Multi-Station Execution Of Optimarin BWTS Retrofit

GOLTENS GREEN IN NETHERLANDS AND CHINA TEAM UP FOR SEAMLESS RESULT

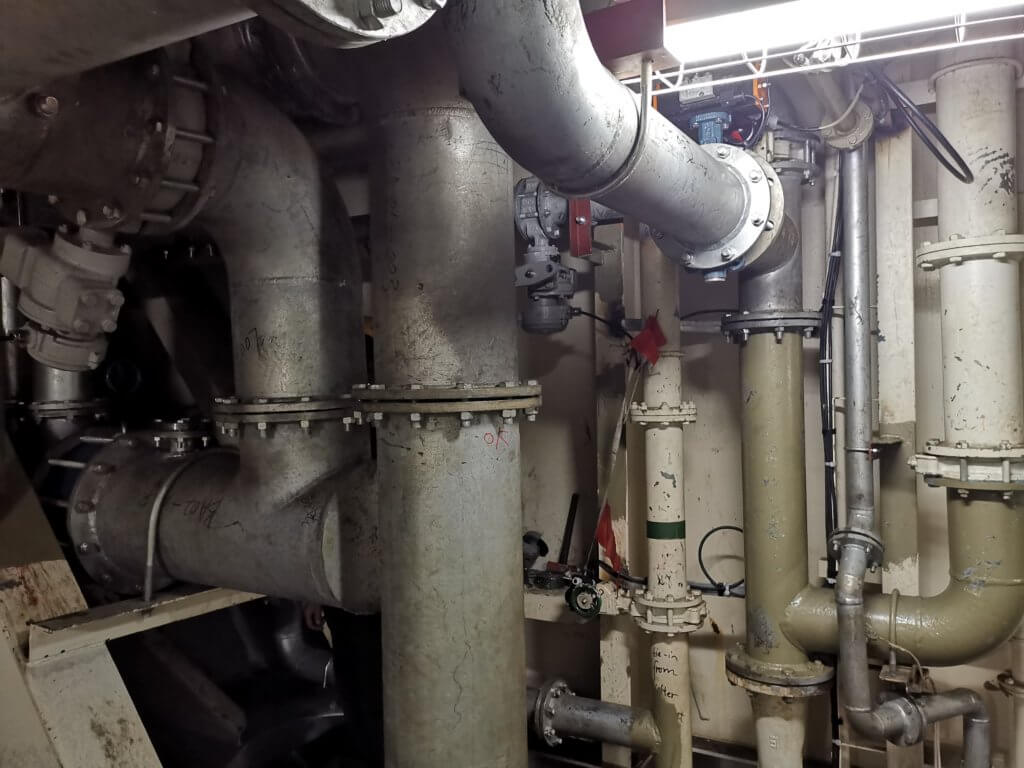

Optimarin initially engaged Goltens Green Technologies to undertake the 3D scanning, basic design and detailed engineering package for the retrofit installation on a 10-year- old, 37,000 DWT cargo vessel.

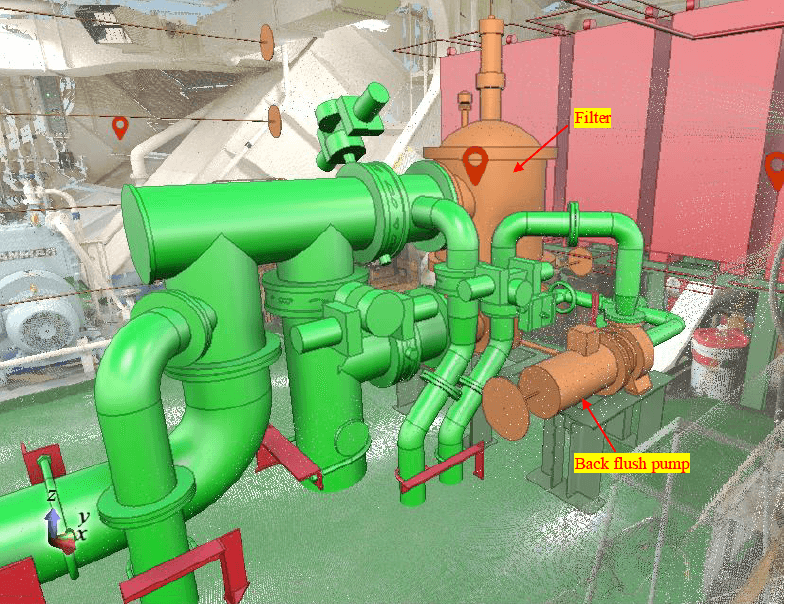

3D SCANNING AND DESIGN

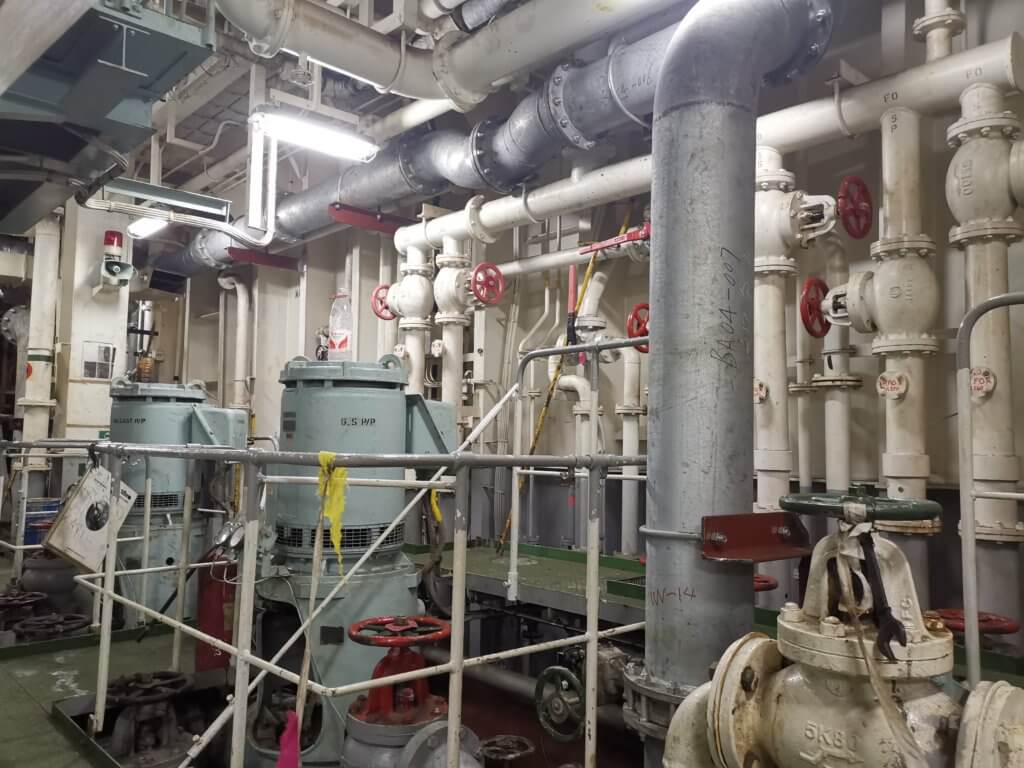

Goltens Green Technologies in The Netherlands reviewed the vessel’s schedule and, to limit the costs and travel, arranged to conduct the 3D laser scanning and vessel survey in Eemshaven, The Netherlands close to their offices.

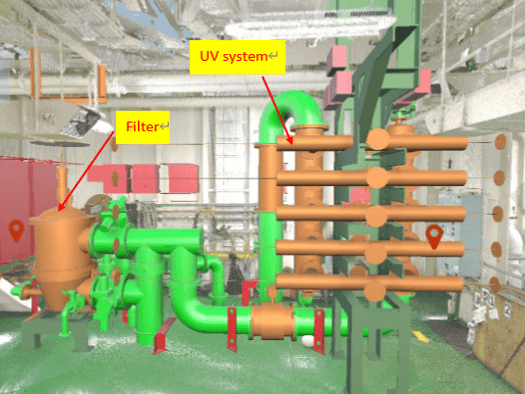

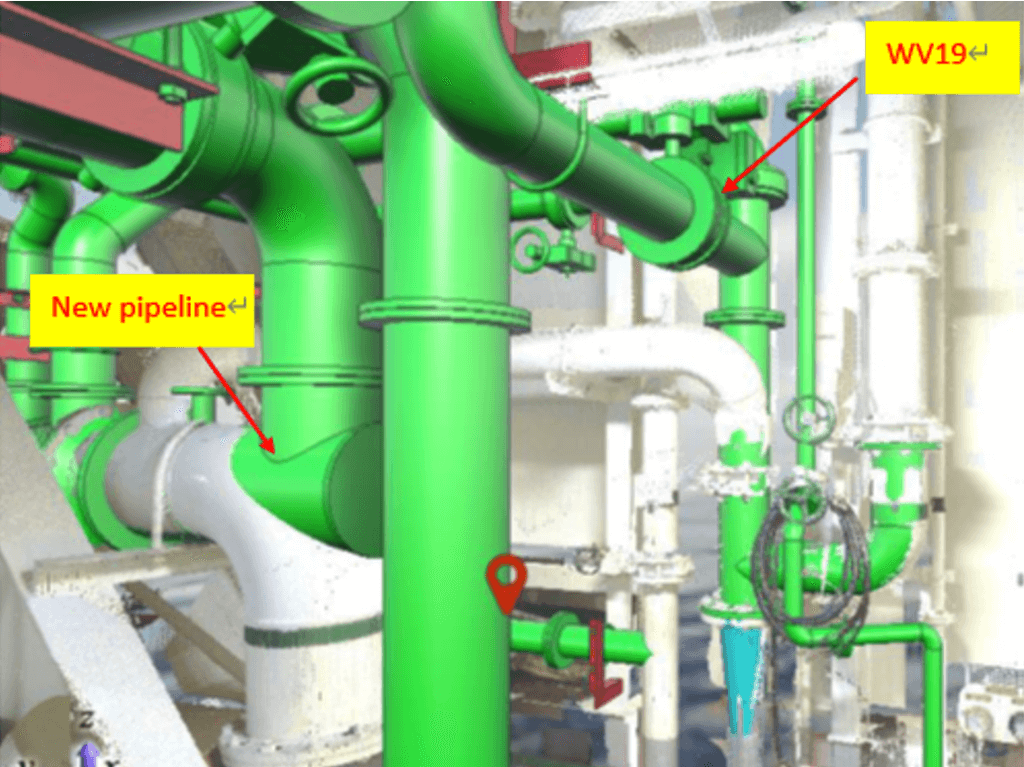

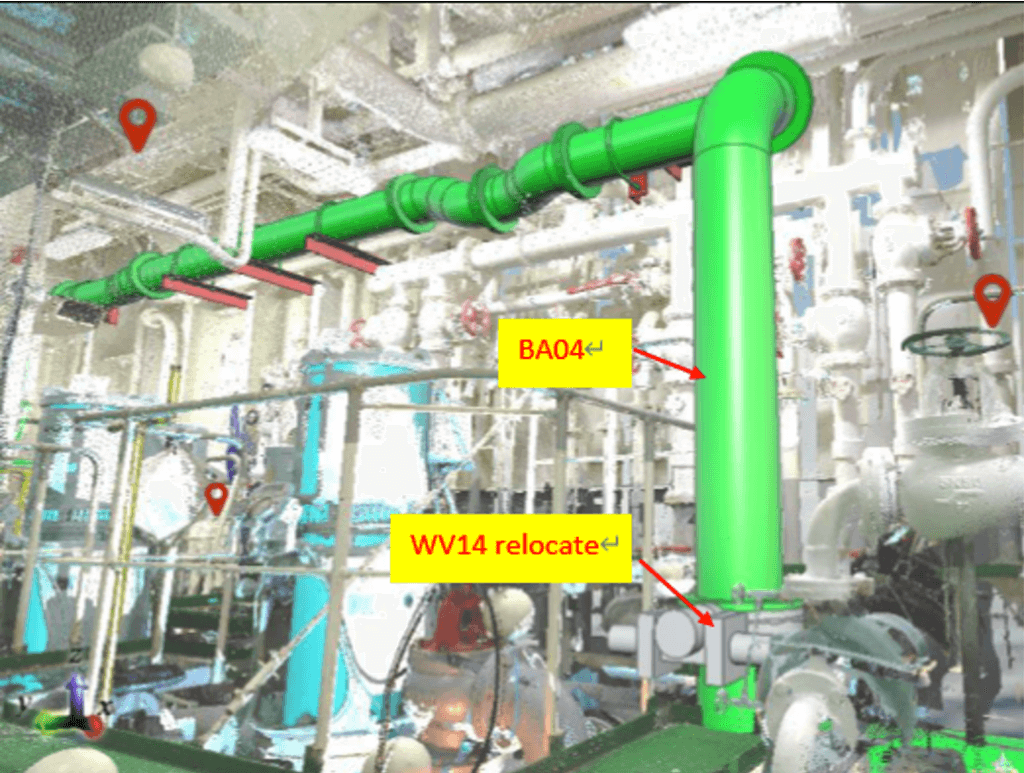

Using the 3D laser scan data, Goltens then completed the basic modeling of the system and reviewed it with the owner before embarking on the detailed design. Once the detailed design was completed, Goltens worked to develop the associated Ballast Water Management Plan and secured Class Approval.

PREFABRICATION AND INSTALLATION

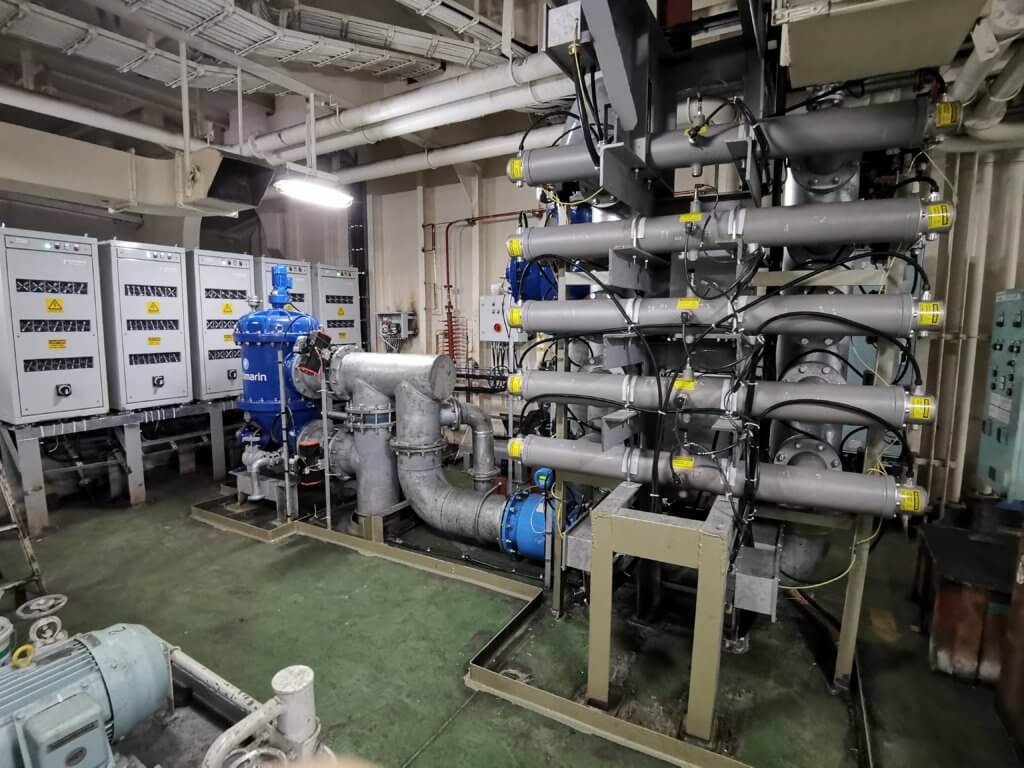

During this process, the owner confirmed that they would drydock the vessel at CUD (Weihai) Shipyard in China and expanded the scope of Goltens involvement. Goltens specialists in China were contracted to complete the prefabrication of the required system components and to perform installation supervision and commissioning of the Optimarin system while in the shipyard.

PREDICTABLY EXCELLENT RESULTS

Given Goltens China’s vast experience supervising BWTS retrofit installations, the installation and commissioning of the system went smoothly. All of the required components were prefabricated to finite tolerances made possible by the accuracy of the 3D scanning and were well organized with no pieces missing. Despite the inefficiencies and challenges introduced by COVID-19, the installation was completed, and the system was commissioned, in only 14 days.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now