Shipyard Flange Machining

Precision Machining In Emerging Markets

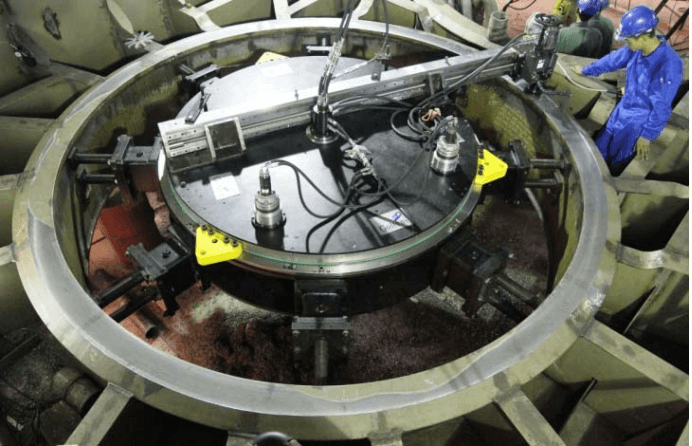

Goltens recently took delivery of the latest equipment investment by Goltens in Southeast Asia. The new orbital milling machine is capable of machining flanges of up to 6M in diameter.

Goltens already had several pieces of equipment capable of machining flanges ranging up to four meters in diameter and carries out a large number of jobs each year throughout the world, but still was looking to make the step up to an even greater offering for customers.

After testing the new machinery in its workshops, Goltens was immediately engaged by Strategic Marine Shipyard in Vietnam to machine two flange surfaces of about 4M diameter for Voith propellers on a tug boat for the Port of Napier, New Zealand.

Strategic Marine (Vietnam) General Manager, Michael McCourt, commented that “the availability of Goltens’ Orbital Milling Machine here in Vung Tau resulted in significant savings for us in both time and cost on this project. This cooperation is indicative of the synergy that can be achieved between our companies to deliver complex projects”.

FLANGE MACHINING PROJECT FACTS

| TUG BOAT FLANGES | |

|---|---|

| Equipment maker: | Voith Turbo |

| Model: | Voith Propeller |

| Foundation diameter: | 3800mm |

| Surfaces/ship set: | 2 |

| Holes per Surface: | Diameter 27mm X 72hole |

SHIPYARD FLANGE MACHINING

- Laser alignment and flatness check of the Voith propeller surface.

- In-situ machining of the top surfaces.

- Marking of the PCD and in-situ-drilling of a total of 144holes per ship set.

RESULTS

“Goltens is someone we can depend on if we need a quick and accurate service” noted the customer. Goltens technicians completed this complex job in close association with the maker relative to the finite tolerance requirements in only 5 days.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now