Crankshaft replacement, line boring & rebuild for Wartsila 12v46 engine

Careful planning and execution allows for uninterrupted operation onboard Royal Caribbean cruise ship

Royal Caribbean Cruises Ltd. contacted Goltens Singapore to evaluate whether a crankshaft replacement could be undertaken onboard one of its vessels without impacting operations or delaying its planned movements.

One of the vessel’s 5 Wartsila 12V46 main engines had suffered a main journal failure and the cracks found were deeper than maximum allowed undersize by engine maker requiring a replacement of the crankshaft. It was also discovered that during the main bearing failure a lot of heat was transferred to the bearing saddle causing it to collapse. As a result, In- Situ line boring of the main bearing pockets was also required to restore the engine back to running condition.

Goltens mobilized one of its most experienced Repair Managers to conduct an inspection during a port call in China to evaluate the logistics for the repair and options for onloading the replacement shaft.

The Planning

Goltens performed an on-site inspection and reviewed AutoCAD drawings of the engine room and overlaid the dimensions of the 9 meter/15 ton replacement crankshaft along the potential route. The evaluation showed that there would be just enough space to shift the crankshaft between the forward and aft engine rooms via the water tight door with only a few centimetres of clearance without cutting the watertight door. This evaluation was critical as the watertight door would have needed to be 100% restored prior to sailing and the 10 hour port stay in Singapore was not long enough to complete all required work.

Complicating matters, the engine room was located 80 meters from the service / cargo entrance where the replacement crankshaft would be loaded onboard. This alleyway is critical to the efficient transfer of provisions and luggage the roughly 2,500 passengers and crew of the vessel. With the port call lasting only 10 hours, completing the transfer of the crankshaft without interrupting these critical transfers or interrupting the movement of the vessel was a logistical nightmare that would require very precise timing and execution.

Offloading the condemned crankshaft was not as critical as it could be cut into smaller sections and offloaded more easily without time constraints via the water tight door in Singapore.

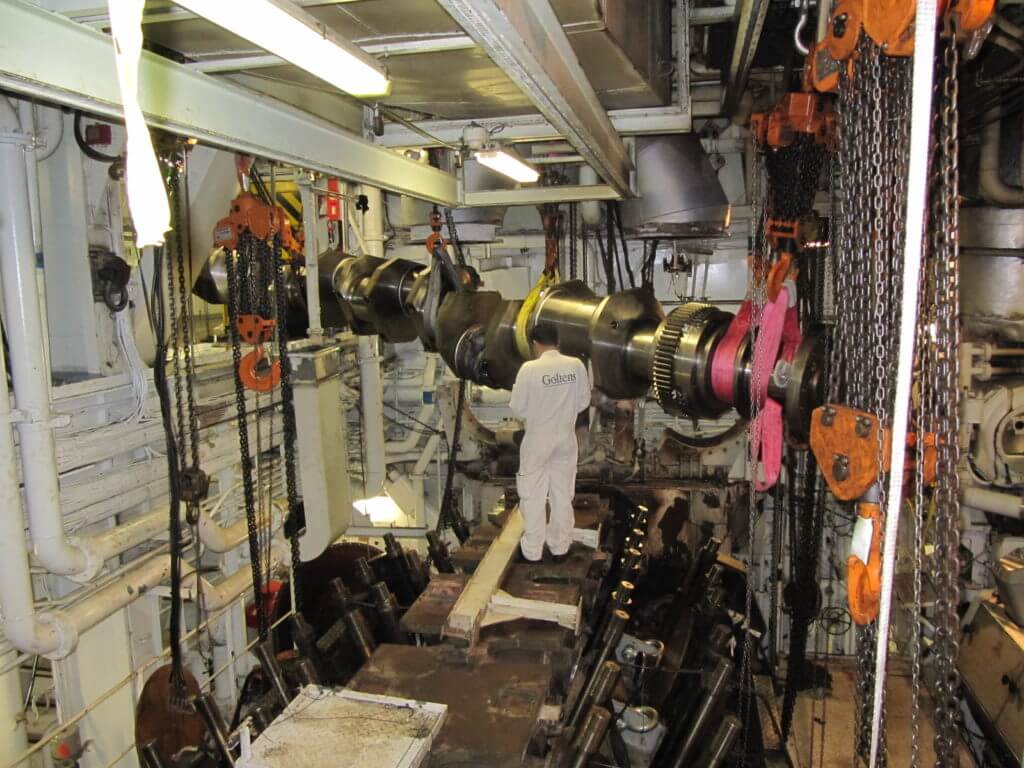

The Rigging

The proposed process was reviewed by Royal Caribbean’s Class, Det Norske Veritas, and Royal Caribbean accepted the proposal and Goltens mobilized to complete the repair as quickly as possible.

Careful planning and preparation work was done including removal of a portion of the overhead ceiling in the aft engine room and all piping and cabling to allow for access from the service alley way one deck above the aft engine room before the rigging operation commenced.

The operation to onload the new crankshaft started from shore side in Singapore at 0800 hrs and the crankshaft was transferred onboard via the provision doors at 0900 hrs. Now the race was on to get the crankshaft shifted 80 meter in the service alley way as quickly and safely as possible as the passengers had started to board and all luggage had to be shifted in the same alley way. Two hours later the crankshaft was in place, 80 meter inside the vessel and the luggage and provision movement could start on the scheduled time.

As the vessel could not sail with open holes in the alleyway deck, the deck cutting and lifting operation had to be completed at the next port of call, a 12-hour stay in Port Klang, Malaysia.

As soon as the vessel reached port, Goltens’ welders cut the access hole in the deck and began the rigging operation to lower the 15-ton crankshaft into the engine room. Once the crankshaft was lowered, the hole was immediately welded shut and quality checked and the vessel sailed on time. This operation went smoothly and the new crankshaft was soon hanging over the engine where it would be installed.

In-Situ Line Boring, Installation and Rebuild

In parallel, Goltens carried out In-Situ line boring of the damaged main bearing pocket. A new undersize saddle was supplied and installed in the engine and machined back to original size keeping all main bearings standard size and eliminating the need for special bearings.

Once the crankshaft was installed, all clearances were checked and found satisfactory and the engine was rebuilt. All auxiliary equipment had been fully overhauled by ship’s crew and Goltens technicians. As part of the rebuild Goltens replaced original rubber cushion mountings with a newer improved design of spring mountings. After alignment of the engine was carried out the engine was ready for operational testing.

PROJECT FACTS

| CRANKSHAFT REPLACEMENT | |

|---|---|

| Type of vessel: | Cruise Vessel |

| Engine Make/Model: | Wartsila 12V46 |

| Length of crankshaft: | 9 meter |

| Weight of crankshaft: | 15 Metric Ton |

| No of main engines: | 5 |

SCOPE OF DIESEL ENGINE REPAIRS

- Dismantling of engine and removal of crankshaft

- Rigging condemned shaft from vessel

- Rigging replacement crankshaft onboard

- Cutting and welding of passageway deck for crankshaft movement

- In-Situ Line Boring of damage bearing pocket to standard size

- Overhaul of ancillary equipment with ship’s crew

- Reassembly of engine

- Laser Alignment of engine and replacement of cushion mounts

- Operational testing and handover of engine

RESULTS

A performance test and tune up test was completed by Goltens technicians. All 12 cylinders were adjusted such that all exhaust temperatures and peak pressures were in perfect balance and the vessel was able to take the engine back in operation within the agreed project time. The entire process was completed to the satisfaction of the owner and class surveyor (De Norske Veritas) and there was no interruption to the vessel’s schedule or disruption to its passengers.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now