Full MAN B&W 9L52/55B Diesel Generator Overhaul

Full engine rehabilitation, crankshaft renewal & concrete foundation modification

Holcim Lebanon awarded Goltens a contract in March 2011 to perform a full overhaul and engine rehabilitation project on diesel generator #8, a 7.5MW MAN B&W 9L52/55B. The engine had been inoperative for more than 5 years and required significant repairs and modifications before returning it to service.

Holcim viewed the restoration of the diesel generator as essential to boost the plant total power capacity back to 66 MW, providing operational flexibility and increase back-up power required on an average plant load demand of 31 MW

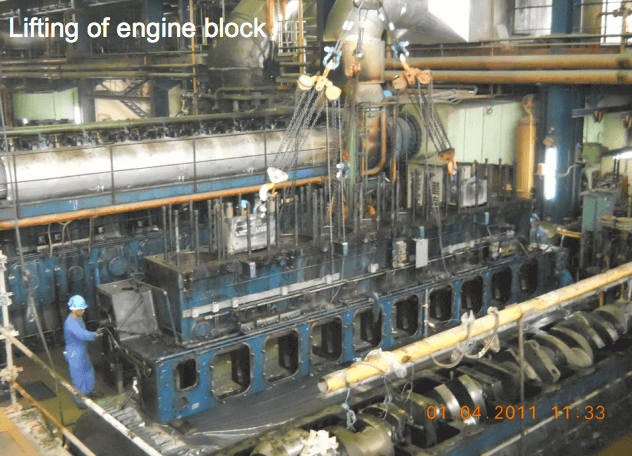

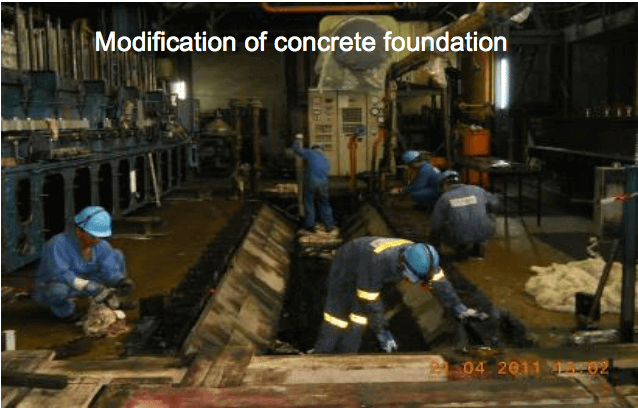

The scope of the project was significant as the foundation for the engine required renewal and the entire engine needed to be removed as part of the project.

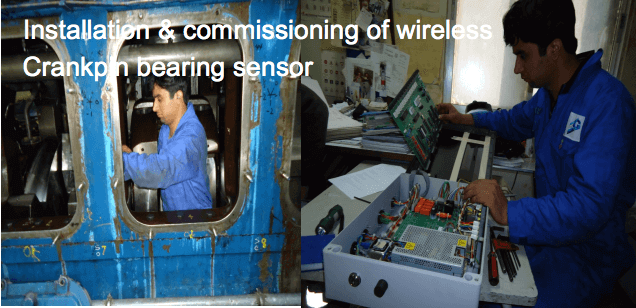

Goltens deployed a team of one Senior Supervisor, one Foreman and an average of 8 technicians to complete the mechanical work. Additionally, a team of Electrical Specialists was deployed to complete engine monitoring system upgrades which increased safety features by adding wireless crankpin bearing sensor monitoring.

MAN B&W 9L52/55B PROJECT FACTS

| HOLCIM LEBANON | |

|---|---|

| Plant Details: | 5 X MAN B&W 9L52/55 (32.5MW) 2 X MAN B&W 9L52/55B (15 MW) 1 X MAN B&W 18V 48/60 (18.5MW) |

| Total Plant Capacity: | 66 MWe |

| Total Plant Consumption: | 31 MWe Max |

DIESEL GENERATOR REPAIRS

- Disassembly and removal of complete engine from foundation

- Modification of concrete generator foundation using Chockfast Red .

- Overhaul of all engine components on site

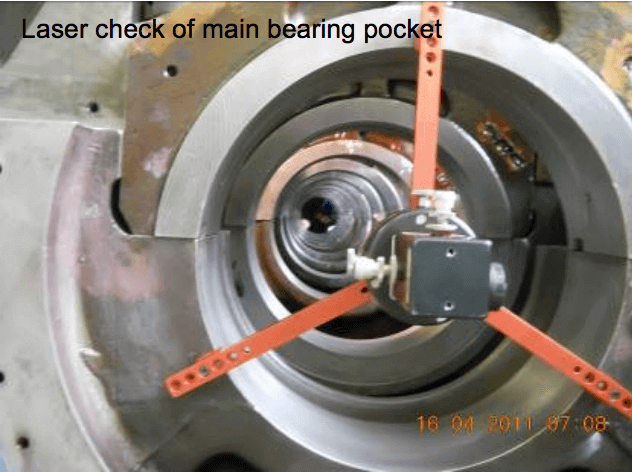

- Laser cheek of main bearing pockets

- Removal & installation of new crankshaft

- Installation & Commissioning of wireless crankpin bearing sensors

- Commissioning and 2 week reliability test of Engine

MAN B&W 9L52/55B DIESEL GENERATOR OVERHAUL RESULTS

During operational testing the generator reached 7.0 MW load with further capacity to increase to 7.5 MW as all operating parameters were demonstrated to be within maker specifications. The entire project was executed in accordance with the work plan and the Holcim plant was restored to full capacity with less vibration and increased engine safety features, optimizing equipment efficiency. Goltens full spectrum capability related to expertise in major engine repair, industrial Chock fast application and specialized electro/automation work enabled Holcim to engage Goltens for the end-to-end completion of this complex job.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now