Mechanical & Electrical Restoration - Fire Damaged Containership

YANMAR 6EY26L AUXILIARY AND MAN 7L70MC-C MAIN ENGINE REPAIRS

A 13-year-old, 35,555 DWT, Container Ship experienced a shipboard fire on its #3 Yanmar 6EY26L auxiliary diesel generator causing significant mechanical and electrical damage to itself, the adjacent #4 DG, and the engine space as a whole. As a result of the fire, the vessel lost power, use of the aux boiler and main propulsion for an extended period. As a result, upon power restoration, using backup generators, the emergency circumstance required starting of the MAN 7L70MC-C main engine under cold conditions after which the engine was operated for approximately 18 hours at slow speed to return to port.

INSPECTION AND MOBILIZATION:

With a long history of restoring shipboard fire damage, and as the authorized Yanmar distributor, Goltens Miami was contacted by the owner to assist with the inspection and restoration of the damaged Yanmar auxiliary engines. Additionally, Goltens was asked to complete the repairs on the main engine which, based on MAN inspection, showed heavy scuffing and scoring on the liners, piston rings and skirts as a result of the cold start operation of the main. Goltens was also awarded the required inspections and extensive repairs on the ship’s electrical systems damaged during the fire.

Goltens mobilized combined multi-functional teams from Goltens Miami and Houston for the engine and electrical work scopes.

AUXILIARY ENGINE REPAIRS:

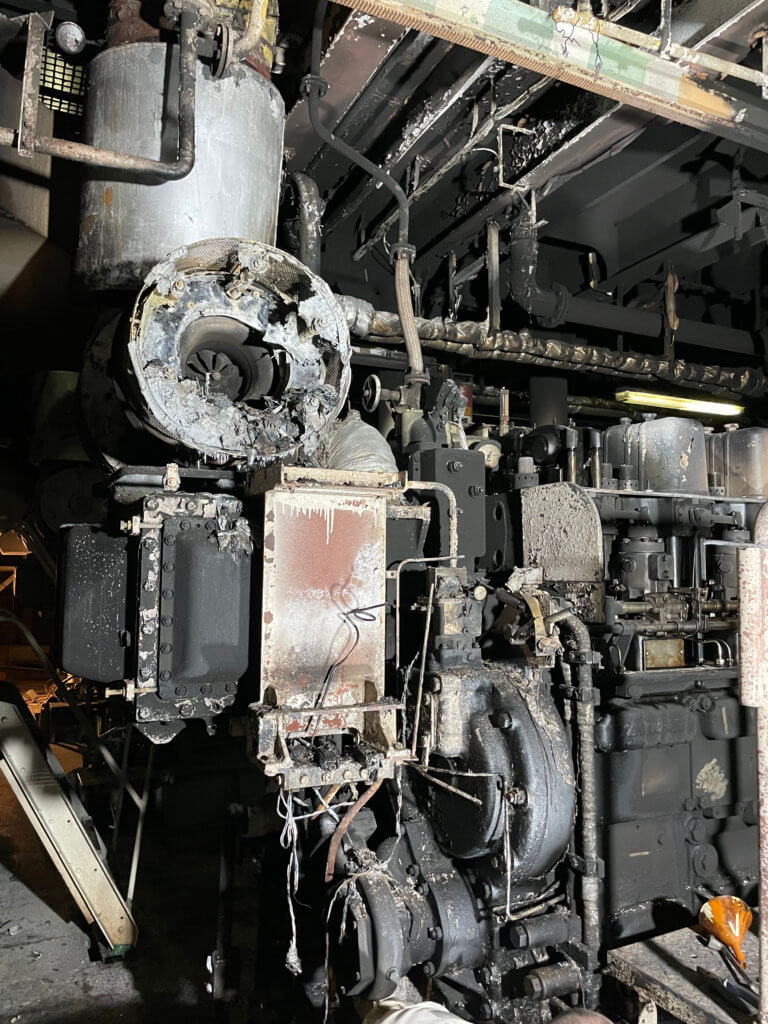

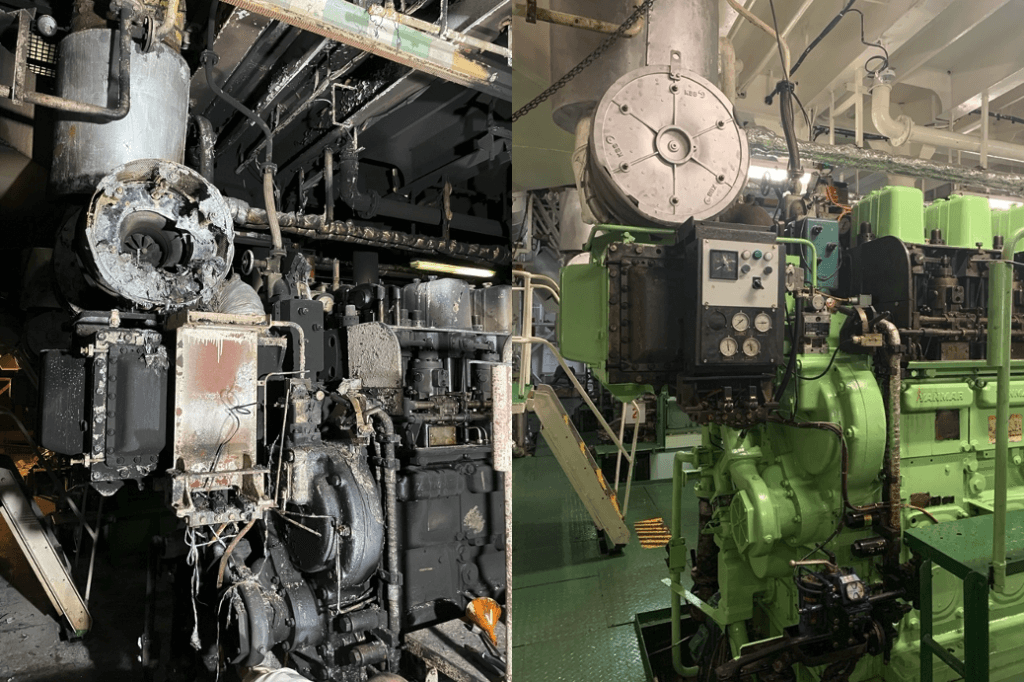

DG#3: As the fire originated from generator #3’s fuel piping and filter arrangement, the engine was exposed to direct and radiant heat that damaged wiring harnesses, cabling, sensors, panels, and machinery. The engine was disassembled in full, removing all heads, connecting rods, liners, turbo charger, coolers, and auxiliary pumps. Engine components were sent to Goltens Miami workshop for inspection and reconditioning where possible.

Further damage was found on the camshaft and crankshaft. Goltens In-Situ technicians polished numerous main and crankpin journals and the diesel team supplied and replaced the damaged camshaft section. The resilient mounts were all replaced due to fire damage and the governor and turbo charger cartridge were deemed a total loss and replaced. Goltens rebuilt the engine with a mix of new and reconditioned components (supplied by Goltens). Engine was realigned with the alternator prior to operational testing. The electrical team replaced all damaged wiring harnesses, cables, and sensors on the engine.

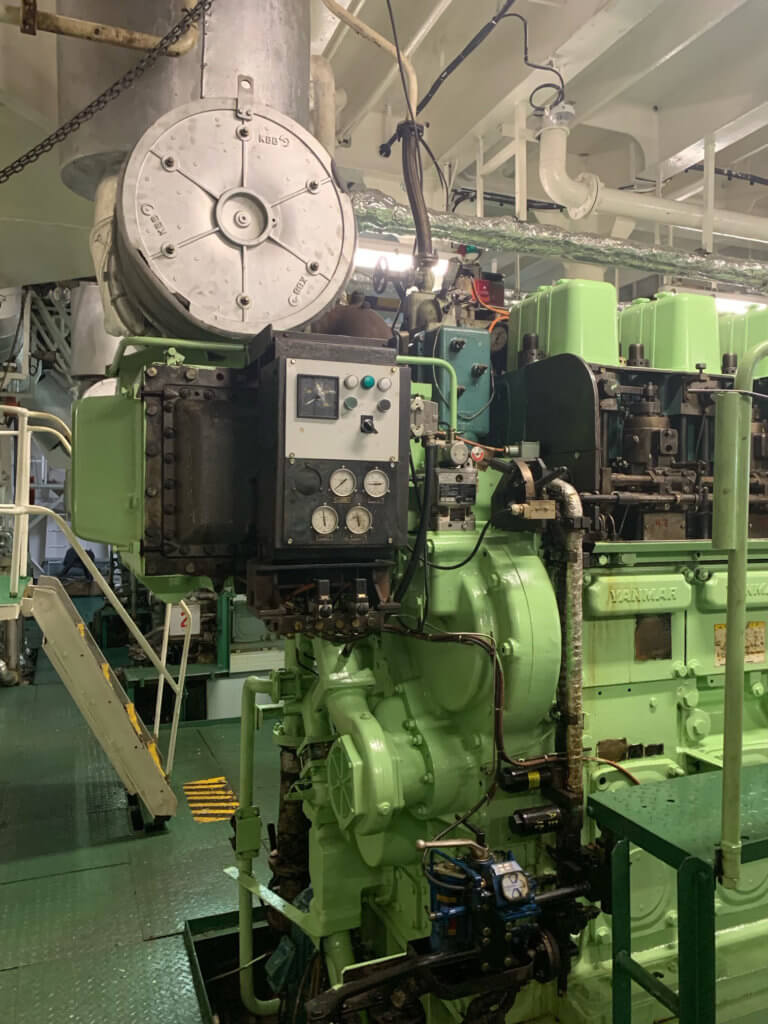

DG#4 (the next closest engine to #3) suffered damage to its wiring harness, cabling, sensors and panels and resilient mounts due to radiant heat. A mechanical inspection of cylinder #1 found all components in satisfactory condition with crankshaft deflection readings within tolerances. All resilient mounts were replaced. Electrical team repaired or replaced all the damaged electrical components and wiring, returning the engine electrical system into operation.

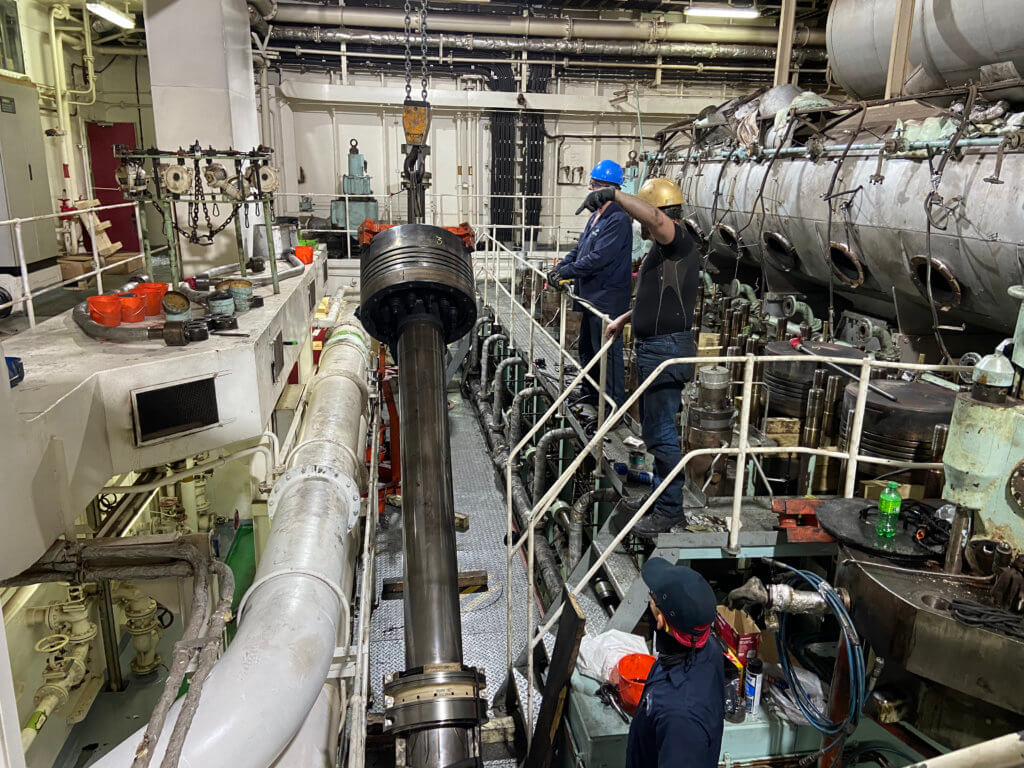

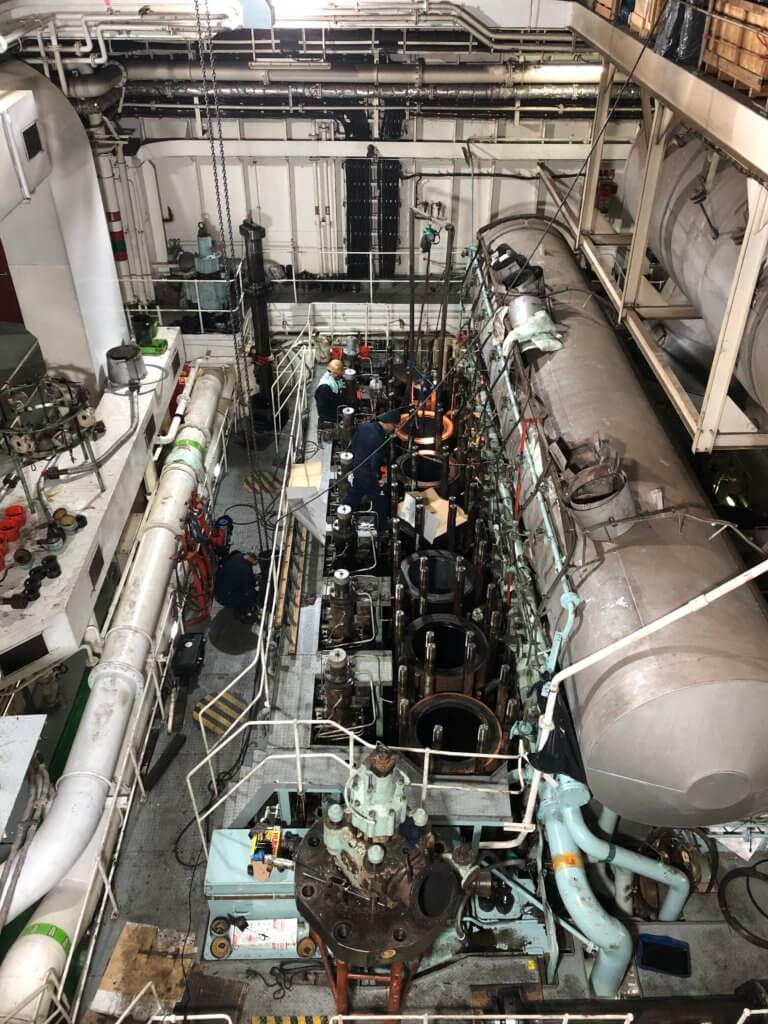

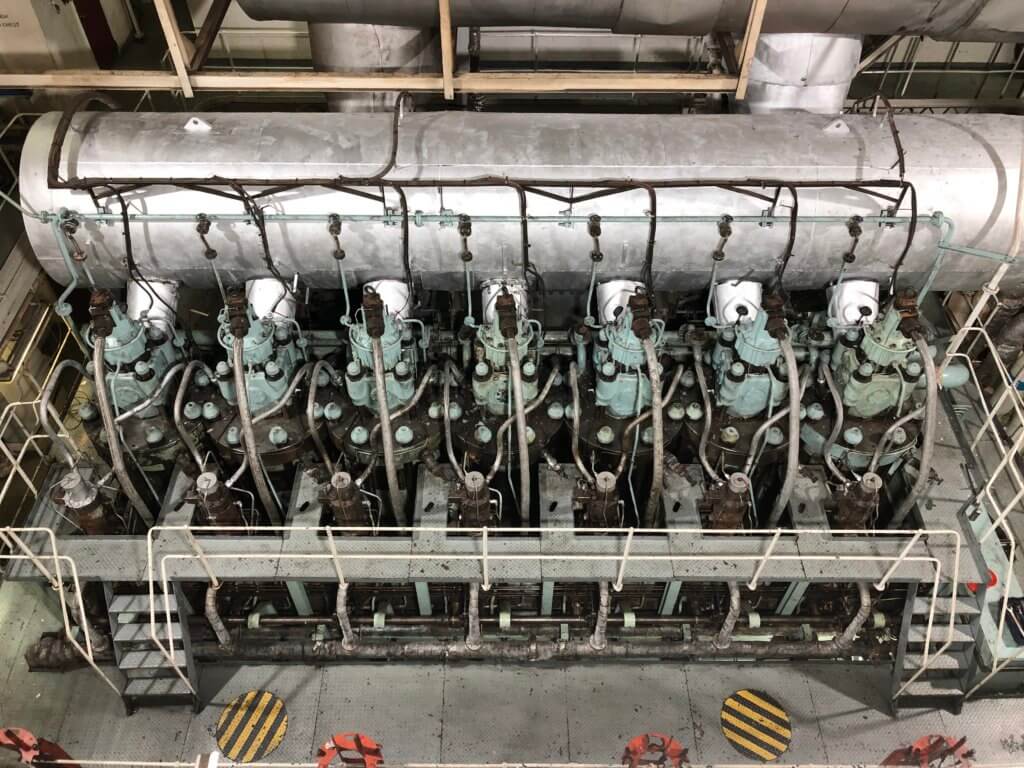

MAIN ENGINE REPAIRS:

Goltens’ team completed the disassembly of the main engine, and all units were inspected. The engine’s cylinder liners were honed or replaced, and the engine was reassembled with new or reconditioned skirts, crowns, bolts, o-rings, and piston rings. Finally, the engine was filled with jacket water and pressure tested to a satisfactory 4 bar. Once the aux boiler was operational, the engine was operationally tested.

ELECTRICAL INSPECTION & REPAIR:

All alternator power cables, stators, and excitation systems were opened, inspected, and tested and found satisfactory. Beyond electrical work on DG3 and 4, extensive repairs were carried out in the engine spaces from 3rd deck to F deck including: lighting, fire detection and alarm systems and the lube oil transfer and potable water systems, and the incinerator. Repairs included replacement of: cabling, detectors, sensors, defective switches and harnesses, and numerous damaged electrical motors and components.

RESULTS:

Goltens’ repair work was completed in 46 days with various components of the repair being completed earlier. Final testing of DG#3 was delayed pending receipt of a network card. Once received, the engine was tested successfully.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now