Fast rebabbitting response keeps drydocking on schedule

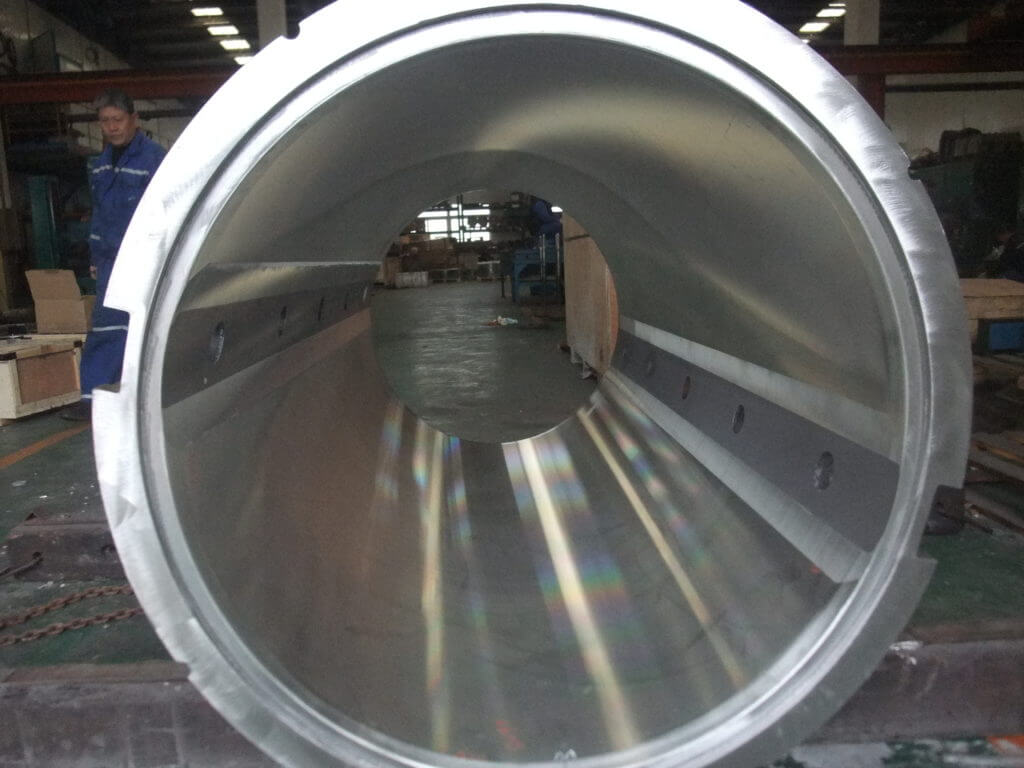

Forward and aft stern tube bearing rebabbitting & machining

During a drydocking period for a Crude Oil Tanker, babbitt material was found when the tail shaft was removed for inspections. Further investigation revealed that forward and aft stern tube bearings were damaged . The ship was under a tight schedule and the unanticipated work presented a serious challenge to keeping the vessel’s drydocking schedule.

The vessel’s chief superintendent recognized the seriousness of the damage and immediately approached Goltens knowing that Goltens had the workshop capabilities and specialized experience to solve the problem for the large diameter stern tubes.

Goltens responded immediately and dispatched an experienced supervisor to check the forward and aft stern tube bearings and tail shaft condition. After review, Goltens provided a proposal that was accepted by the owner and class representative from De Norske Veritas and Goltens began the repair.

PROJECT FACTS

| STERN TUBE BEARINGS | |

|---|---|

| Tonnage: | 298,555 DWT |

| Shaft dimension: | OD: 741.00mm × L: 1630.00mm |

| Year Built: | 2003 |

BEARING REMETALLING AND MACHINING REPAIRS

- Inspection of aft and forward stern tube bearings after removal old damaged white metal bearing material

STERN TUBE REPAIR RESULTS

Goltens coordinated closely with the shipyard and vessel’s class society and completed this rebabbitting project within 5 days in order to keep the vessel’s schedule on track.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now