Goltens Green completes second Hyde Guardian BWT retrofit for Seaboard Marine

Goltens Miami and Goltens Netherlands team up for transatlantic BWTS retrofit

Having completed a similar retrofit for the Seaboard Atlantic in 2014, Seaboard Marine , a major container operator in Miami, again contacted Goltens Green Technologies’ specialists in Miami to undertake and manage the end-to-end retrofit of a Hyde Guardian HG250GC ballast water treatment system onboard the Seaboard Patriot.

Goltens’ team in Miami met with Seaboard to discuss the timing and scope of this second ballast water treatment retrofit project. This one was different as it included completing the installation of the system during dry- docking in Rotterdam in October of 2015.

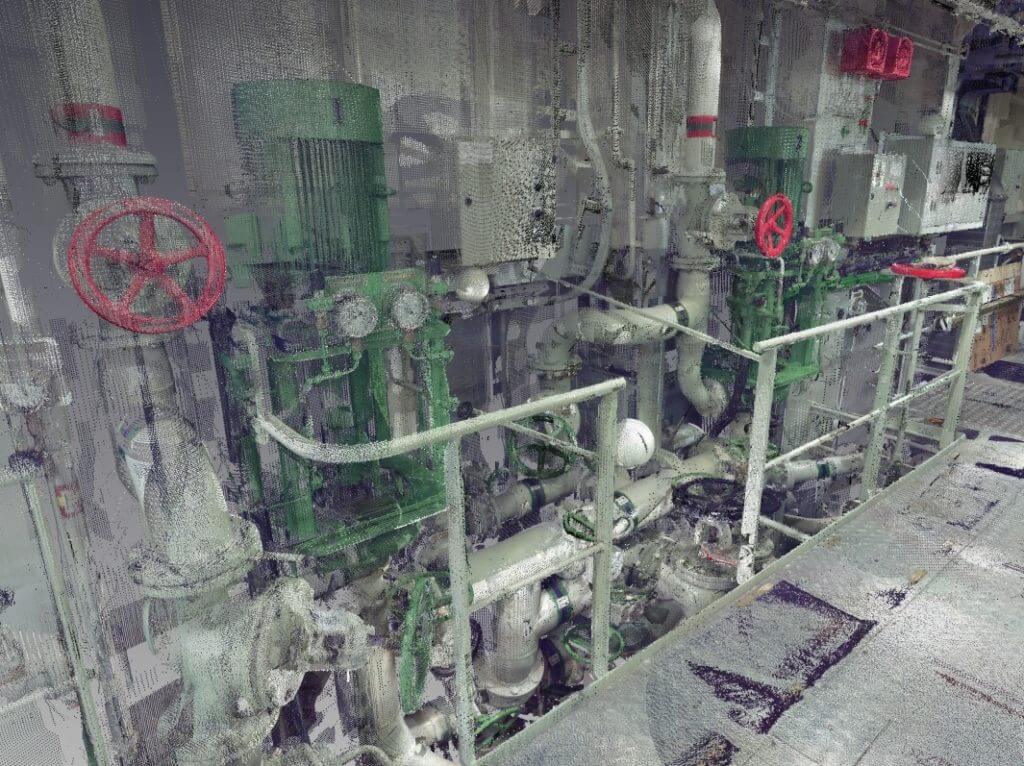

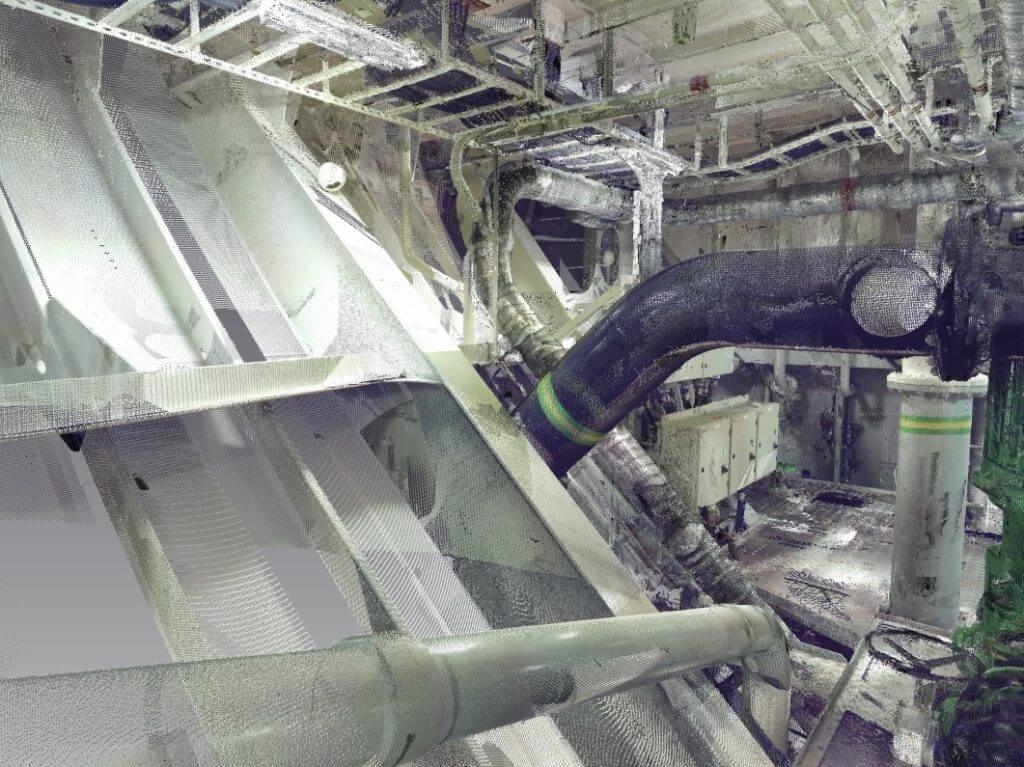

To drive project efficiencies, Goltens Green Technologies in Miami logically proposed that Goltens Green Technologies in The Netherlands manage this project. The project was started in June of 2015 with 3D scanning of the vessel while in port in Rotterdam.

PROJECT FACTS

| SEABOARD PATRIOT BWT RETROFIT | |

|---|---|

| Ballast Water System: | Hyde Guardian HG250GC |

| System Capacity: | 255 m3/h |

| Customer: | Seaboard Marine |

| Vessel Type: | Container Vessel |

HYDE GUARDIAN BWT SYSTEM RETROFIT SCOPE

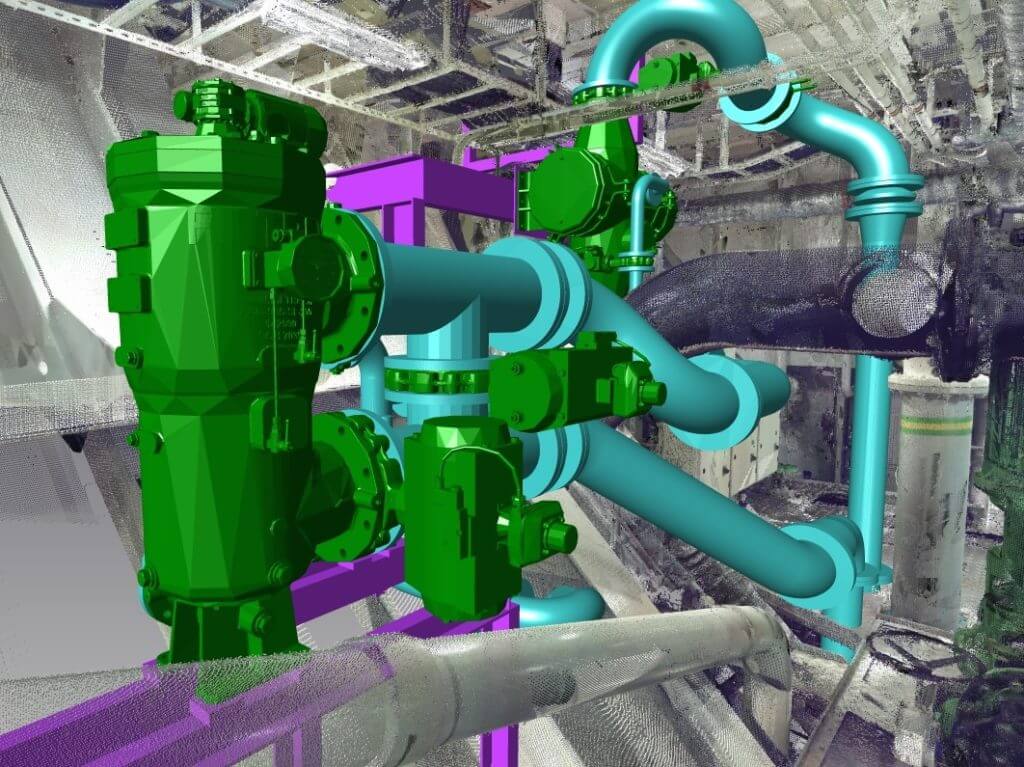

- 3D Scanning, Survey and Modeling

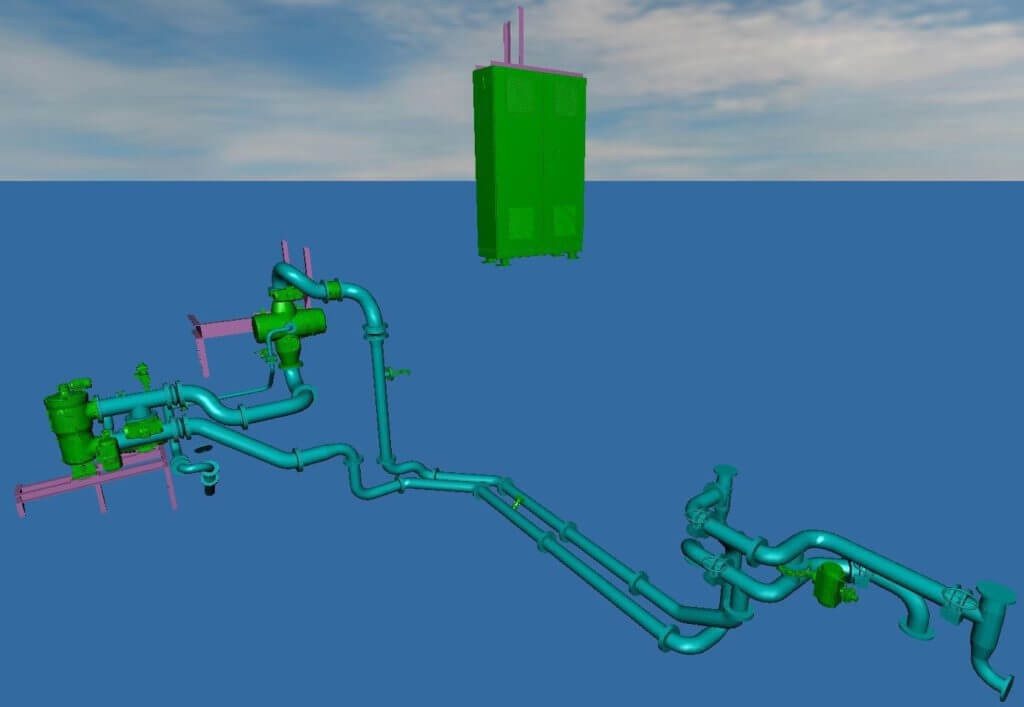

- Detailed engineering including pipe isometrics, foundation drawings and an installation manual

- Pre-fabrication of all required piping and materials

- Delivery of complete, prefabricated installation kit to shipyard in Rotterdam

- Electrical installation

- Project management and oversight of the installation in the shipyard

- Commissioning of the system with Hyde technical representative

BWT RETROFIT RESULTS

As planned, all piping and installation materials were delivered to the shipyard in September of 2015. Installation by the shipyard went smoothly and was completed and commissioned on time in October 2015. The installation was fully reviewed and approved by vessel’s class, Bureau Veritas.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now