Conical Rudder and Rudderstock Repair: On-Site and in Drydock

In-Situ and workshop machining repair

A vessel owner approached Goltens to evaluate the repair of a damaged rudderstock on its vessel in a drydock in Spain. Goltens specialists inspected the rudderstock and prepared a detailed repair procedure consisting of repairing the rudderstock in Rotterdam, machining the rudder in–situ and fabricating a stepped insert bush. The proposed process was reviewed and approved by the customer and Class.

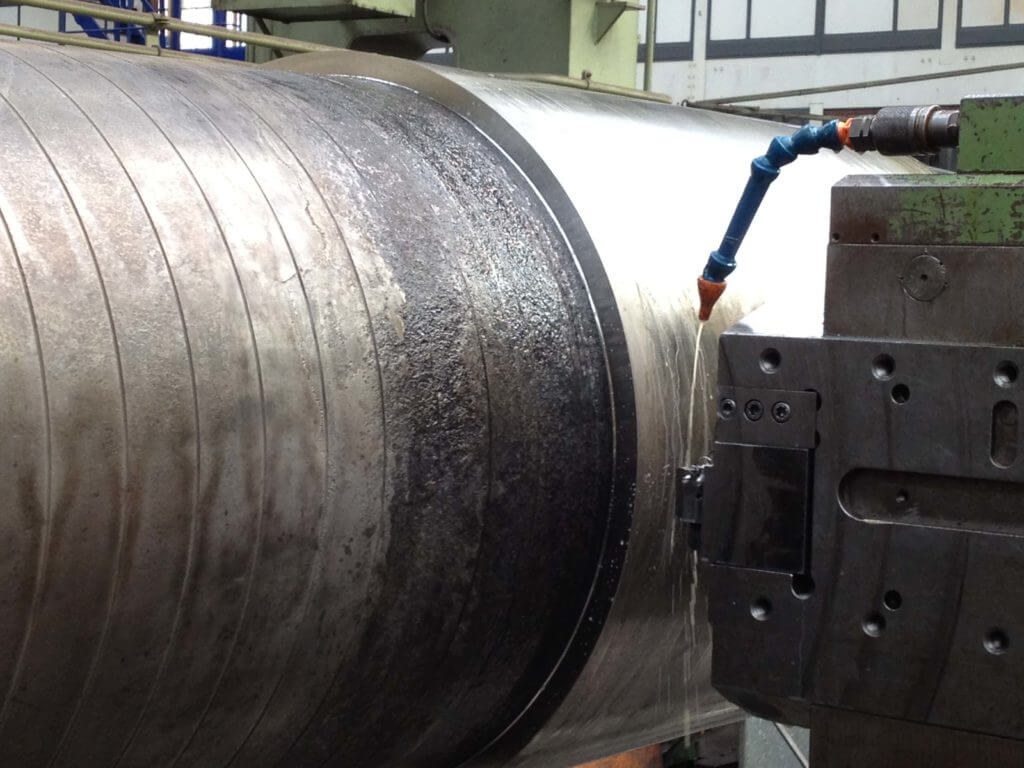

The Rudderstock, with a 1:15 taper, was inspected, cleaned and machined in the workshop. Goltens was able to save the bearing sleeve but the oil grooves and O-ring grooves required restoration. Also, the rudderstock nut was repaired and the SKF-pump ring was overhauled including a newly fabricated piston ring.

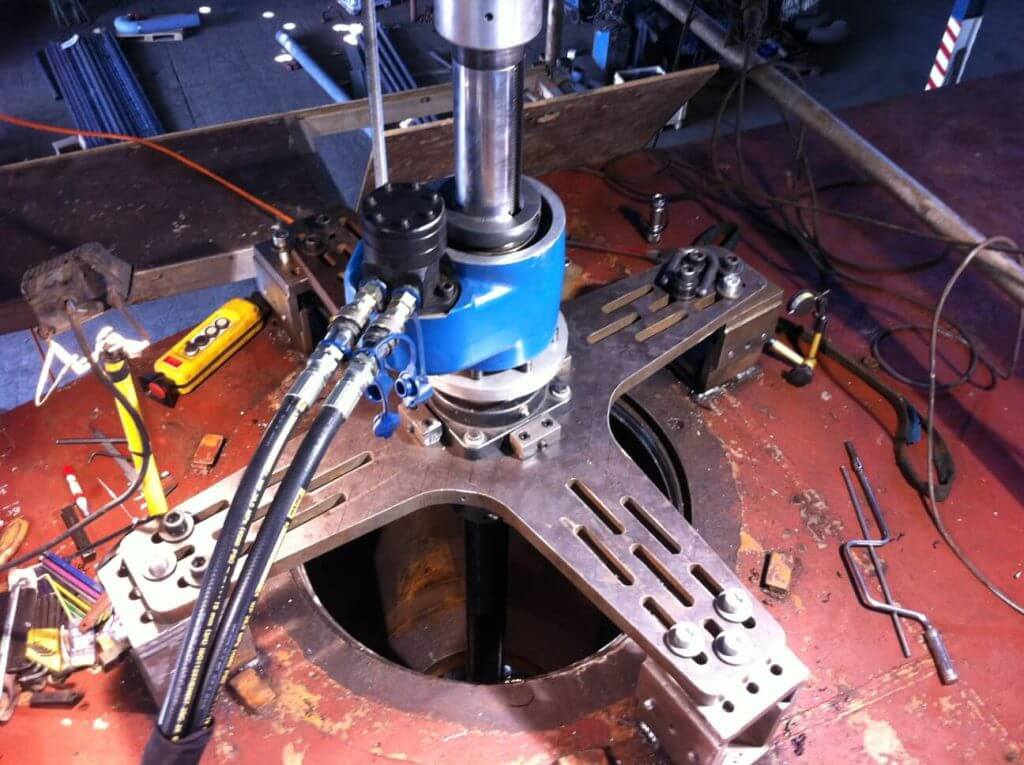

To accommodate the smaller rudderstock, the conical bore in the rudder needed to be machined to undersize and a stepped bush inserted. Goltens manufactured the bush within very tight tolerance, and the bush and the rudderstock were blue fitted in the workshop.

Onsite in Spain, Goltens In-Situ Specialists machined the rudder to a diameter of 800mm and a depth of 910mm. Goltens then used liquid nitrogen to freeze the bush and insert it in the rudder. The rudderstock was blue-fitted into the rudder and due to the precision of the machining, only two blue fits were necessary for acceptance by class.

PROJECT FACTS

| Vessel dimensions: | 175 x 30 |

| Vessel deadweight: | 31,434DWT |

| Rudderstock sizes: | 8m x ø750, 12 Ton |

| Rudder sizes: | 10x3m, 15 Ton |

REPAIRS

- Workshop machining of 1:15 taper rudderstock and restoration of oil and o-ring grooves

- Fabrication of stepped bush for insert and bluefitting with rudderstock

- In-Situ machining of Rudder (800mm dia x 910mm deep)

- Installation of stepped bush in rudder

- Blue fitting of rudderstock and bush

RESULTS

Goltens continuously monitored the entire assembly process of the rudderstock and the rudder which was completed by hydraulic press-up method. The reassembly of the rudder was successful and the vessel was returned into service 3 days before the delivery date stated in the original repair planning to the complete satisfaction of the owner and class society.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now