In-Situ Annealing And Machining Restores Pielstick 2.5 Generator

Power station in French Guyana

A power plant in French Guyana contacted Goltens after experiencing a casualty on its #9 generator, a Pielstick 2.5 18V. Inspection revealed that crankpin number 6 had suffered a significant casualty resulting in significant damage to the running surface as well as the fillet radii.

Further evaluation also revealed extremely high hardness areas at both the top and bottom of the crankpin with peak values as high as 647hB (Hardness Brinell). Goltens discussed removing material from the journal until it was free of cracks and then remeasuring the hardness. At – 2.00mm the journal was free of cracks but the hardness remained with peak values of 600hB.

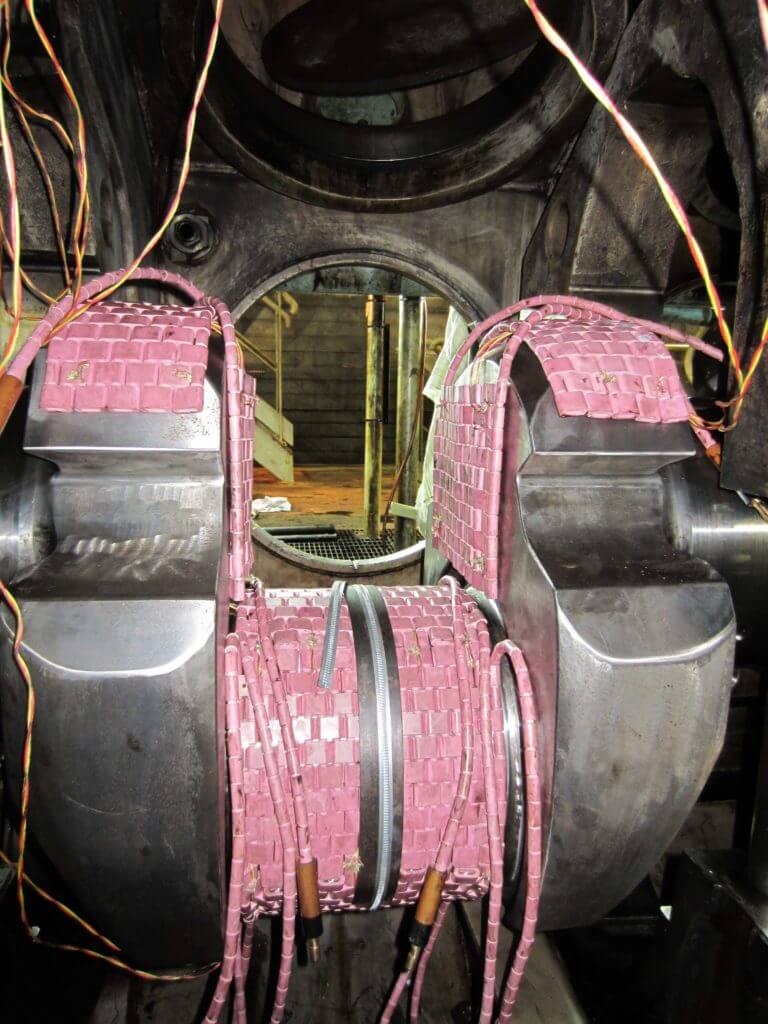

Based upon the extent of the hardness, Goltens estimated that it would extend, at a minimum, as deep as 6.00mm or more and advised the customer that it was possible to reduce the hardness via annealing and machine the crankshaft to an undersize of only -3.00mm. The customer accepted the proposed in-situ repair method and Goltens mobilized its annealing equipment and heat-treated the crankpin before finish machining and polishing the crankpin.

PROJECT FACTS

| French Guyana Powerplant | |

|---|---|

| Engine Make/Model: | Pielstick PC2.5 18V |

| Crankpin Dia. Pre machining: | 315mm |

| Crankpin Dia. Post machining: | 312mm |

| Max Hardness before Annealing: | 647hB |

| Max Hardness after Annealing: | 325hB |

REPAIRS

- Full NDT inspection (Magnaflux and Hardness)

- Machining of crankpin #6 to -2.00mm undersize pre-annealing

- Annealing of crankpin #6 to reduce hardness to below 325 hB

- Straightening of crankshaft

- Finish machining and superpolishing at -03.00mm undersize at 312.00mm

- Superpolishing crankpin # to less than 0.3Ra

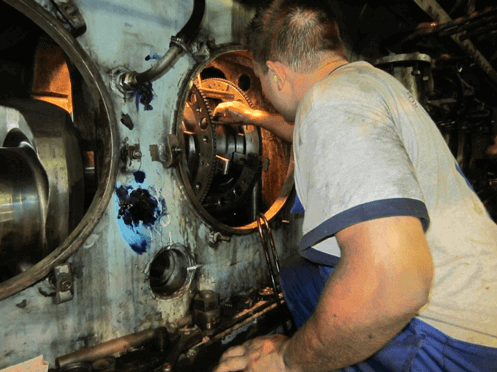

- Polishing / blue fitting crankpins 1, 2, 3, 4, 5, 7, 8 and 9

RESULTS

With annealing, Goltens was able to salvage the crankshaft with a much larger remaining diameter than if the customer had chosen to try to remove the hardness by machining underneath it. Additionally, the annealing process was faster and helped eliminate additional downtime for the powerplant.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now