Thrust Collar Bearing Machining

Hyundai MAN B&W 80MC

Goltens received an enquiry from the vessel’s owners to attend to their oil tanker’s damaged thrust collar bearing. Goltens immediately went to work on tool design and within hours the first drawings were laid out. The customized machining tools were designed and built in only 3 days working around the clock in Goltens’ machine shop.

As this was a unique and complex job, significant preparations were required and primary and secondary approaches were drawn up. Goltens deployed a team consisting of experienced diesel mechanics and expert insitu machining specialists to the ship and worked 24 hours a day to minimize the vessel’s down time.

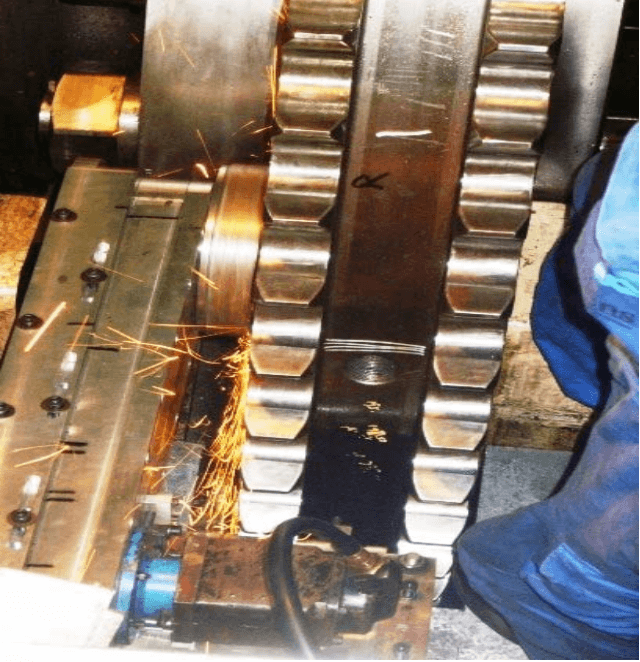

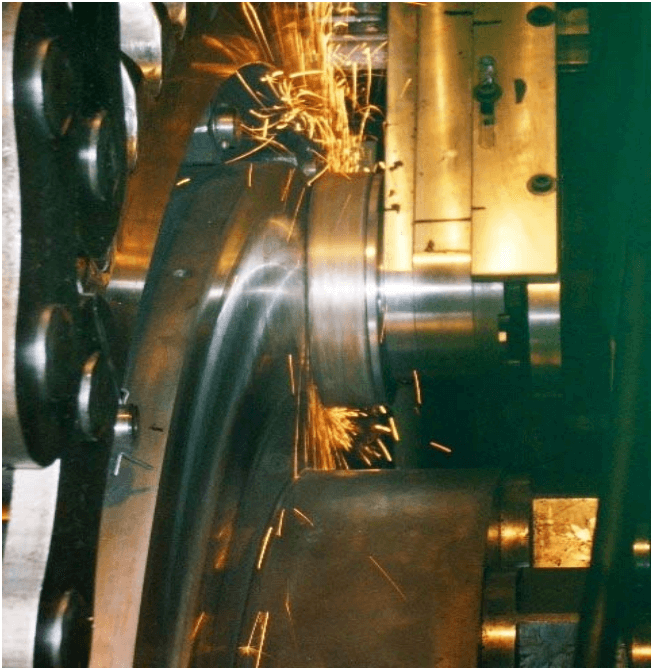

Goltens technicians dismantled the chain drive for the cam shaft prior to grinding the damaged thrust collar surface, and rebabbited the thrust bearing pads to oversize. After reassembly, Goltens completed a successful sea trial with the vessel superintendent and engine maker representative.

PROJECT FACTS

| THRUST COLLAR BEARING | |

|---|---|

| Type of vessel: | Oil Tanker |

| Equipment maker: | Hyundai MAN B&W |

| Model: | 80 MC |

| Thrust collar diameter: | 2000 mm |

| Material removed from thrust collar: | 1.5 mm |

| Material removed from thrust collar: | 1.5 mm |

| Number of thrust pads repaired: | 8 no + 8 spare |

REPAIRS

- Dismantling thrust bearings/removal of chain drive to cam shaft.

- In-situ machining of the thrust collar surface on the crankshaft.

- Inspect for high hardness on damaged collar

- Removal of all surface cracks and magnaflux inspection

- Rebabbiting of the thrust pad and final machining.

- Assembly of thrust bearing and chain drive.

RESULTS

“Goltens is someone we can depend on if we need a quick and accurate service” noted the satisfied customer. Goltens technicians completed this complex job to the finite tolerance requirements of the engine maker. The job onboard, including the thrust pad repair, was completed in only 12 days after completion of the tool design

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now