RENEWAL OF CAMSHAFT CHAINWHEEL SPROCKET ON HYUNDAI-MAN 2-STROKE ENGINE

HYUNDAI-MAN B&W 10K98MC-C 2-STROKE ENGINE REPAIR AT ACHORAGE IN SINGAPORE

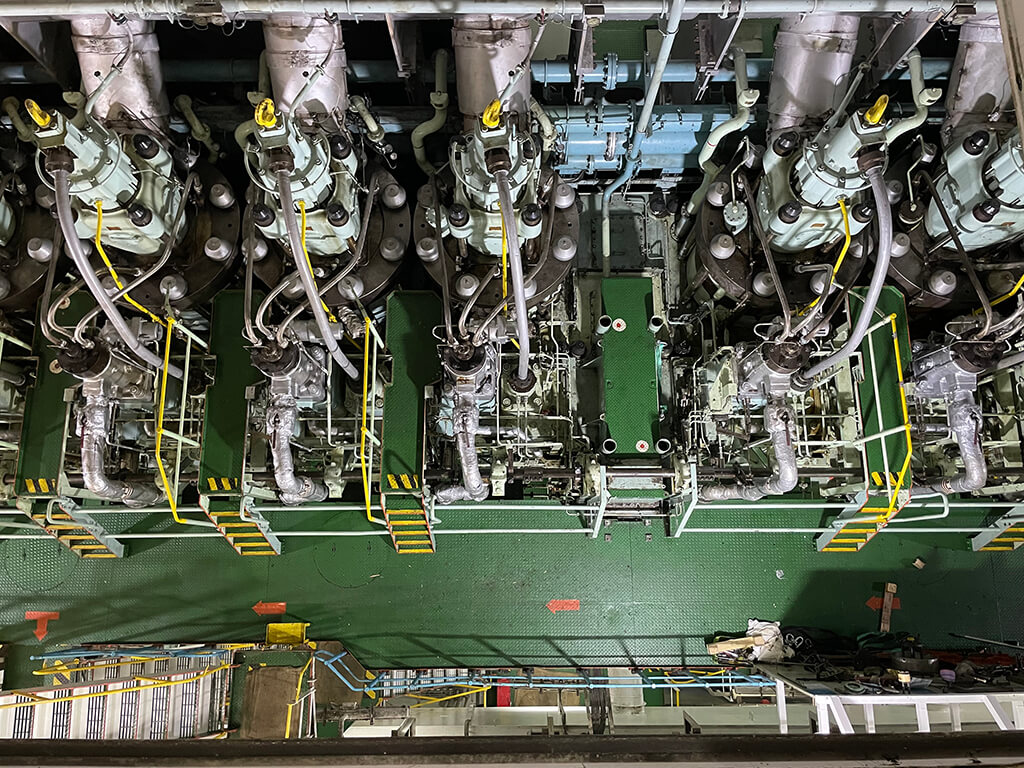

A 13-year-old, 90,000 DWT, container ship was experiencing trouble with their 98MC-C main engine’s camshaft and engaged Goltens Singapore to undertake the removal of the Camshaft Chainwheel Sprocket, removal of the shaft, machining of the bearing housing, and reassembly of the components.

Goltens’ engine specialists attended the vessel at anchor in Singapore and completed the job between the onboard attendance and work undertaken at Goltens’ workshop.

REPAIR SCOPE

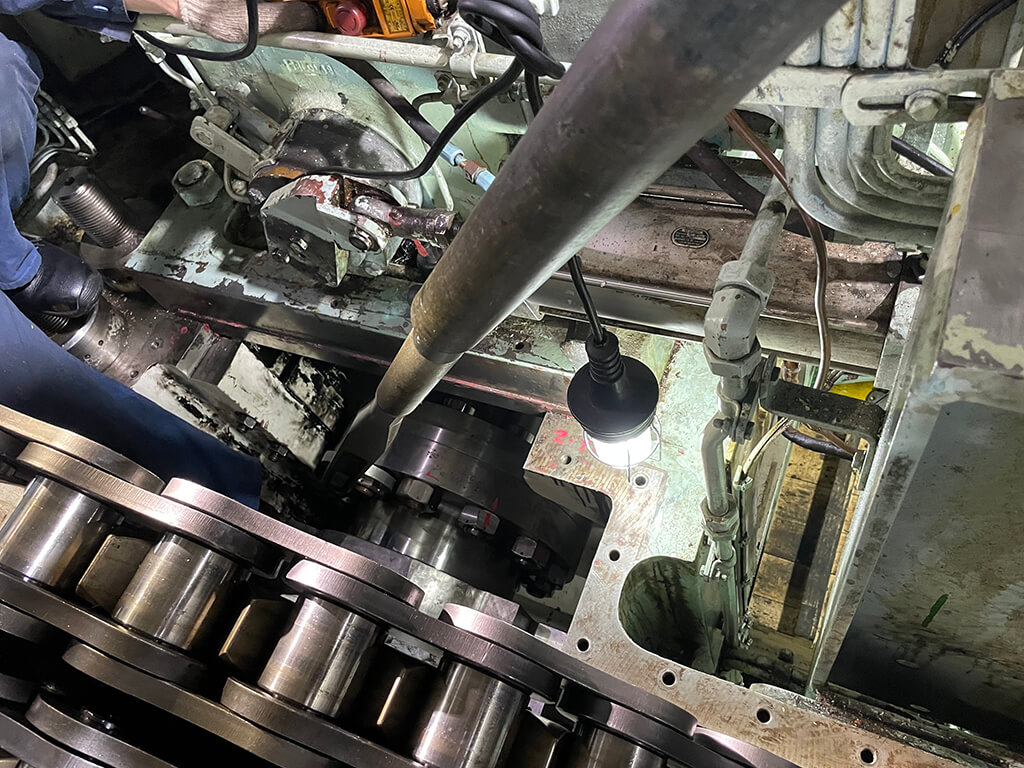

Goltens’ specialists performed a check of the injection timing before and after the chainwheel prior to removing the chain. They placed the crankshaft so that unit 1 was at top dead center before removing all the fitted bolts with hydraulic jacks. They then loosened the chain and removed the chain linkage and removed the camshaft bearing cap before removing the Chainwheel Sprocket for transport to Goltens’ workshop.

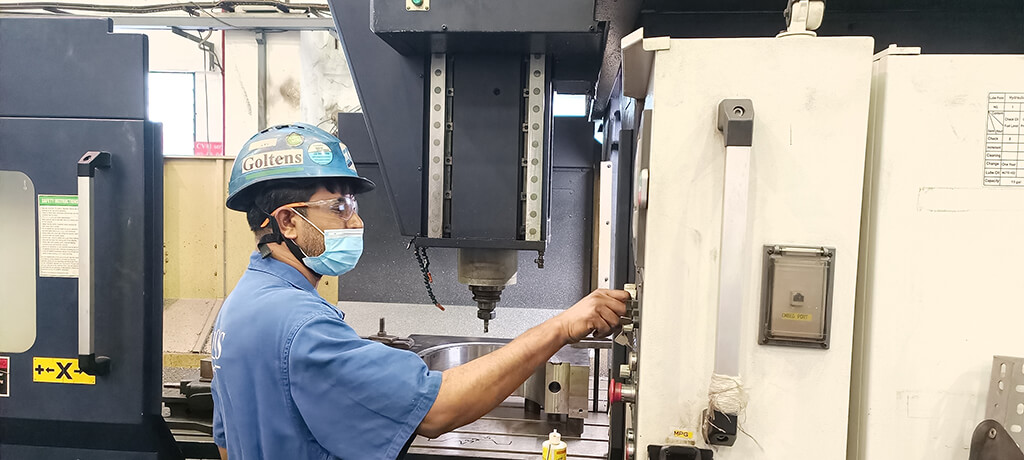

At the workshop, Goltens attempted to jack out the shaft from the sprocket but were forced to machine the shaft to remove it. Chainwheel bore and new shaft diameters were measured to calculate the interference clearance before heating the bore side to 250°C and Chainwheel side 130°C to install the new shaft. Finally, the damaged bearing housing was machined and a new thrust collar installed.

The chainwheel and bearing housing were then returned aboard and installed with shaft alignment and recentering of the bearing housing to ensure failure doesn’t recur. Bolt holes were reamed and fitted bolts installed before installing the chain linkage and adjusting the tension.

RESULTS

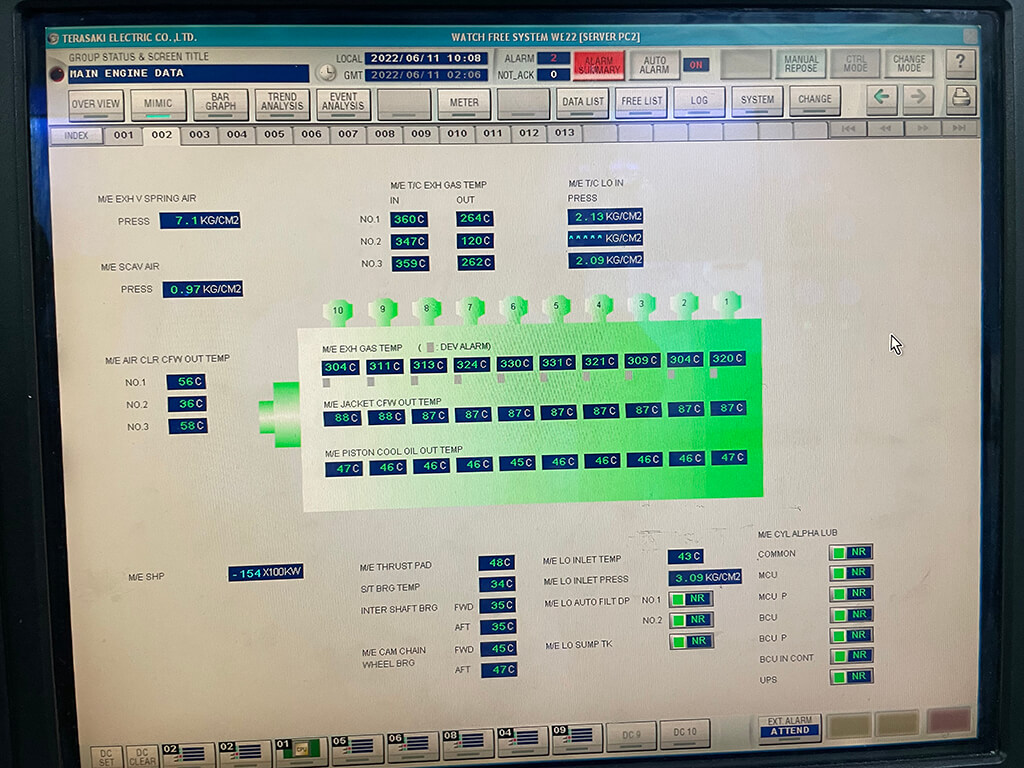

Once installation was complete, the engine timing was checked and adjusted. The engine was then turned over to the Chief Engineer and a satisfactory sea trial was completed.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now