Remetalling and Machining Restore Agitator Shaft

Crankshaft Remanufacturing Restores Agitator Shaft

Our skilled and experienced team restores crankshafts to their original specifications, ensuring top-notch quality and performance. Our meticulous process involves careful inspection, repair, and reconditioning of each component to meet the highest industry standards.

At Goltens, delivering superior results is our priority. Our skilled technicians use state-of-the-art equipment and advanced techniques to ensure precision and accuracy at every step. With our commitment to excellence, you can trust that your reman crankshafts will be restored to a like-new condition.

Contact us today to learn more about our services and how we can assist you.

GOLTENS’ IN-PLACE MACHINING RESTORES INDONESIAN POLYESTER PLANT TO SERVICE

A polyester plant in Indonesia was planning a shutdown in four weeks and suspected that the polyester reactor’s 285mm diameter agitator shaft was damaged and would require repair during the maintenance window. The maintenance window was short, and the extent of the repairs required was unknown.

Goltens deployed a team of specialists to the plant coincident with the shutdown of the plant. The team removed all the covers from the unit to complete the inspection. The In-Situ Specialist’s inspection revealed significant ovality and scoring/scratches on the journal’s running surface.

THE REPAIR

The extent of the damage would require Goltens to machine away the surface damage to restore the running surface. Complicating the repair, the customer required the diameter to be restored to the original 285mm so Goltens proposed a process to remove the damage, remetal the surface and machine the diameter to nominal measurement.

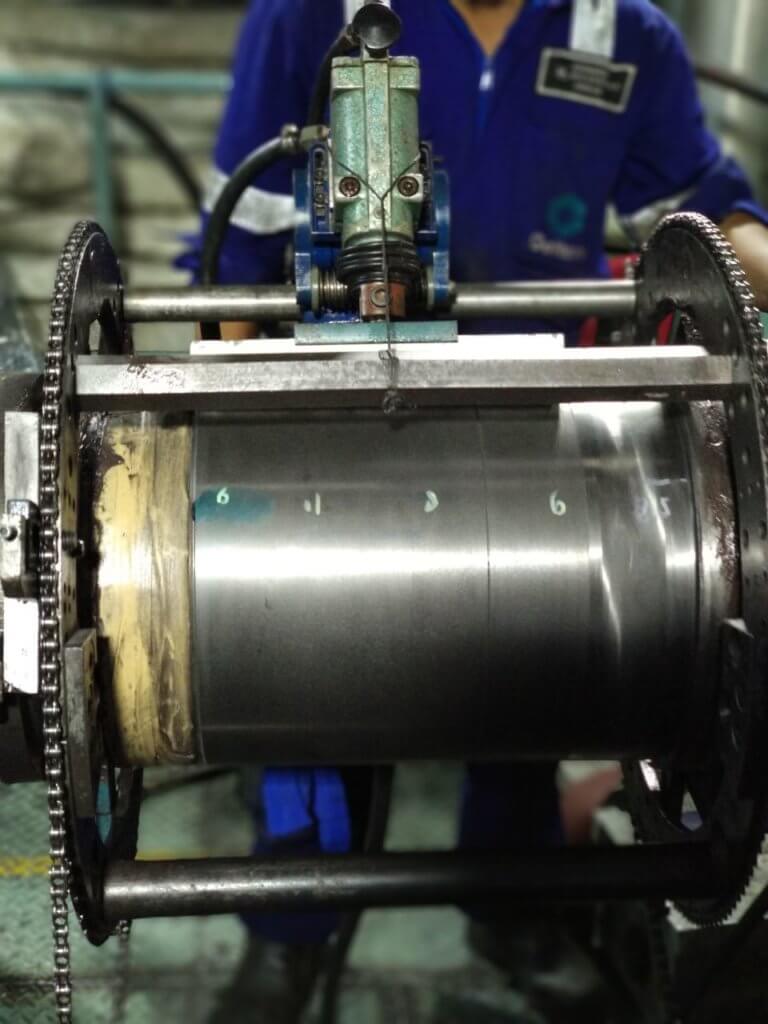

Goltens installed its journal machining tools and removed 3.30mm of material from the diameter. Goltens then deployed thermal spraying machinery to remetal the shaft diameter slightly above the 285mm original diameter. Once completed, Goltens finish machined and machine polished the running surface of the agitator shaft to the required original 285mm diameter.

SUCCESSFUL RESULTS

Goltens’ In-Place Machinists worked around the clock in two shifts to complete the job within the tight maintenance window provided by the customer. After a joint inspection verifying the diameter, surface hardness and required surface roughness, the repair was fully accepted by the customer.

Why Choose Goltens for Crankshaft Remanufacturing

Goltens stands out as the industry leader in industrial crankshaft remanufacturing. With extensive experience, cutting-edge technology, and a commitment to superior quality and reliability, we are the top choice for customers seeking the best solutions for their engine needs.

Our team of experts has successfully remanufactured thousands of crankshafts, ensuring the highest standards of precision and performance. Whether you need crankshaft repair, rebuilding, or custom remanufacturing, our experience and expertise enable us to deliver exceptional results.

At Goltens, we invest in the latest technology and equipment to ensure our crankshaft remanufacturing process is efficient, precise, and reliable. Our state-of-the-art facilities are equipped with advanced machinery and tools, allowing us to handle crankshafts of all sizes and complexities. Leveraging cutting-edge technology, we achieve the tightest tolerances and highest levels of accuracy, ensuring that your remanufactured crankshaft meets or exceeds OEM specifications.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now