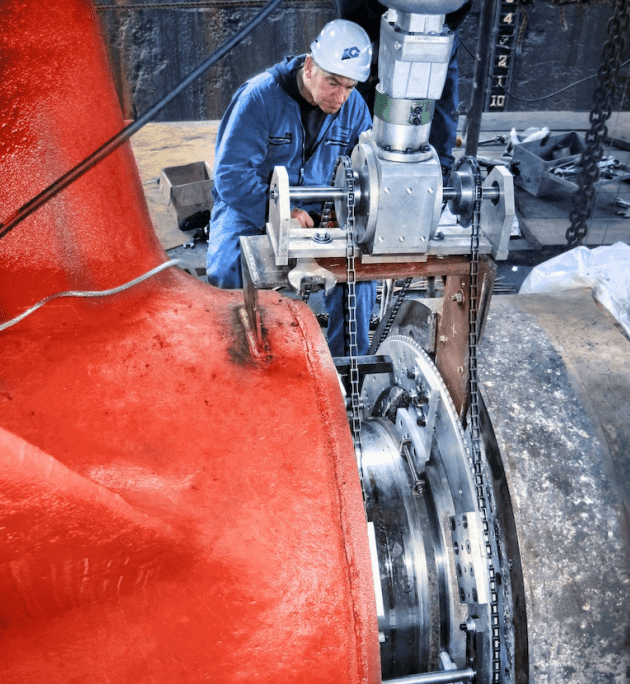

In-Situ tail shaft machining

Expensive shaft removal avoided with in-situ machining

Goltens was engaged to undertake the In-Situ inspection of the port and starboard tail shafts on a large military transport vessel while in dry dock. Inspection of the port and starboard tail shafts revealed that the Simplex shaft seal had worn deep grooves in the shaft liners.

The owner was faced with huge costs of removing the propellers and shaft and transporting the shafts to a workshop to have the shaft machined not to mention the time impacts on the yard period. Goltens proposed performing the repairs in place to both shafts to avoid these costs and extended downtime for the vessel.

Goltens immediately mobilized its journal machining tools and technician and began the job to restore the surface.

PROJECT FACTS

| Damaged Tail Shaft | |

|---|---|

| Original Shaft Diameter: | 850.00 mm |

| Finished Shaft Diameter Port: | 849 mm |

| Finished Shaft Diameter Stbd: | 846 mm |

| Length Machined Port: | 220 mm |

| Length Machined Stbd: | 190 mm |

ON-SITE PROPELLER AND SHAFT REPAIRS

- Machined and honed the port shaft 1.0mm to a final diameter of 849 over a length of 220mm

- Machined and honed the starboard shaft 4.0mm to a final diameter of 846mm over a length of 190mm

RESULTS

Goltens completed the on-site shaft repairs within maker tolerances for standard sized seals and enabled the customer to avoid the extensive costs associated with removal and transport of the shaft to a workshop. Work was completed on both shafts in roughly 10 days of onsite work.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now