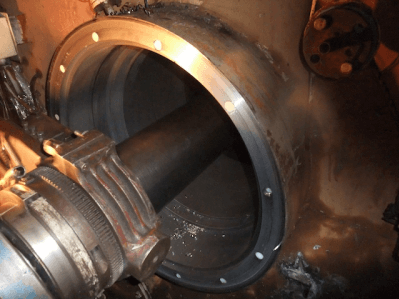

In-Situ machining of stern tube housing

Quick response and expert service allows vessel to keep its drydock schedule

Goltens received an enquiry from a shipyard in Shanghai to machine the stern tube housing on a vessel in drydock. Goltens quickly responded to the enquiry and was promptly awarded the job. Goltens immediately mobilized a team of senior In Situ machinists , laser alignment equipment and its stern tube boring machinery to the shipyard.

Goltens senior engineers discussed and clarified the job scope and Goltens’ repair procedures with the Quality Control Manager at the yard along with the owner’s superintendent and were given approval to proceed. Goltens performed a thorough inspection, boring and post boring inspection on the housing.

PROJECT FACTS

| STERN TUBE BORING | |

|---|---|

| Vessel: | M/V Cape |

| Engine: | MAN B&W 6S60MC (8,679KW) |

| Tonnage: | 73,049 DWT |

| FWD Inside Dia X L: | 658.00mm X 1250mm (+4.03mm) |

| AFT Inside Dia/Length: | 660.00mm X 660mm (+6.00mm) |

STERN TUBE HOUSING REPAIRS

- Full inspection and cleaning of stern tube housing.

- Laser alignment checking of whole propeller shaft line from flywheel of M/E to stern.

- Boring the FWD stern tube housing to oversize 4.03mm.

- Boring the AFT stern tube housing to oversize 6.00mm.

- Measuring and checking of the finial dimensions.

- Laser alignment checking of whole propeller shaft line again for double checking.

- Finish polishing by machine.

RESULTS

Goltens service team completed the whole boring process within 7 days allowing the vessel to keep to its drydock schedule.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now