifications while maintaining the standa

RESULTS

Goltens’ full spectrum In-Situ machining capabilities and its well tested annealing process reduced the hardness in the crankshaft to acceptable levels and saved the ship’s crankshaft and avoided a costly crankshaft replacement and unnecessary downtime. The vessel was kept in operation throughout the process and was restored to full capability in a highly cost effective and efficient manner.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now