Turn-key ballast water treatment retrofit for seismic vessel

3D scanning, design, prefabrication and installation of Optimarin ballast water treatment system

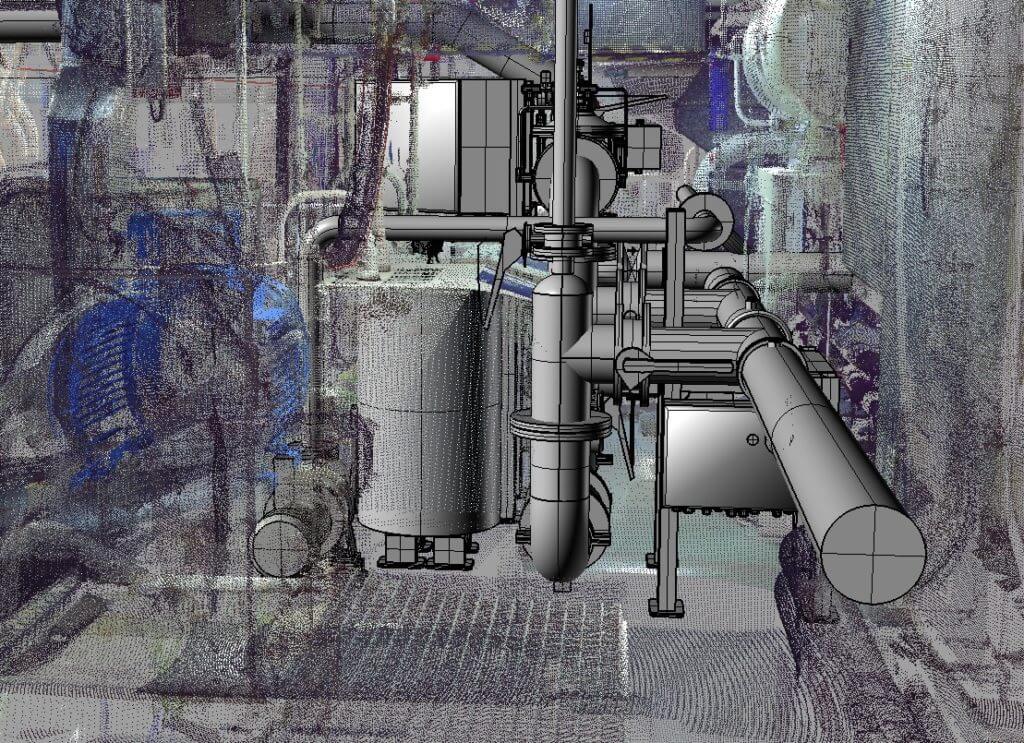

Petroleum Geo-Services (PGS), a company with 14 offshore seismic vessels, asked Goltens Green Technologies to assist in planning and installing an Optimarin ballast water treatment system onboard one of their ships, the PGS Apollo. As these ships are only in port for very short periods, getting all the information required for the later installation while it was alongside was crucial. The potential locations in the engineroom were fully scanned in Namibia in November 2012.

During the scan and space study, it was discovered that the engineroom was densely filled with assorted equipment, so different options were discussed while onboard to find possible locations for the treatment system. Once off the vessel however, PGS reevaluated the proposed location and decided it was not ideal.

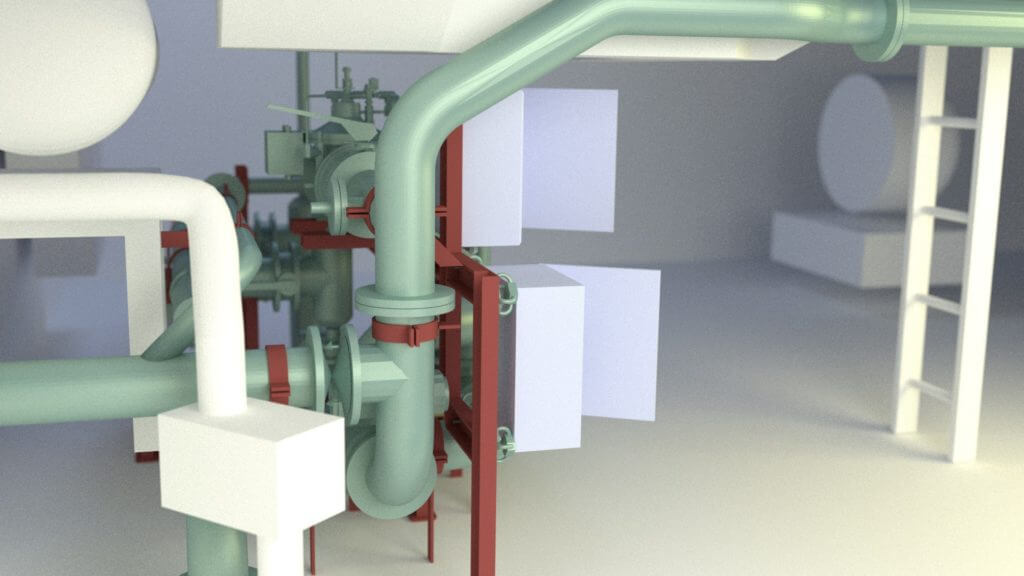

As these areas were fully covered in the 3D scans, Goltens was able to model and propose an alternative solution without having to revisit the vessel. The new solution required the movement of some existing equipment but allowed for the system to be successfully installed.

This solution was reviewed and accepted by PGS and Goltens proceeded to complete a detailed engineering package and prefabricate all required piping and components to install the system during a future maintenance stop.

PROJECT FACTS

| PGS APOLLO | |

|---|---|

| Vessel type: | Seismic vessel |

| Ballast flowrate: | 150m3/hr |

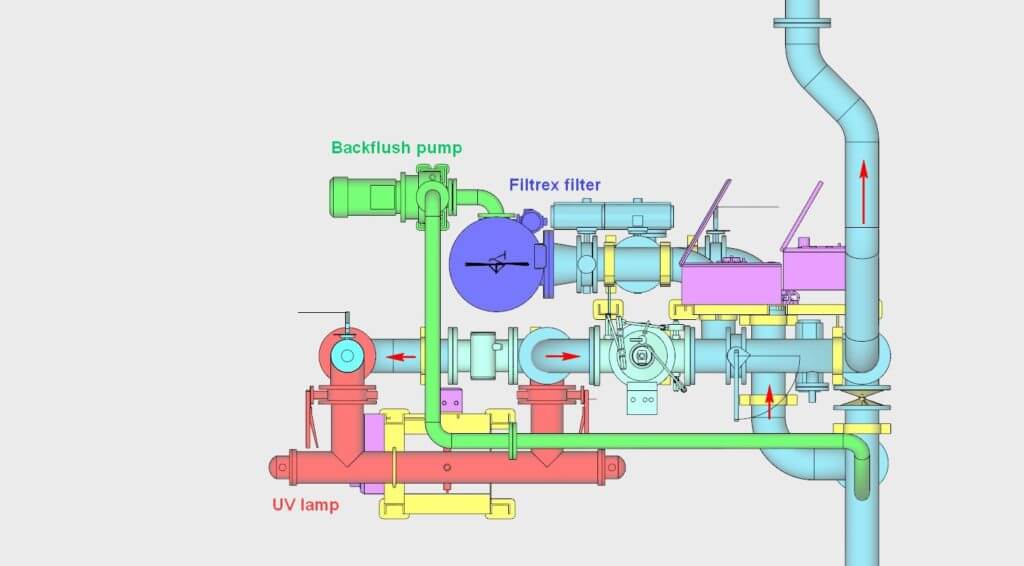

| Ballast treatment system: | Optimarin 167 m3/hr w/Filtrex filter |

BALLAST WATER TREATMENT RETROFIT WORK

- 3-D Scanning, Survey and Modeling

- Detailed engineering including pipe isometrics, foundation drawings and an installation manual

- Prefabrication of all piping and foundations

- Mechanical installation of the ballast water treatment system

BWT RETROFIT RESULTS

The mechanical installation was completed by Goltens in October 2013, during a busy 3 day port call alongside in Ijmuiden, the Netherlands. The 3-day installation once again proved the value of Goltens precise approach to scanning, design and fabrication in limiting the downtime of vessels undergoing retrofit. It would not have been possible to install the treatment system in such a short time without the precision afforded by the 3D scans and precision pipe manufacturing according to the detailed engineering drawings.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now