In-situ annealing on Containership saves MaK 8M32 crankshaft

Costly crankshaft replacement and extended downtime avoided

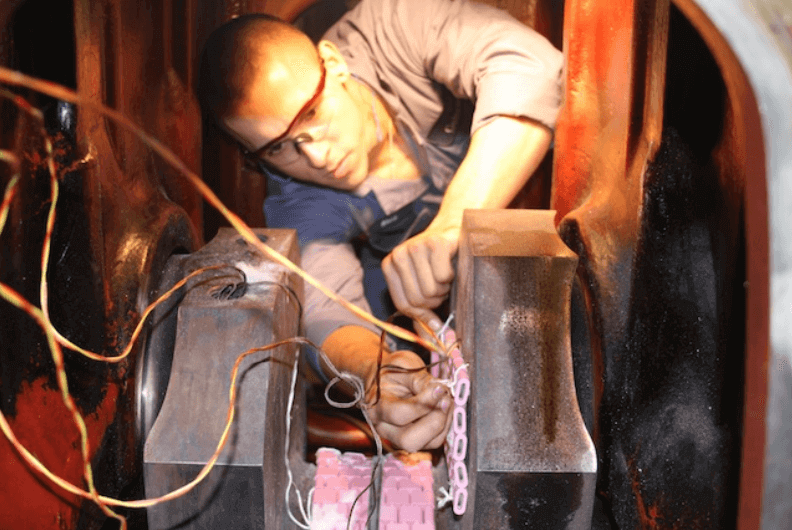

Goltens was contacted to perform a crankshaft inspection aboard the containership Caribe Mariner in Florida after its main engine suffered a connecting rod bearing failure.

The inspection revealed the journal had 0.5mm Ovality, cracks on the bottom side of the pin, run-out of .03mm and areas of high hardness up to 650HB. Complicating this repair was the 280.00mm journal could only be reduced by a total of 3.00mm and remain within MaK specifications.

Goltens removed 1.0 mm and a full assessment showed that some cracks remained and hard spots remained above 600 HB. After a further 0.5mm, the remaining cracks were removed but the hardness had not abated.

With only 1.5mm remaining to save the shaft, and enable the Owner to avoid the purchase and installation costs of a new shaft, Goltens proposed annealing the crankpin to reduce the hardness to within specifications. A repair plan and procedure was submitted and accepted by Bureau Veritas, pending a final inspection of the bearing after completion of the repair and a sea trial.

IN-SITU ANNEALING PROJECT FACTS

| Caribe Mariner | |

|---|---|

| Ship Type: | Container Ship |

| Engine Make: | MaK 8M32 |

| Engine Output Mcr: | 3,380kW/4,595HP (600RPM) |

| Crankpin Diameter (Original): | 280.00 mm |

| Crankpin Diameter (Finished): | 278.00mm |

| Max Hardness pre-Annealing: | 650HB |

| Max Hardness post-Annealing: | 308HB |

CRANKSHAFT AND JOURNAL REPAIRS

- Removed 1.50 mm from crankshaft prior to annealing

- Annealed crankshaft to reduce hardness to a maximum of 308BHV, well within MaK limits

- Removed a final 0.5mm after annealing to finish the journal at 278.00mm (-2.00mm undersize)

- Superpolished crankpin journal to acceptable roughness limits

IN-SITU RESULTS

Goltens completed the annealing and machining of the crankshaft, reassembled the engine and conducted successful sea trials on the engine Bureau Veritas’ and owner’s supervision. Expensive crankshaft purchase and replacement was avoided through the application of Goltens’ annealing process and the vessel was restored to service.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now