TurnKey Bio-UV BIO Sea installation while vessel remained in full operation

Five Goltens stations partner up for a truly global project

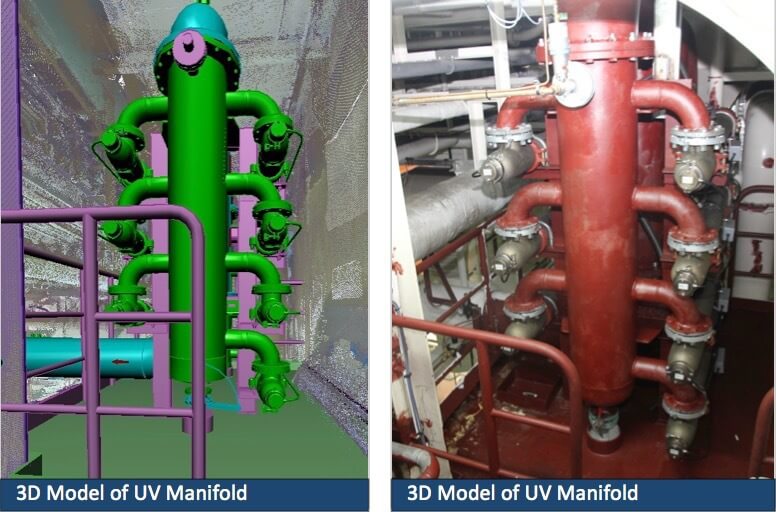

One of the world’s leading container companies approached Goltens Green Technologies in Groningen to propose a project plan to carry out the complete scope for the retrofit of a BIO UV Bio-Sea 1000 m³/hr ballast water treatment system on one of their 8,500 TEU container vessels.

As the vessel covered global routes, the ability to cost effectively engage the vessel in different regions around the globe while the vessel remained in operation was a key consideration in the award of the project.

SCANNING IN THE US / DESIGN IN EUROPE

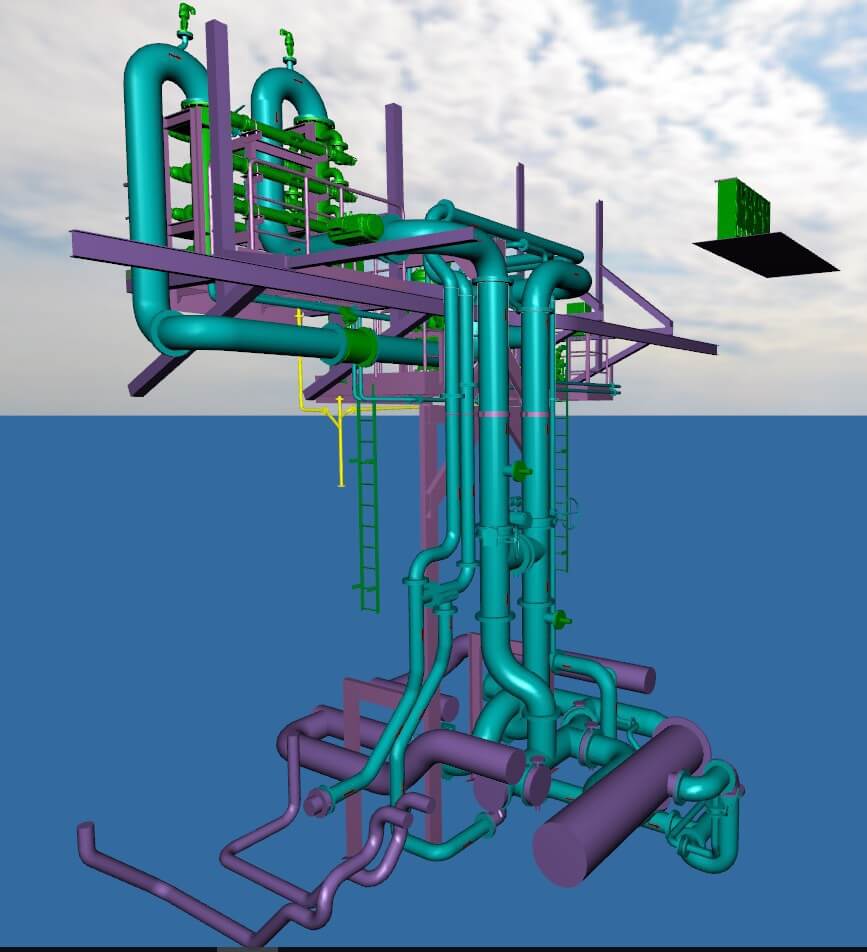

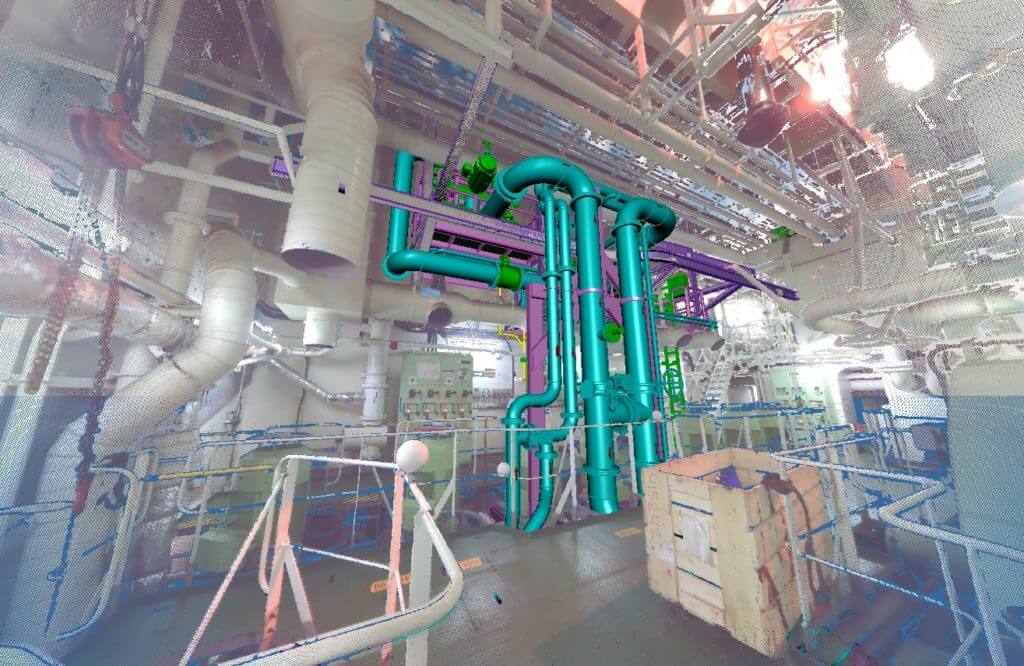

Goltens Green in Groningen arranged for laser scanning to be completed by Goltens in the USA while the vessel was alongside during a scheduled port call. The scan data was then sent back to Goltens Green in Groningen for the completion of system modelling and preparation of the detailed engineering package.

PREFABRICATION IN DUBAI

Once the design was developed and approved, Goltens planned the prefabrication and installation work. As the vessel was calling Europe, the initial plan was to prefabricate and install in Europe but trading routes shifted to the Middle East. As a result, Goltens Dubai engaged to prefabricate all piping to specification and package the retrofit kit for the installation.

RETROFIT INSTALLATION IN ASIA

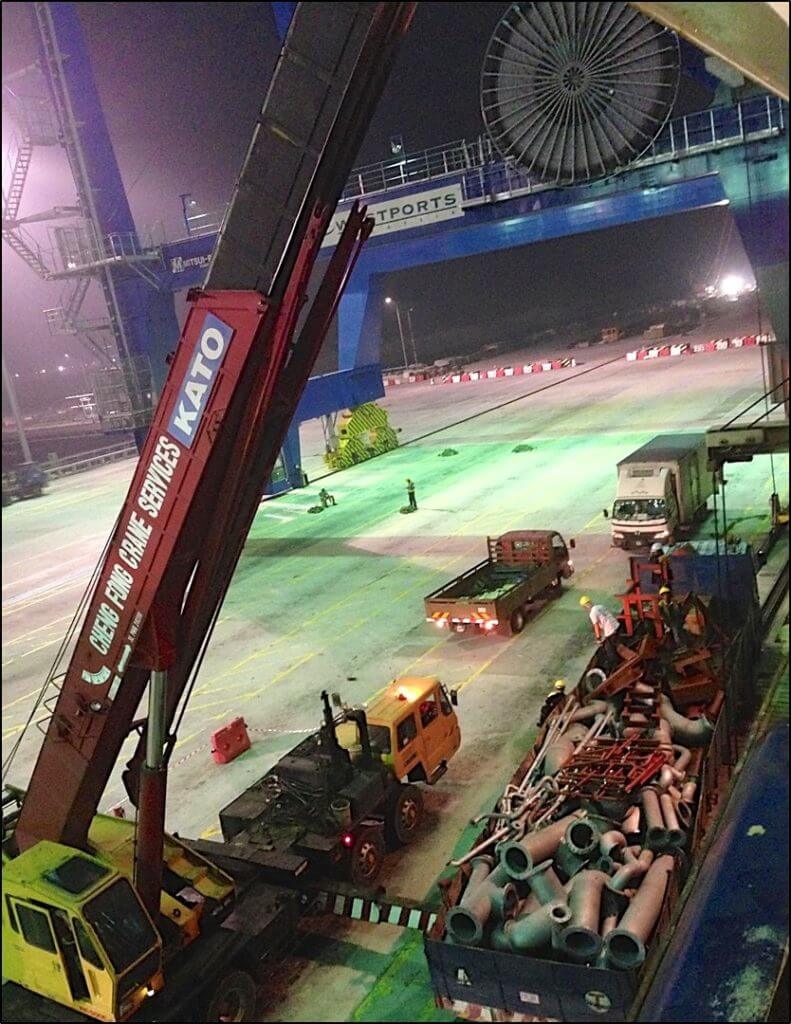

Once again, the vessel schedule changed and responsibility for the retrofit installation was then passed to Goltens Green in Singapore and an evaluation of the vessel’s schedule was done to determine the best location to engage the vessel. The retrofit package was shipped directly to Port Klang in Malaysia where the kit was brought onboard and a team of 6 Goltens technicians joined the vessel for mechanical and installation work. When the vessel reached Shanghai an additional team of 5 electricians from Goltens Shanghai joined the vessel and completed the electrical work in parallel with the remaining piping work required prior to commissioning the system.

COMMISSIONING

A Service Engineer from Samsung joined the vessel at anchor in Shanghai for the purpose of integrating the new BWTS system into the existing ship’s ballast control system and the BIO UV engineer validated all electrical connections prior to performing commissioning checks and testing on the installed system.

PROJECT FACTS

| BIO UV BWT Retrofit | |

|---|---|

| Ballast Water System: | BIO UV Bio-Sea |

| System Capacity: | 1000 m³/hr |

| Vessel Type: | Container Vessel |

| Capacity: | 8,500 TEU |

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now