Is a repair even possible?

Laser scanning, metal stitching and in-situ machining on Mitsubishi-MAN 6L 40/45 main engine after catastrophic failure

A main engine casualty by itself causes stress for engineers, owners and charterers, but when engine components seize and debris flies through the protective barrier of the crankcase, it is another matter altogether.

When staring at the interior of an engine through a hole that is not supposed to be there, the sight of extensive damage often leads to despair and thoughts of “what are we going to do now?” and “is a repair even possible?”

Goltens was called to answer these questions, when this nightmare turned reality aboard a 34-year-old rail vehicles carrier. Goltens specialists surveyed the engine and discovered, in addition to the large hole in the engine block, damage to the lower liner-landing surface, the crankpin, the counterweight-mating surface and bolt as well as the oil sump. Under other circumstances, the engine block may have been replaced. However, because of the age of the vessel, absorbing the massive cost of a replacement block was not an economically viable solution for either the owner or the insurer. Goltens’ proposal and demonstrated engine repair capability gave the owner the confidence to move forward.

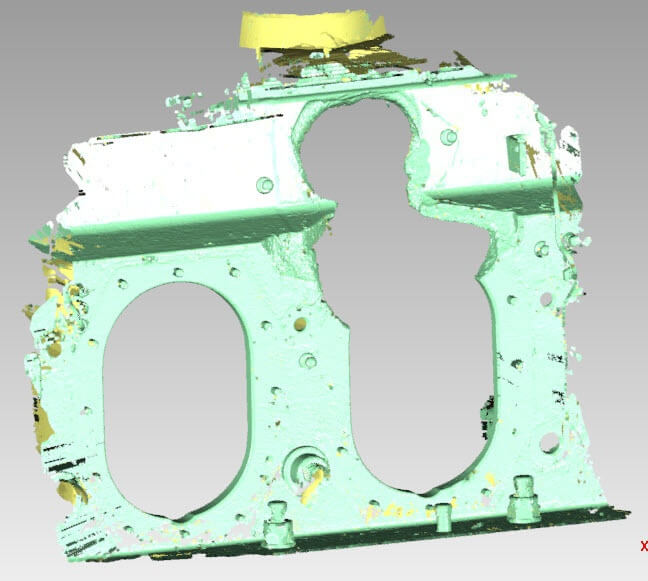

LASER SCANNING AND PREFABRICATION

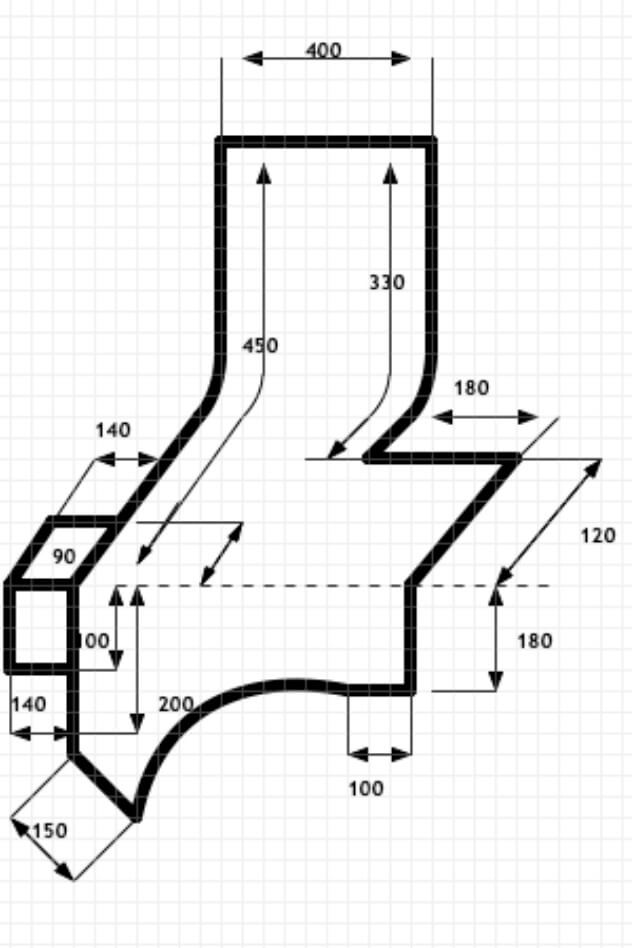

Cast metal repairs are a routine job for Goltens but due to the size of the hole and the angular or “stepped” surface of the block, Goltens performed 3-D laser scanning to provide the exact dimensions of the damaged area and performed extensive crack testing to ensure there was no damage extending farther into the crankcase. Drawings were then generated from the scan data and the large section was cast and milled along with an identical wooden dummy.

PUTTING THE PIECES BACK TOGETHER

While waiting for the cast piece to be fabricated, Goltens technicians cropped out the damaged section of the block to create smooth surfaces along the edges suitable for metal stitching. As the cast metal section was quite heavy, the wooden dummy was cut and shaped into the exact dimensions of the cropped section and used as a template to machine the cast section.

Once machined, the piece was rigged into place and Goltens’ In-Situ machinists began the long process of drilling and tapping the metal stitching pins along the long seams, drawing the mated surfaces together. Once this was completed, precision hole patterns were drilled and locks were inserted across the stitched joint line to reinforce the repair and distribute load stress away from the failure point.

THE OTHER “STUFF”

After the complex stitching process, handling the rest of the extensive damage, appeared more straightforward in comparison. Goltens’ in-place machinists tackled each area in turn, repairing the lower liner bore damage by line boring the surface and fabricating and installing an insert ring to return the section to standard dimensions.

They also repaired the damage to the crankshaft by machining the counterweight-mating surface and installing the counterweight with a fabricated pin and new studs and nuts and repaired the damage to the journal surface by machining 1.00mm from the crankpin. Lastly, Goltens’ welders repaired the sump damage that was caused by the flying debris and welded a replacement section into place. Once all of the repairs were completed, Goltens’ technicians rebuilt the engine and completed dock trials before the engine was turned over to the ship’s crew and returned to service. All repairs were reviewed and accepted by the vessel’s class society.

PROJECT FACTS

| METAL STITCHING REPAIR | |

|---|---|

| Engine Type: | Mitsubishi MAN 6L40/45 |

| Location: | United States |

| Engine Output: | 3,310 kW (4,500 hp) |

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now