Slip Ring In-Place Machining Returns Coal Fired Steam Turbine To Service

43-YEAR-OLD BBC TURBINE GENERATOR

Worn slip rings compromise the transfer of current from the rotating component of the generator to the brushes. Over the course of time these can result in poor power transmission and in the worst cases arcing and potentially a ring fire resulting in a forced outage.

Goltens Rotterdam’s in-place machining experts got the call to machine two sets of slip rings on a 43-year-old BBC generator with heavily worn slip rings. Evaluation with a straight edge showed a highly uneven wear pattern across the surface of the slip rings that required rectification.

THE REPAIR

Goltens deployed its single point journal cutting tools to the site and began the process of returning the running surfaces to an even condition.

The two sets of slip rings had been subject to previous machining repairs and were of differing outside diameters before the repairs. Also, the extent of the wear on the slip rings was uneven and each set required a differing amount of material to be machined away to get to a clean, full contact surface.

- Slip Ring #1 – Original diameter of 507mm with a post machining diameter of 503.10mm (3.9mm)

- Slip Ring #2 – Original diameter of 509mm and a post machining diameter of 508.2mm (0.08mm)

THE RESULT

The entire repair was completed inside of 5 days onsite inclusive of waiting and staging. Both sets of slip rings were machined to a surface finish of 1.0Ra in accordance with the manufacturer’s specifications and the turbine generator was returned to service.

PROJECT FACTS: SLIP RING MACHINING

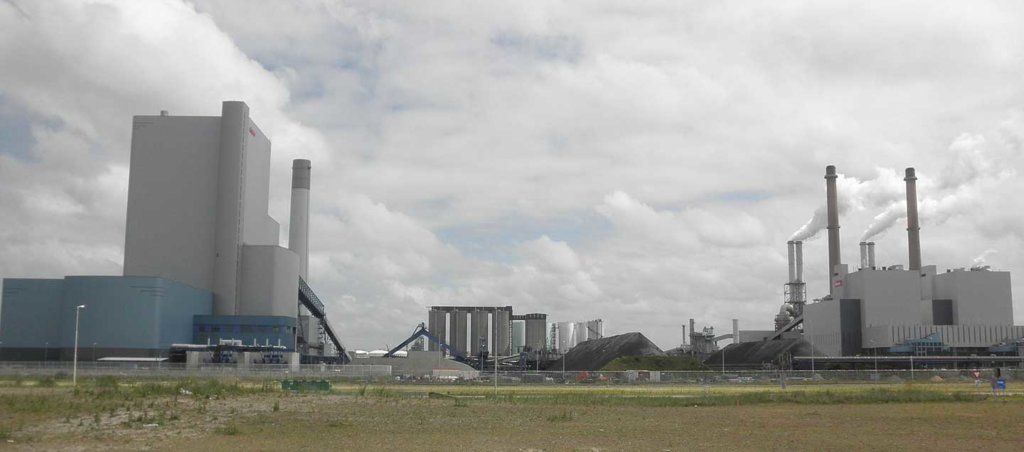

| Customer: | Coal Fired Steam Plant |

| Location: | The Netherlands |

| Turbine Manufacturer: | BBC |

| Year of Commissioning: | 1975 |

| Rated Output: | 5550MW |

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download PDF