OVERHAULING OF 10MW STEAM TURBINE & GENERATOR SET BY GOLTENS INDIA

LONG LEAD TIME AND COST LEADS TO COMPLETE OVERHAUL OF TURBINE IDLE FOR 10 YEARS

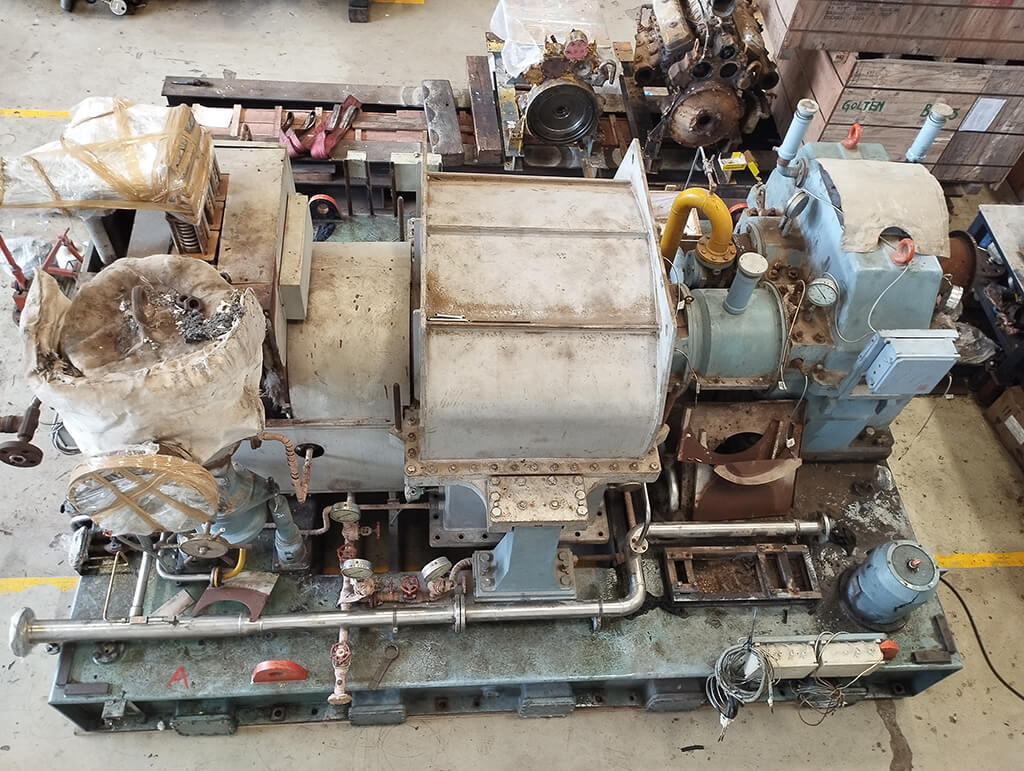

Goltens’ customer was engaged by an end user in Europe to supply and install a Steam Power Generation unit. They had discovered that lead times on a new unit were extensive and the costs prohibitive. As a workaround, the customer located an old turbine generator set in India that had been unused for roughly 10 years.

Goltens met with the customer and discussed options for reconditioning and overhauling the TG set and finalized the scope for the project.

THE INSPECTION

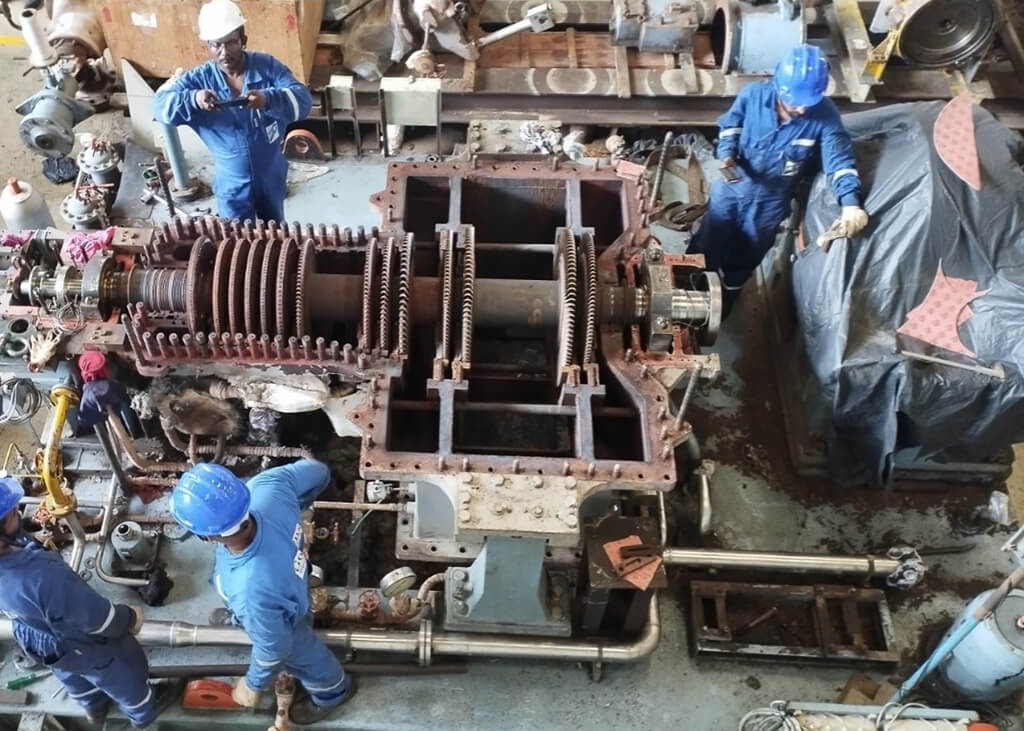

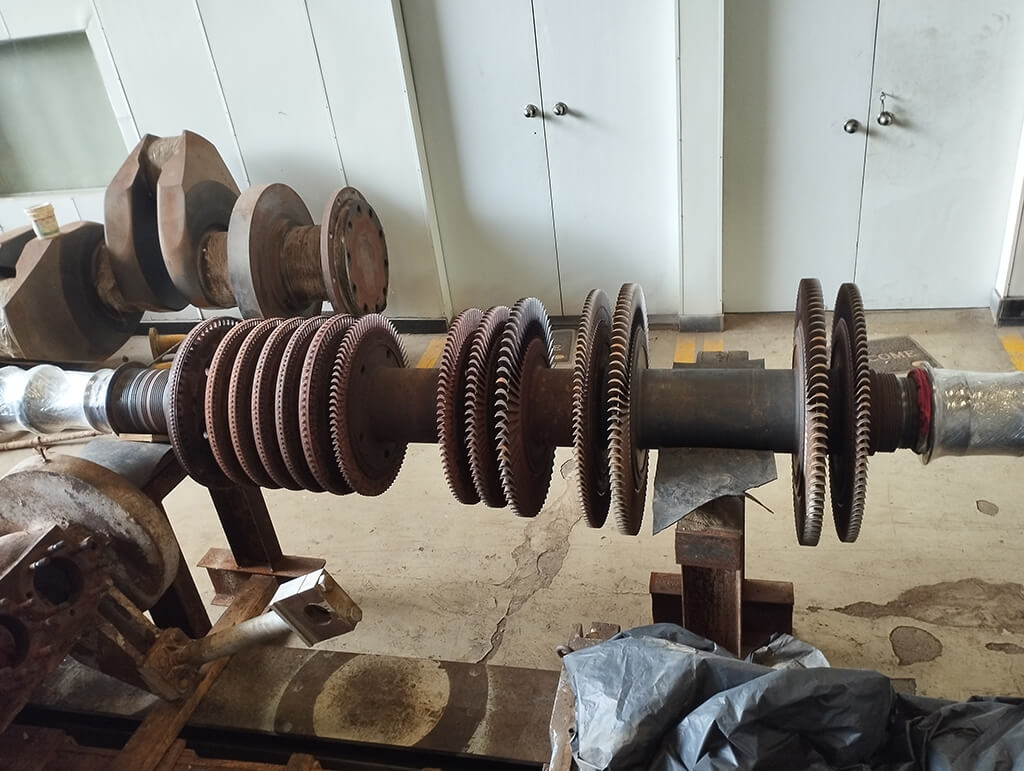

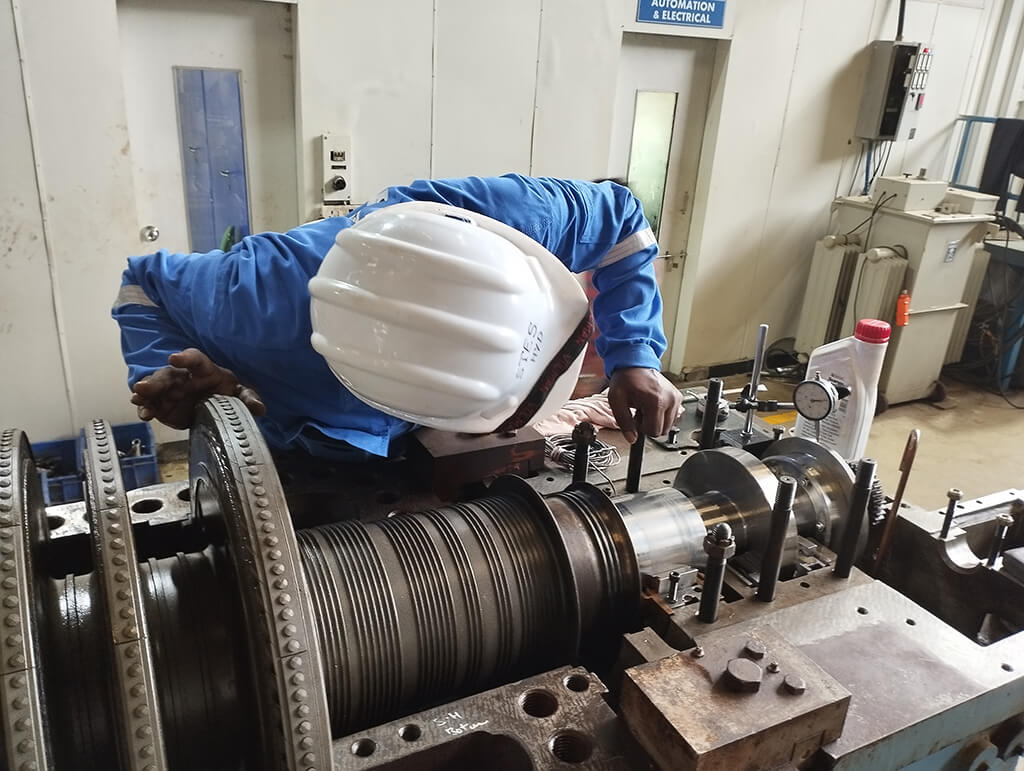

The customer delivered the turbine and generator to Goltens’ workshop for inspection. Complicating matters, no maintenance records, repair manual or supporting documentation was available. Once delivered, Goltens dismantled the steam turbine, gear box and generator and inspection revealed the components were in very bad condition with heavy pitting marks and significant rust from the long period of storage. Goltens determined that the repair of the turbine’s HP and LP blades and diaphragms would be a major challenge.

SCOPE OF REPAIR

- Full disassembly of turbine & gearbox

- Fine grit blasting of turbine casing, rotor, diaphragm

- NDT testing of all gearbox and turbine components

- Calibration of all parts and measurement of clearances

- Dismantling and cleaning of generator rotor

- CO2 cleaning, heating and varnishing of stator, rotor & exciter

- Electrical checks of generator and exciter winding

- Calibration check of turbine, gearbox and generator instrumentation sensors, gauges

- Electrical checks and overhaul of skid mounted motors

- Replacement of defective parts of turbine, gearbox & generator

- Overhauling and calibration of Woodward turbine actuator

- Final Turbine assembly with new parts, measurement, and correction of clearances

RESULTS

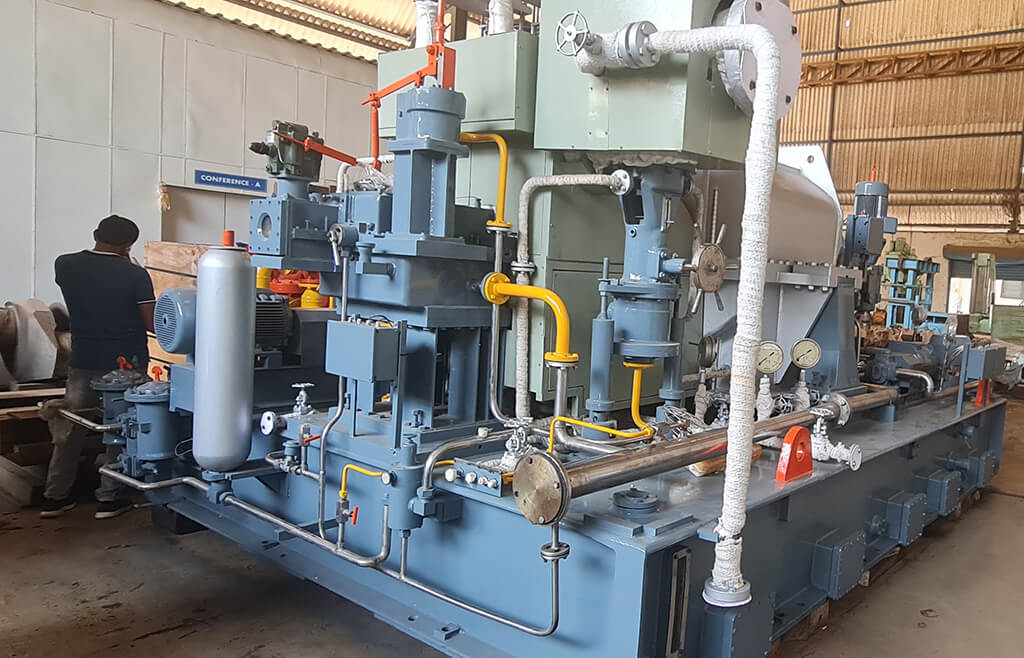

After replacement of 8 damaged turbine rotor blade stages, dynamic balancing, and reassembly, run out and clearances were checked and brought within OEM allowed tolerances. Blue contact checks were completed and a joint inspection with the customer and the end user was successfully completed. The entire generator set was then sprayed with a preservative coating and reassembled.

This challenging overhaul of an old and dilapidated generator set was completed within the committed timeframe and delivered to the customer’s satisfaction saving the customer and end user substantial time and expense.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now