Turnkey Retrofit for EGCS SOX Scrubber & BWTS

QUICK RESPONSE AND FOCUSED EXECUTION ENABLE LPG OPERATOR TO MEET EMISSIONS AND BALLAST WATER COMPLIANCE

A prominent LPG Tanker owner engaged Goltens Green Technologies division in Singapore to undertake a turnkey project for the simultaneous installation of an exhaust gas cleaning system/Sox Scrubber (EGCS) and a Ballast Water Treatment System (BWTS) to comply the IMO regulations.

The shipowner planned ahead and commenced the project 6 months before the planned docking at a Chinese shipyard. The time allotted allowed for a smooth and highly collaborative engineering process and successful completion of this complex multi-system project.

SCOPE OF WORK:

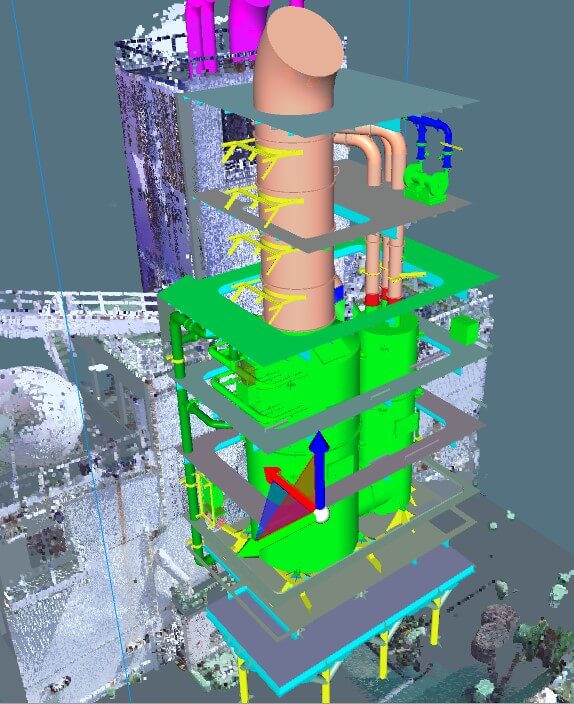

- 3D scanning & vessel survey

- Basic and detailed engineering

- Class approvals & Shipyard Management

- Procurement & Prefabrication

- Turnkey Project Management

- Installation supervision

DESIGN & ENGINEERING:

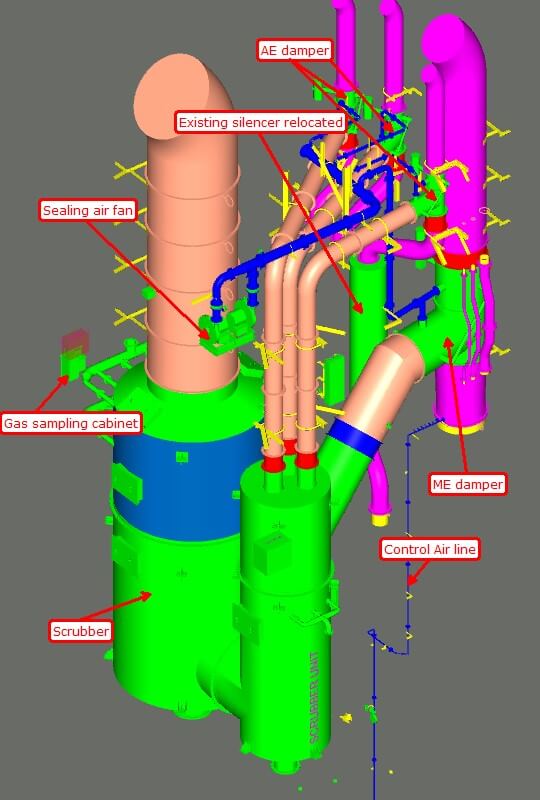

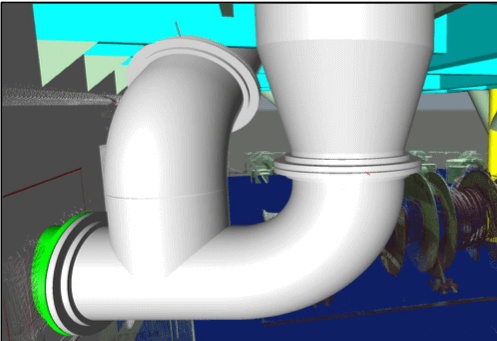

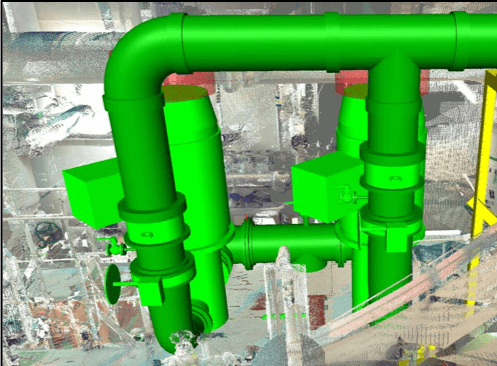

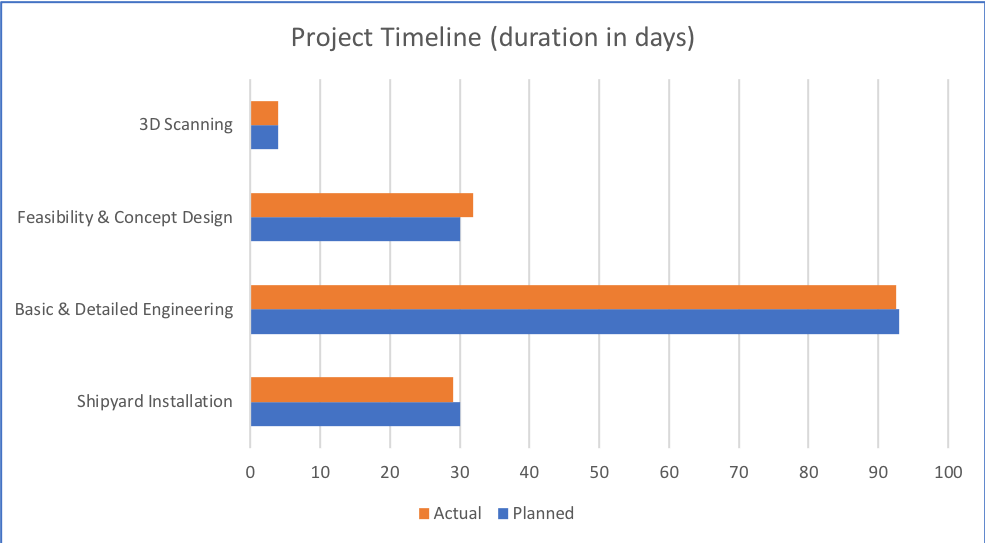

Goltens’ retrofit survey team undertook the onboard survey and 3D laser scanning in less than 4 days. From the outset, the primary constraint of the scrubber part of the project was the limited size of the existing funnel, and the physical size and configuration of the U-Type venturi scrubber chosen. A major extension to the funnel was identified by all parties as the only viable option.

Goltens’ design engineering team, working closely with Kwang Sung and the vessel owner, identified the most efficient approach to minimize the extent of the required extension. The innovative design delivered managed to retain a somewhat streamlined and aesthetically pleasing “backpack” arrangement.

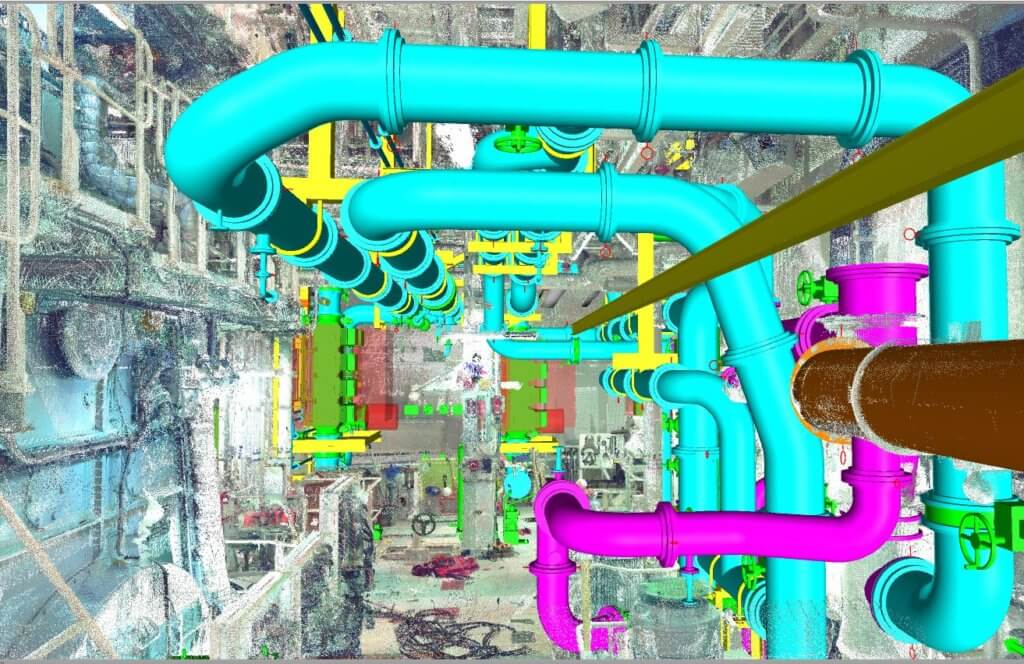

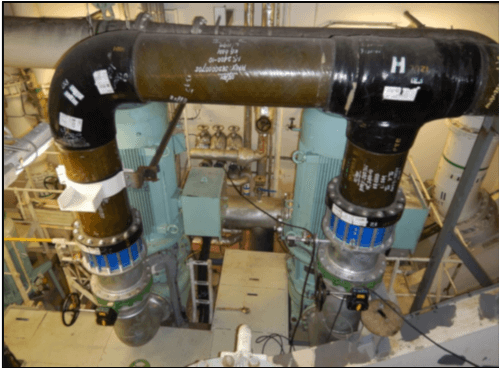

Given the compact engine room and lack of free space on the engine floor level, locating the Scrubber SW supply pumps, associated equipment and ECU units for the BWTS was also a challenge.

Production design & class approval were completed efficiently, topping off a successful retrofit design project that took 4,700 manhours from contract award to delivery of production design drawings.

INSTALLATION PHASE: 12,500 MANHOURS/29 DAYS

Goltens’ deployed three highly experienced engineers to supervise structural, piping and electrical disciplines at the Chinese shipyard. Over the course of the next 29 days, Goltens successfully managed site supervision of 12,500 manhours applied to shipyard jobs for the BWTS and Scrubber retrofits.

PROJECT SUCCESS RESULTS IN FOLLOW ON WORK:

Goltens worked closely with the owners to avoid any delays to schedules which came from technical obstacles encountered and delivered the project ahead of schedule.

As a result of the successful completion of the job, the owner decided to award three follow on Scrubber/BWTS retrofit projects to Goltens. Another validation point for Goltens’ well tested and well executed retrofit process.

TECHNICAL DESCRIPTIONS:

|

Vessel Length (LOA) |

225.28 m |

|

Vessel DWT |

82.000 |

|

Built Year &Yard |

2009 – DSME, Korea |

|

Gross Tonnage |

47,276 |

|

Main Engine |

B&W 6S60MC-C |

|

Max Engine Power |

13,560 kW |

|

Aux Engines (3Nos) |

Hyundai 8H21/32 |

|

Aux Engine Power |

1280 kW |

|

BWTS |

Alfa Laval PureBallast 3.1- 750 (2 sets) |

|

Ballast Pump |

800 m3/h x 2 sets |

|

Scrubber Type |

Kwang Sung Open Loop |

|

Scrubber Dimension (m) |

7.05L x 4.0D x 10.55H |

|

Max. Design Exhaust gas flow |

137,709 (kg/hr) |

|

SO2 Compliance Level |

0.5 % Non-ECA |

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now